Method for preparing beta-silicon nitride whiskers

A silicon nitride whisker and silicon nitride powder technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve environmental pollution, low purity of silicon nitride whiskers, harsh reaction conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

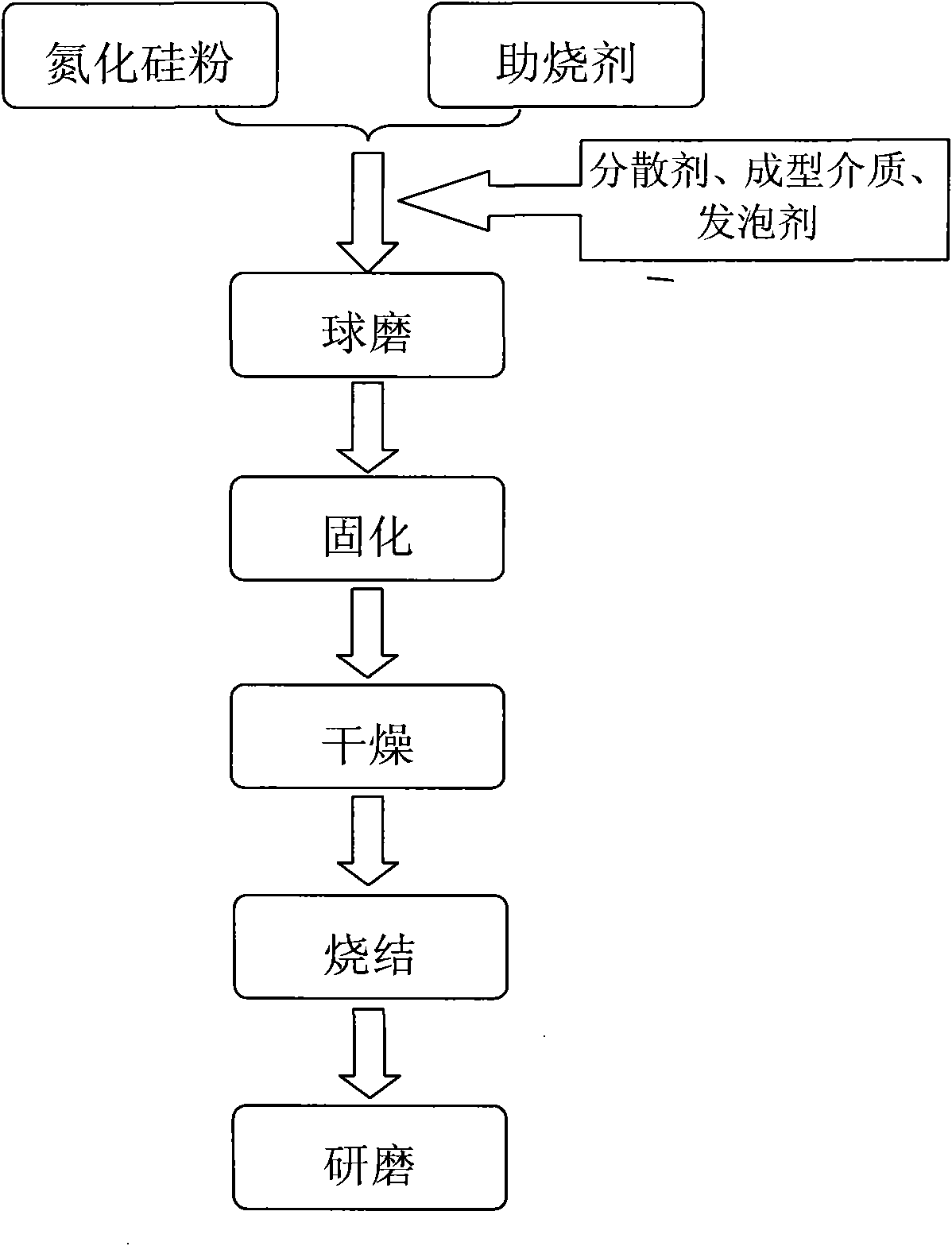

Method used

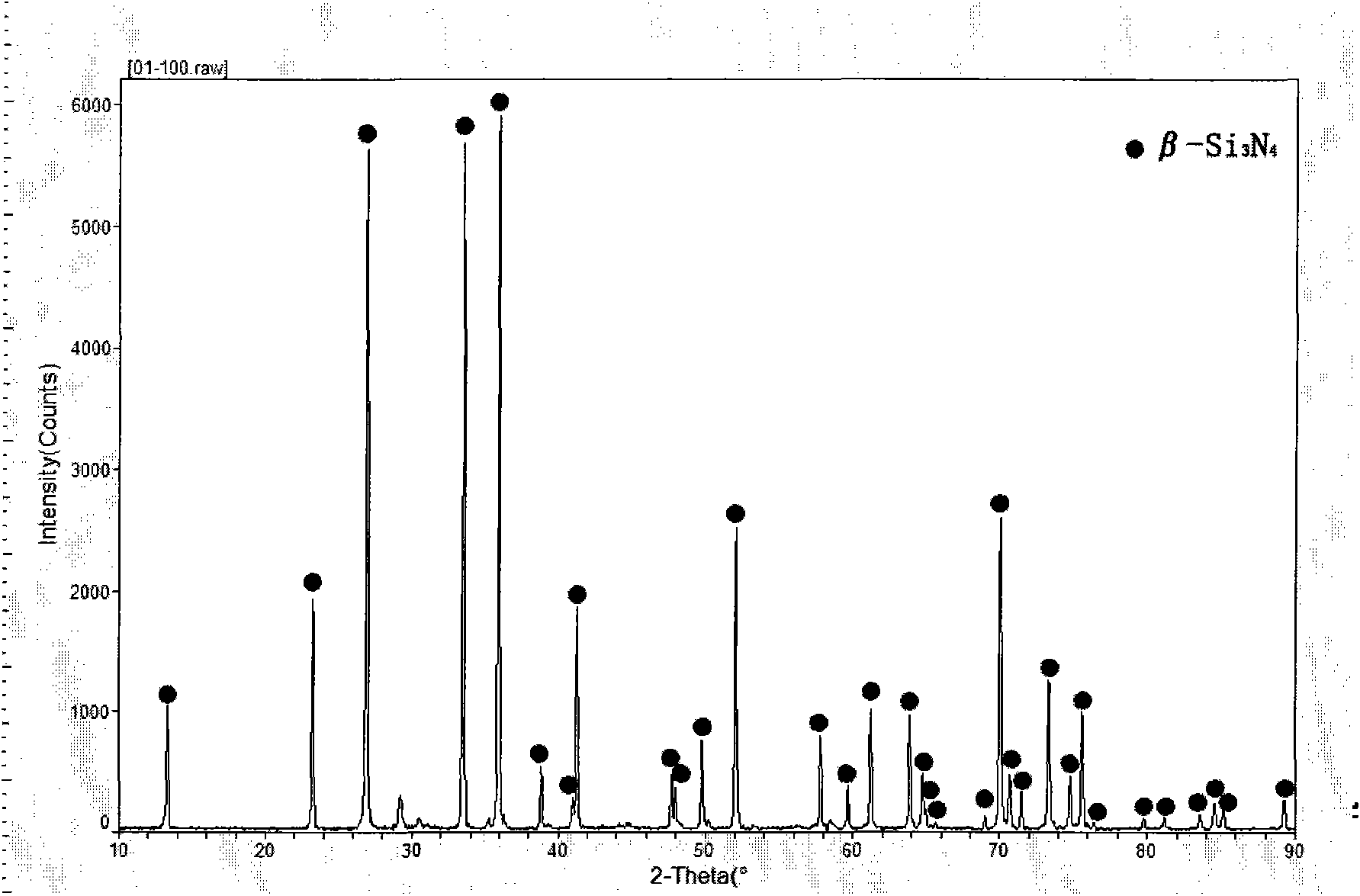

Image

Examples

Embodiment 1

[0048] Add 59.5g of silicon nitride powder to 80mL of deionized water, add 2.5% of silicon nitride powder, 1.66g of alumina powder and 4.92g of 7.5% yttrium oxide powder, and 0.66g of alkaline water agent as a dispersant. The forming medium is PVA, and it is calcined at 1650°C and kept for 2 hours to obtain silicon nitride whiskers.

Embodiment 2

[0050] Add 112g of silicon nitride powder to 80mL of deionized water, add 2.5% of silicon nitride powder, 2.8g of alumina powder and 8.4g of 7.5% yttrium oxide powder, and 1.12g of ammonium citrate TAC as a dispersant. The molding medium is PVA, and it is calcined at 1750°C and kept for 2 hours to obtain silicon nitride whiskers.

Embodiment 3

[0052] Add 59.5g of silicon nitride powder to 80mL of deionized water, add 2.5% of silicon nitride powder, 1.66g of alumina powder and 4.92g of 7.5% yttrium oxide powder, and 0.66g of alkaline water agent as a dispersant. The molding medium is PVA, and it is calcined at 1650°C for molding, and kept for 2 hours to obtain silicon nitride whiskers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com