Method for carrying out modification on real-silk fabrics by using butyl titanate

A technology of silk fabrics and butyl titanate, which is applied in the direction of titanium oxide/hydroxide, titanium dioxide, animal fibers, etc., can solve the problems of silk fabrics such as anti-ultraviolet, low antibacterial performance, and long-lasting washing resistance, and achieve saving Effect of raw materials, prevention of yellowing of fabrics, optimization of finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

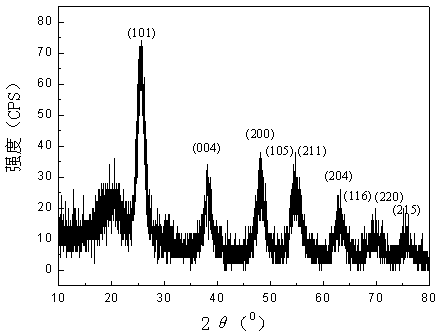

Image

Examples

Embodiment 1

[0030] Weigh 1g of silk fabric and treat it with 1.5g / L soda ash and 1g / L sodium silicate solution for 10min at 90°C and pH 10 at a bath ratio of 1:30, then wash with hot water at 60°C for 10min. Wash with cold deionized water for 10 minutes, and dry at 40°C; weigh 0.1g of butyl titanate, dissolve it with deionized water at a ratio of 1:120, and then immerse the silk fabric in the aqueous solution of butyl titanate for 1min, Add the fabric together with butyl titanate solution into a 200ml high-temperature and high-pressure reactor, and fill it with deionized water to 60% of the volume of the reactor, and keep the sealed reactor at 90°C for 5 hours at a constant temperature; after the reaction is completed, Wash with 2g / L solid soap flakes and 2g / L soda ash solution at a bath ratio of 1:30 at 40°C for 10 minutes, then wash repeatedly with cold water, and dry naturally.

[0031] According to the national standard GB / T 8629-2001, the silk fabric after hydrothermal modification o...

Embodiment 2

[0033] Weigh 1g of silk fabric and treat it with 1.5g / L soda ash and 1g / L sodium silicate solution for 10min at 90°C and pH value 10 at a bath ratio of 1:50, then wash with hot water at 60°C for 10min. Wash with cold deionized water for 10 minutes, and dry at 40°C; weigh 0.5g of butyl titanate, dissolve it in deionized water at a ratio of 1:100, and then immerse the silk fabric in the aqueous solution of butyl titanate for 5 minutes. Add the fabric together with the butyl titanate solution into a 200ml high-temperature and high-pressure reactor, and fill it with deionized water to 70% of the volume of the reactor, and keep the sealed reactor at 100°C for 4 hours at a constant temperature; after the reaction is completed, Wash with 2g / L solid soap flakes and 2g / L soda ash solution at a bath ratio of 1:40 at 60°C for 30 minutes, then wash repeatedly with cold water and dry naturally.

[0034] According to the national standard GB / T 8629-2001, the silk fabric after hydrothermal m...

Embodiment 3

[0036] Weigh 1g of silk fabric and treat it with 1.5g / L soda ash and 1g / L sodium silicate solution for 10min at 90°C and pH value 10 at a bath ratio of 1:40, then wash with hot water at 60°C for 10min. Wash with cold deionized water for 10 minutes, and dry at 40°C; weigh 0.2 g of butyl titanate, dissolve it in deionized water at a ratio of 1:120, and then immerse the silk fabric in the aqueous solution of butyl titanate for 3 minutes. Add the fabric together with the butyl titanate solution into a 200ml high-temperature and high-pressure reactor, and fill it with deionized water to 80% of the volume of the reactor, and keep the sealed reactor at 120°C for 3 hours at a constant temperature; after the reaction is completed, Wash with 2g / L solid soap flakes and 2g / L soda ash solution at a bath ratio of 1:50 at 60°C for 15 minutes, then wash repeatedly with cold water and dry naturally.

[0037] According to the national standard GB / T 8629-2001, the silk fabric after hydrothermal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com