High-concentration erbium aluminum co-doped amplifying optical fiber based on atomic layer deposition technology and manufacturing method thereof

An atomic layer deposition, high-concentration technology, applied in the direction of multi-layer core/cladding fiber, cladding fiber, coating, etc. Eliminate problems such as annihilation, and achieve the effect of simple structure, high amplification efficiency, and wide gain spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

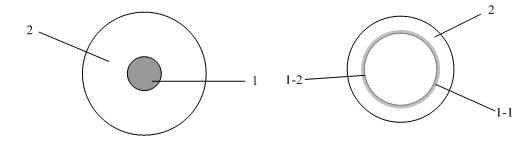

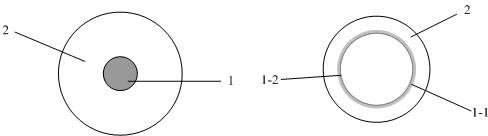

[0022] see figure 1 , The present invention is a high-concentration erbium-aluminum co-doped amplifying fiber based on atomic layer deposition (ALD) technology, which consists of two parts: core (1) and cladding (2). The material of the core (1) is also composed of two parts, pure silica loose layer or doped with a small amount of high refractive index GeO 2 The loose layer (1-1), and the use of ALD technology to alternately deposit an appropriate amount of rare earth element erbium ion and aluminum ion thin film (1-2) with amplifying function. The cladding (2) is made of pure quartz with a low refractive index.

Embodiment 2

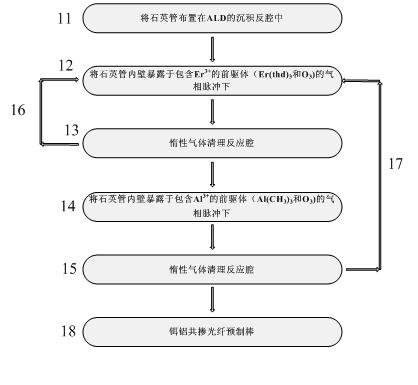

[0024] The manufacturing method of high-concentration erbium-aluminum co-doped amplifying optical fiber based on atomic layer deposition technology is used to make the above-mentioned optical fiber, and its manufacturing steps are as follows:

[0025] 1) First, the cladding layer (2) and pure quartz or doped with a small amount of high refractive index GeO are sequentially deposited on the improved chemical vapor deposition (MCVD) rod making machine by vapor deposition method 2 loose layer, and then place the preformed quartz tube in the deposition reaction chamber of the atomic layer deposition (ALD) technology, and then use the ALD technology to alternately deposit Er 2 o 3 and Al 2 o 3 film until the desired thickness is reached; where Er(thd) 3 and O 3 is used to deposit Er 2 o 3 The gas phase precursor of Al(CH 3 ) 3 and O 3 used to grow Al 2 o 3 film. The entire reaction chamber is heated by radiation, and the temperature is uniform and controlled between 300...

Embodiment 3

[0029] This embodiment is basically the same as Embodiment 2, and the special features are as follows:

[0030] see figure 2 , the manufacturing steps of the high-concentration erbium-aluminum co-doped amplifying fiber based on atomic layer deposition technology are as follows:

[0031] 1) Place the preformed quartz tube in the ALD deposition reaction chamber (11), and use radiation heating to keep the temperature of the entire reaction chamber uniform and controlled between 300-400°C.

[0032] 2) Deposit Er on the inner wall of the quartz tube 2 o 3 Film (12), Er(thd) 3 and O 3 used to grow Er 2 o 3 The thin film, the gas phase pulse of the reactive precursor controlled by the inert gas pulse valve, is introduced into the reaction chamber. During the deposition process, the micro-pulse mode is adopted. This pulse mode can avoid excessive reaction precursors from filling the reaction chamber, but at the same time can provide sufficient dose and reaction time to allow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com