A New Process for Producing Anhydrous Ethanol by Rectification and Pervaporation

A technology of pervaporation and anhydrous ethanol, which is applied in the chemical industry, can solve problems such as high cost, high pollution, and high risk, and achieve the effects of reducing production cost, simple production process, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

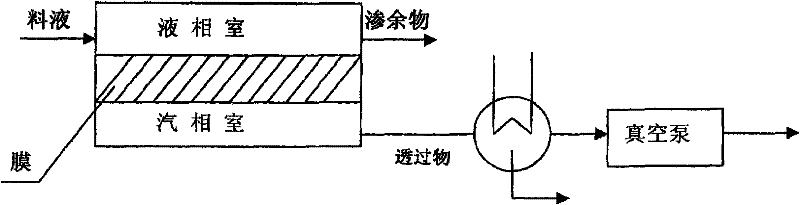

Method used

Image

Examples

Embodiment 1

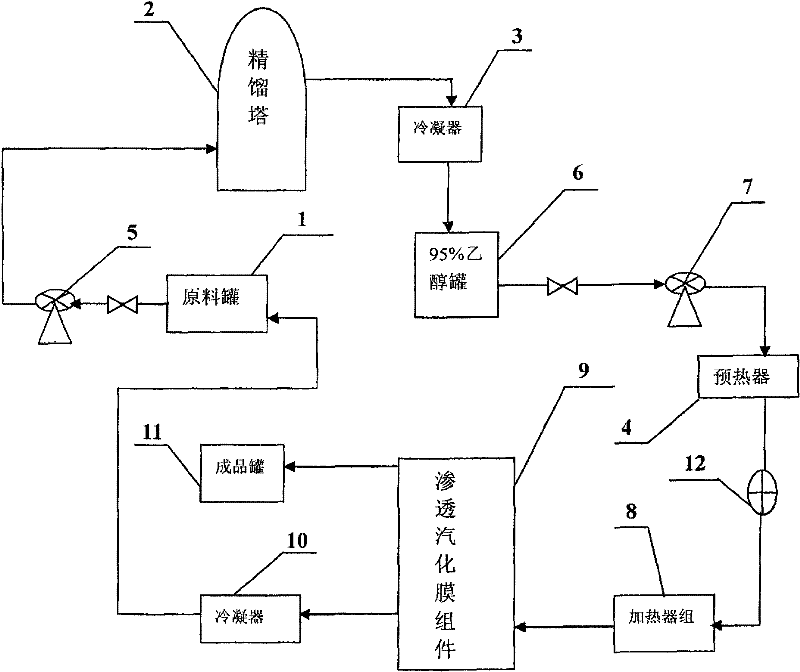

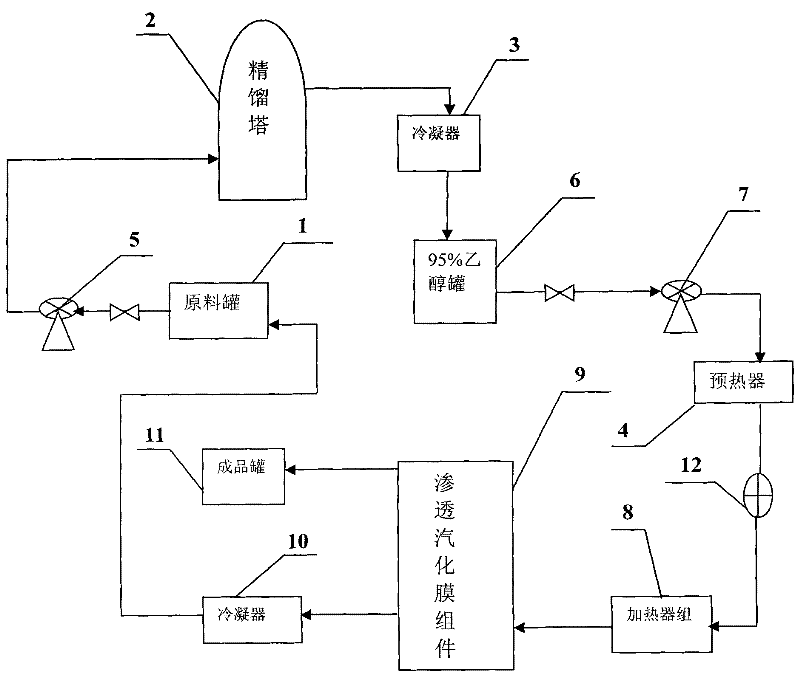

[0016] Example 1: See figure 1 , A new process for the production of absolute ethanol by distillation pervaporation, the steps are as follows:

[0017] (1) The mixed ethanol solution containing 20%-80% water in the raw material tank 1 enters the high-level tank 4 through the A feed pump 5, and then enters the rectification tower 2. The rectification tower has 100 trays, and the temperature of the tower is maintained. 80-90℃, the top temperature of the tower is 78℃, rectification is carried out, and the ethanol produced is condensed by condenser 3, that is, 95% ethanol enters the 95% ethanol tank 6;

[0018] (2) The 95% ethanol solution enters the preheater 4 through the B feed pump 7 to be heated to 80°C-90°C, the flow is controlled to 100-400L / h, and then enters the pervaporation membrane module 9 for separation. Membrane module 9 is composed of ten pervaporation membranes in series, and the membrane area of each membrane is 13.2m 2 , 95% ethanol solution passes through ten perv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com