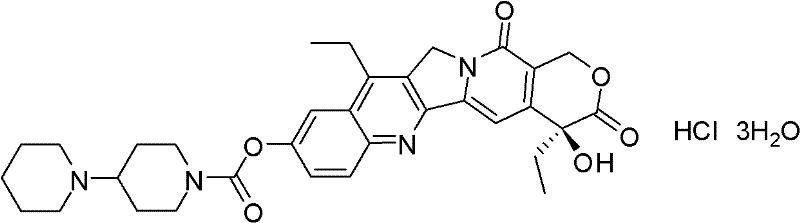

A kind of method for preparing irinotecan hydrochloride

A technology of irinotecan hydrochloride and irinotecan, which is applied in the direction of organic chemistry, can solve the problems affecting the purity and color of the final product, the easy oxidation and discoloration of pyridine, and the easy deterioration of irinotecan, so as to reduce the treatment cost and shorten the reaction time , the effect of not easy to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1) Preparation of irinotecan

[0047] Add 7-ethyl-10-hydroxycamptothecin (10.0g) into dichloromethane (250mL) and stir, add triethylamine (3mL), 4-dimethylaminopyridine (0.5g), 4-piperidine hydrochloride Piperidinecarbonyl chloride (7.0 g), stirred at room temperature overnight (20° C.), and filtered to remove insoluble matter. Wash twice with 10% sodium bicarbonate solution (100 mL), wash twice with saturated sodium chloride solution (100 mL), separate the organic layer, add anhydrous magnesium sulfate (5 g) and dry for 0.5 hour, remove magnesium sulfate by filtration, Chloromethane (50 mL) was used to rinse the filter cake twice, and the organic layers were combined. The solvent was distilled off under reduced pressure at 30°C to obtain solid crude irinotecan (14 g).

[0048] 2) preparation of irinotecan hydrochloride

[0049] Add the irinotecan crude product obtained in step 1) to methanol (100 mL), add a methanol solution of hydrogen chloride (20%) until the pH v...

Embodiment 2

[0053] Add 7-ethyl-10-hydroxycamptothecin (10g) into dichloromethane (250mL) and stir, add triethylamine (25mL) and 4-dimethylaminopyridine (1g), heat to reflux, within 1 hour 4-Piperidinylpiperidinecarbonyl chloride hydrochloride (7 g) was added in portions, and reflux was continued for 60 minutes. Cool and filter to remove insoluble matter. Slowly added to a rapidly stirred petroleum ether solution (2500 mL), a large amount of solid was precipitated, filtered, and dried under reduced pressure to obtain solid irinotecan crude product. The preparation and purification methods of irinotecan hydrochloride were the same as in Example 1, and 13.5 g of refined product was obtained, with a purity of 99.9%, and a simple and complex <0.05% (area normalization method).

Embodiment 3

[0055] 1) Preparation of irinotecan

[0056] Add 7-ethyl-10-hydroxycamptothecin (10g) into dichloromethane (250mL) and stir, add triethylamine (25mL), 4-dimethylaminopyridine (0.5g), 4-piperidinyl hydrochloride Piperidinecarbonyl chloride (10 g), stirred overnight, and after the reaction was complete, insoluble matter was removed by filtration. Wash twice with water (100mL), wash twice with saturated sodium chloride solution (100mL), separate the organic layer, add anhydrous sodium sulfate (5g) to dry for 2 hours, filter to remove magnesium sulfate, dichloromethane (50mL) to rinse and filter Cake twice and combine the organic layers. The solvent was distilled off under reduced pressure at 30°C to obtain 13.2 g of solid irinotecan crude product.

[0057] 2) preparation of irinotecan hydrochloride

[0058] The crude irinotecan hydrochloride obtained in step 1) was added with 12 mol / L hydrochloric acid solution until the pH was 1-2 to obtain about 14.7 g of crude irinotecan hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com