A medical UV-curable water-based conductive pressure-sensitive adhesive

A technology of pressure-sensitive adhesives and ultraviolet light, which is applied in the direction of conductive adhesives, pressure-sensitive films/sheets, adhesives, etc., can solve the problems of insufficient environmental protection in the production process of conductive pressure-sensitive adhesives, limit the application of conductive pressure-sensitive adhesives, etc., and achieve production High efficiency, fast curing speed, and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

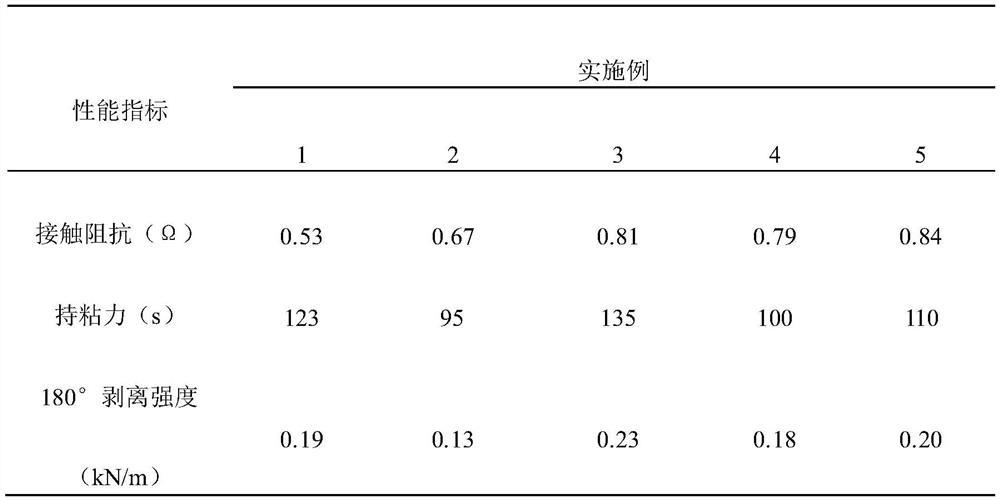

Examples

Embodiment 1

[0015] The chitosan was dissolved in 1% acetic acid solution by volume to obtain an aqueous solution with a mass concentration of 2%. (2) Take 40mL of the above solution and add 30g of acrylic acid, 15g of hydroxypropyl acrylate, 0.7g of crosslinking agent, 0.8g of photoinitiator, 30g of glycerol, and 0.8g of sodium hydroxide, and stir well until all the solids are dissolved. (3) Coating with a paint film applicator to obtain a wet film with a thickness of 2.0 mm. (4) Place the wet film 30 cm below the lamp tube of a cold light type ultraviolet curing machine with a power of 2000W, and take it out after irradiating for 50 seconds to obtain a conductive pressure-sensitive adhesive.

Embodiment 2

[0017] (1) Water-soluble polymer materials such as sodium carboxymethylcellulose are fully dissolved in water overnight to obtain an aqueous solution with a mass concentration of 3%. (2) Take 20 mL of the above solution and add 10 g of acrylic acid, 10 g of hydroxypropyl acrylate, 0.5 g of crosslinking agent, 0.4 g of photoinitiator, 20 g of glycerol, and 0.2 g of sodium hydroxide, and stir until all the solids are dissolved. (3) Coating with a paint film applicator to obtain a wet film with a thickness of 1.0 mm. (4) Place the wet film 20 cm below the lamp tube of a luminescent ultraviolet curing machine with a power of 1000 W, and take it out after irradiating for 80 seconds to obtain a conductive pressure-sensitive adhesive.

Embodiment 3

[0019] (1) The water-soluble polymer material hydroxyethyl cellulose is fully dissolved in water overnight to obtain an aqueous solution with a mass concentration of 5%. (2) Take 30 mL of the above solution and add 15 g of acrylic acid, 20 g of hydroxypropyl acrylate, 0.7 g of crosslinking agent, 0.6 g of photoinitiator, 25 g of glycerol, and 0.4 g of sodium hydroxide, and stir evenly until all the solids are dissolved. (3) Coating with a paint film applicator to obtain a wet film with a thickness of 1.5 mm. (4) Place the wet film at 25 cm below the lamp tube of a cold light type ultraviolet curing machine with a power of 1500W, and take it out after irradiating for 60 seconds to obtain a conductive pressure-sensitive adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com