1,2-propylene glycol antifreezing liquid coolant

A technology of antifreeze coolant and propylene glycol, applied in 1 field, to achieve the effect of good addition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

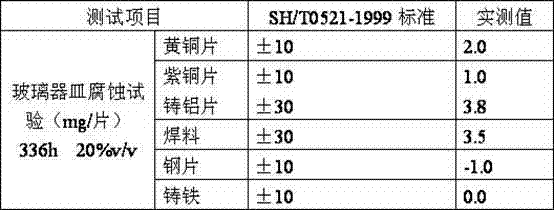

Embodiment 1

[0060] Prepare 1000kg of an antifreeze used in areas where the lowest temperature in the north is below -45°C:

[0061] Put 800kg of 1,2-propanediol into the reaction kettle, add 100kg of water while stirring, keep the temperature in the kettle not exceeding 80°C, then add 3kg of benzotriazole, 3kg of sodium nitrate, 1.4kg of sodium molybdate, benzene Sodium formate 15kg, after stirring and dissolving for 60 minutes, add 12kg of 85Wt.% phosphoric acid, add 18kg of sebacic acid, then adjust pH=7.9~8.5 with potassium hydroxide solid under stirring, then add 1.4kg of hydrolyzed polymaleic anhydride to remove foam Mix 4.5g of agent, 32g of acid green dye, 15g of tartrazine and water (the quality of water is equal to 1000kg minus the sum of all the above-mentioned materials), and then add them to the reaction kettle together to form a light green transparent solution. After passing the inspection, filter through a filter of 0.5-1 μm and then pack.

[0062] The specific parameters ...

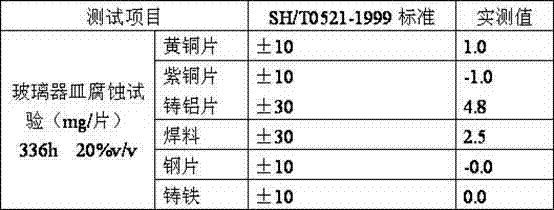

Embodiment 2

[0065] Prepare 1000kg direct use type -30℃ antifreeze coolant:

[0066] Put 600kg of 1,2-propanediol into the reaction kettle, add 200kg of water while stirring, keep the temperature in the kettle not exceeding 80°C, then add 1.9kg of benzotriazole, 2kg of sodium nitrate, 1kg of sodium molybdate, benzene Sodium formate 10kg, after stirring and dissolving for 120 minutes, add 9kg of 85Wt.% phosphoric acid, add 13kg of sebacic acid, then adjust pH=7.9 to 8.5 with potassium hydroxide solid under stirring, then add 1kg of hydrolyzed polymaleic anhydride, cancel Mix 4g of foaming agent, 28g of acid green dye, 14g of tartrazine and water (the quality of water is equal to 1000kg minus the sum of all the above-mentioned materials), and then add them to the reaction kettle together to form a light green transparent solution. After passing the inspection, filter through a filter of 0.5-1 μm and then pack.

[0067] The specific parameters of the glassware corrosion test are as follows: ...

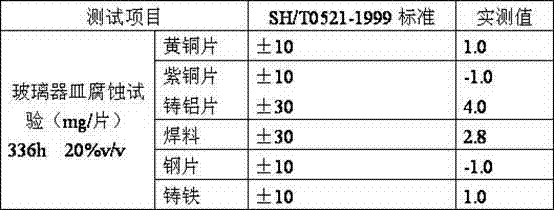

Embodiment 3

[0070] Preparation of 1000kg direct use type - 20 ℃ antifreeze coolant:

[0071] Put 420kg of 1,2-propanediol into the reaction kettle, add 400kg of water while stirring, keep the temperature in the kettle not exceeding 80°C, then add 1.5kg of benzotriazole, 1.5kg of sodium nitrate, and 0.8kg of sodium molybdate , Sodium benzoate 8kg, after stirring and dissolving for 120 minutes, add 6.8kg of 85Wt.% phosphoric acid, add 9kg of sebacic acid, then adjust pH=7.9 to 8.5 with potassium hydroxide solid under stirring, then add hydrolyzed polymaleic anhydride 0.8kg, 4g of defoaming agent, 28g of acid green dye, 14g of tartrazine and water (the quality of water is equal to 1000kg minus the sum of all the above materials) are mixed evenly, and then added to the reaction kettle together, finally forming a light green The transparent solution can be dispensed after being filtered through a 0.5-1μm filter after passing the inspection.

[0072] The specific parameters of the glassware co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap