Graphene graphing methods

A patterning, graphene technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unavailability, graphene pollution, and difficult process, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

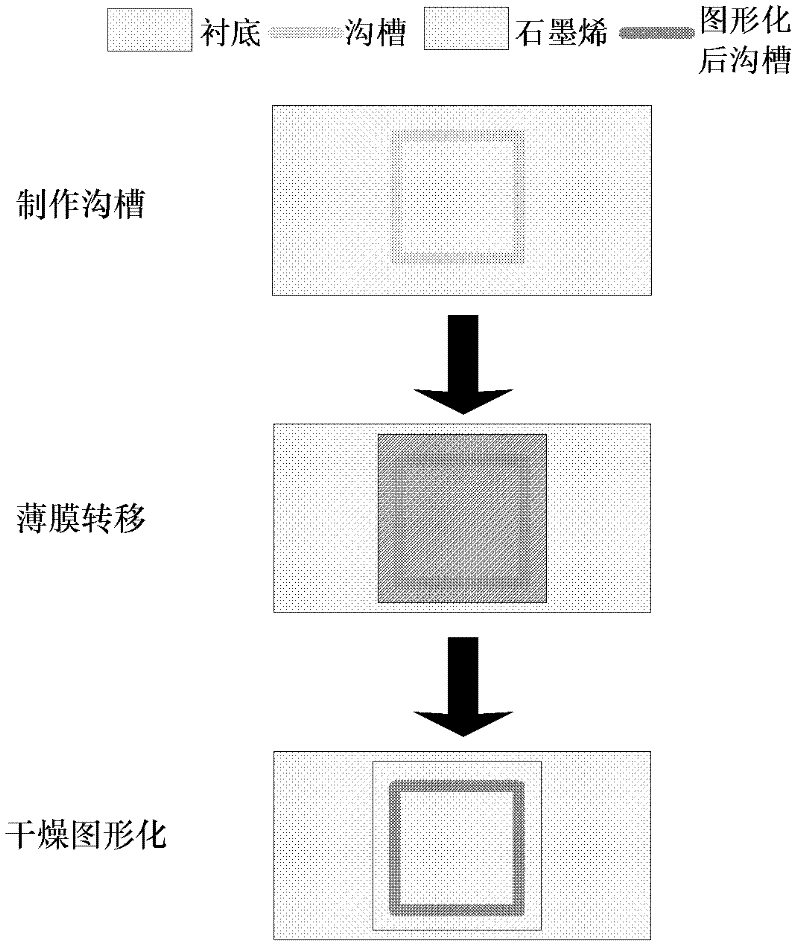

[0032] Square patterning graphene

[0033] 1. Directly use micro-cutting technology to cut a 5×5mm square groove on the ceramic substrate. The groove boundary width is 30um and the depth is 40um. The groove pattern and the top view of the substrate are as follows Figure 4 shown;

[0034] 2. The graphene obtained by mechanical exfoliation is transferred to acetone;

[0035] 3. Take the graphene film directly from the substrate with the pattern in acetone, and the film covers the pattern;

[0036] 4. After drying at 200°C for 15 minutes, patterned graphene can be obtained at the substrate pattern.

Embodiment 2

[0038] Fabrication of composite patterned graphene films

[0039] 1. Photolithography plate and substrate patterns such as Figure 5 As shown, the pattern is a combination of rectangle (0.5×3mm) and square (2×2mm), with a border width of 20um. The silicon substrate is spin-coated with 5um thick glue, then photolithography, developed and then dried, using deep reactive ion etching. Etch a trench of 30um on the silicon substrate, remove glue, clean and dry after etching;

[0040] 2. Large-area high-quality graphene prepared by CVD method on Cu foil was transferred to deionized water;

[0041] 3. Use the trench substrate to fish the graphene film in the solution, and the film covers the trench;

[0042] 4. After drying at 40°C for 30 minutes, patterned graphene can be obtained at the substrate pattern, and then metal devices can be made on the square area to make striped graphene devices (such as Figure 5 shown).

Embodiment 3

[0044] Fabrication of graphene with six-electrode polygons

[0045] 1. Make a trench substrate, the photolithographic pattern is as follows Figure 6 Shown, technological process is identical with the technological process in step 1 among the embodiment 2;

[0046] 2. Steps 2, 3, and 4 are the same as steps 2, 3, and 4 in Example 2.

[0047] The method for patterning graphene provided by the invention is mainly characterized in that:

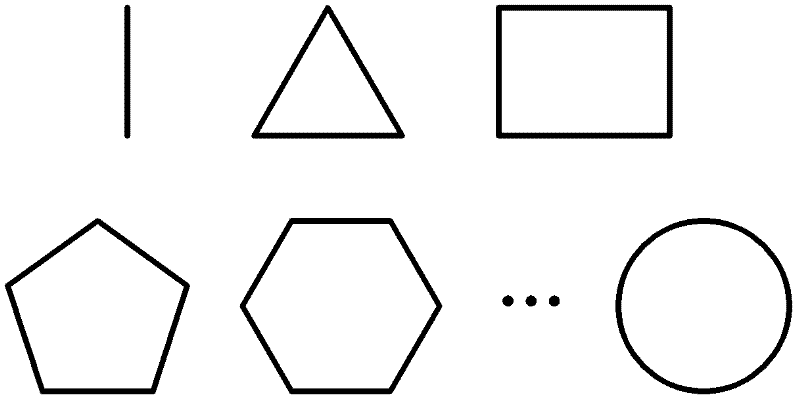

[0048] 1. Use the method of deep reactive ion etching, micro-cutting technology or wet etching in the micro-technology processing process to produce the required groove pattern on the substrate. The pattern can be linear, circular, rectangular, polygonal, or comb-shaped. etc. and combinations thereof;

[0049] 2. The substrate can be silicon wafer, silicon oxide wafer, ceramics, glass, etc.;

[0050] 3. The graphic boundary is a groove with a certain width and depth, and the aspect ratio is > 1.1;

[0051] 3. Different trench etching method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com