Ru-Pd-Co-coated Titanium Electrode with Sn-Sb Interlayer

An intermediate layer and titanium electrode technology, applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems of harsh preparation conditions, short service life, short service life of electrodes, etc., and achieve improved electrochemical performance, increased service life, high The effect of oxygen evolution potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

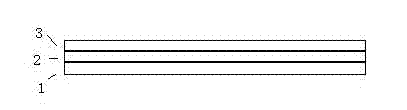

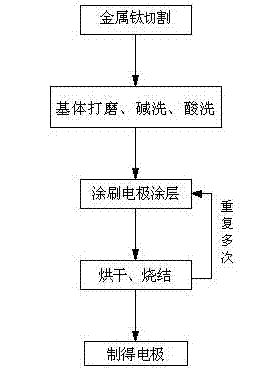

[0014] combine figure 1 , the ruthenium-palladium-cobalt-coated titanium electrode containing the tin-antimony intermediate layer of the present invention, the surface of the titanium plate main body 1 has several layers of tin-antimony oxide coatings 2 as the intermediate layer, and the surface of the intermediate layer has several layers of ruthenium-palladium-cobalt oxide coatings 3 As the surface layer; by adding a certain proportion of palladium (Pd, PdO) cobalt (Co, CoO, Co2O3) elements to RuO2 as the electrode surface layer, the electrocatalytic performance and service life of the electrode are improved; by adding tin antimony oxide intermediate layer, Further improve the electrocatalytic performance and service life of the electrode; through various testing methods and using the electrode in the water treatment process, it is proved that the electrode of the utility...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com