Ultraviolet-aging-resistant polyphenylene sulfide fibers and preparation method thereof

A polyphenylene sulfide fiber, anti-ultraviolet aging technology, applied in fiber treatment, stretch spinning, artificial filament physical therapy, etc., can solve the problems of poor anti-ultraviolet aging performance of PPS fiber, achieve stable performance, reduce Possibility of degradation, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

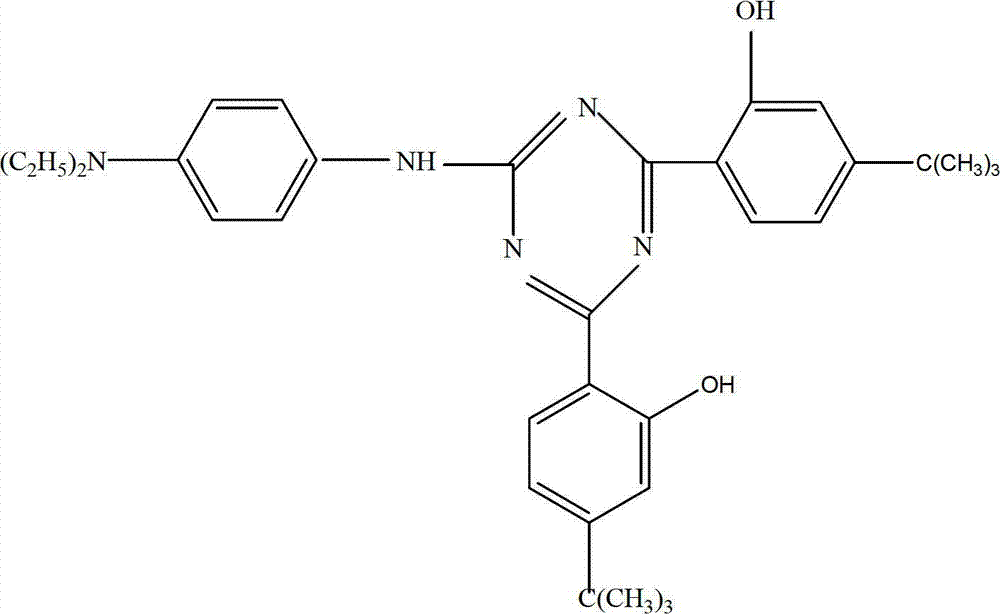

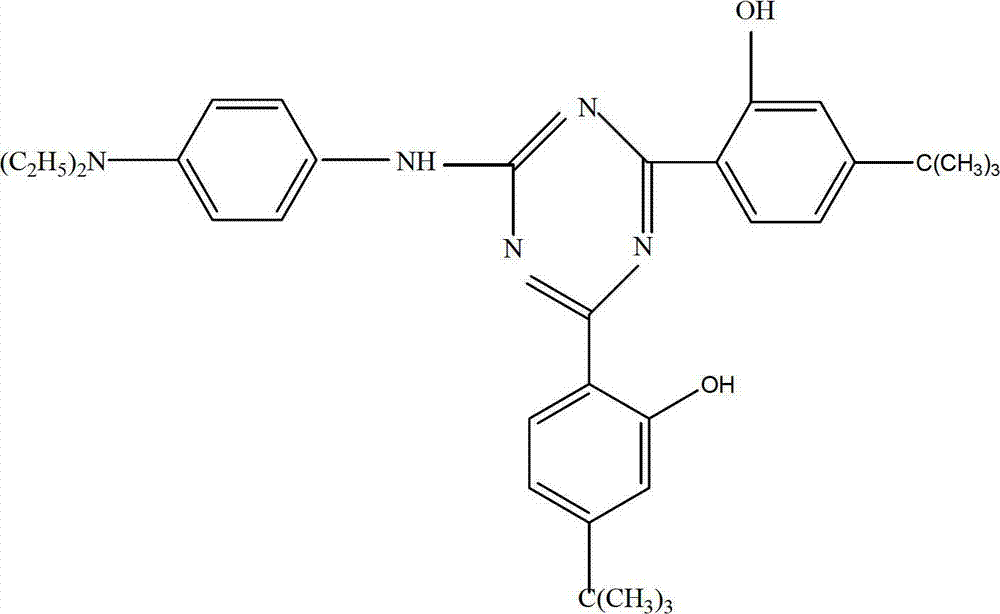

[0050] (1) Dissolve 60 parts of trichloro-s-triazine in dichloromethane, drop 100 parts of and 50 parts of AlCl 3 Into the mixed solution, keep stirring under the protection of N2, keep the temperature at about 25 ° C, after 2 hours of reaction, pour ice water to cool, AlCl 3 Reacts with water to form Al(OH) 3 , filter the suspension to remove aluminum hydroxide, then add 55 parts of in N 2 Stirring continuously under the protection of , keeping the temperature at about 25 ° C, after 4 hours of reaction, remove the raw materials that did not participate in the reaction in the solvent, and then slowly evaporate the solvent to obtain 2-(4-N,N-diethylaminophenyl) Amino-4,6 bis(4-tert-butyl-2-hydroxyphenyl)-s-triazine;

[0051] Its molecular structure is

[0052]

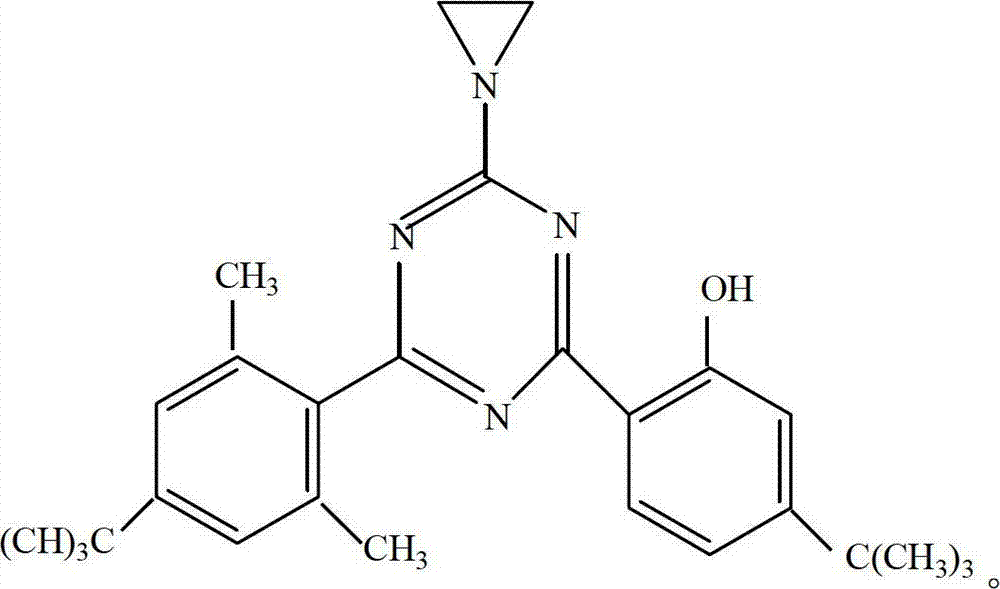

[0053] (2) Dissolve 60 parts of trichloro-s-triazine in dichloromethane, drop 50 parts of 52 copies and 50 parts of AlCl 3 into the mixture, in N 2 Stirring continuously under the protection, keeping the...

Embodiment 2

[0063] (1) Dissolve 65 parts of trichloro-s-triazine in dichloromethane, drop 110 parts of and 55 parts of AlCl 3 into the mixture, in N 2 Stirring continuously under the protection, keeping the temperature at about 25°C, after reacting for 2 hours, pour ice water to cool, AlCl 3 Reacts with water to form Al(OH) 3 , filter the suspension to remove aluminum hydroxide, then add 60 parts of in N 2 Stir continuously under the protection of the hood, keep the temperature at about 25°C, after 4 hours of reaction, remove the raw materials that have not participated in the reaction in the solvent, and then slowly evaporate the solvent to obtain 2-(4-N,N-diethylaminophenyl) Amino-4,6 bis(4-tert-butyl-2-hydroxyphenyl)-s-triazine;

[0064] Its molecular structure is

[0065]

[0066] (2) Dissolve 65 parts of trichloro-s-triazine in dichloromethane, drop 55 parts of 56 copies and 55 parts of AlCl 3 into the mixture, in N 2 Stirring continuously under the protection, keepi...

Embodiment 3

[0076] (1) Dissolve 62 parts of trichloro-s-triazine in dichloromethane, drop 106 parts of and 52 parts of AlCl 3 into the mixture, in N 2 Stirring continuously under the protection, keeping the temperature at about 25°C, after reacting for 2 hours, pour ice water to cool, AlCl 3 Reacts with water to form Al(OH) 3 , filter the suspension to remove aluminum hydroxide, then add 56 parts of in N 2 Stirring continuously under the protection of , keeping the temperature at about 25 ° C, after 4 hours of reaction, remove the raw materials that did not participate in the reaction in the solvent, and then slowly evaporate the solvent to obtain 2-(4-N,N-diethylaminophenyl) Amino-4,6 bis(4-tert-butyl-2-hydroxyphenyl)-s-triazine;

[0077] Its molecular structure is

[0078]

[0079] (2) Dissolve 62 parts of trichloro-s-triazine in dichloromethane, drop 51 parts of 53 copies and 51 parts of AlCl 3 into the mixture, in N 2 Stirring continuously under the protection, keepin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com