Method for Determination of Component Content in Iron Oxide Powder Using X-ray Fluorescent Tablet Method

A technology of iron oxide powder and component content, which is applied in the field of chemical analysis, can solve problems affecting the accuracy of analysis results, complex operation, easy introduction of impurities, etc., and achieve good accuracy and reproducibility, simple operation, and broaden the analysis range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

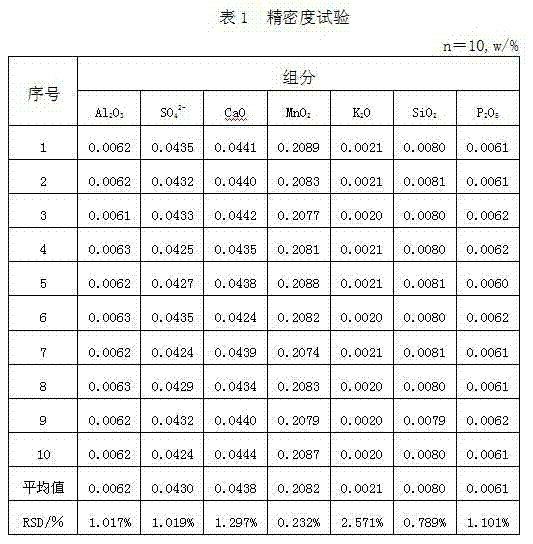

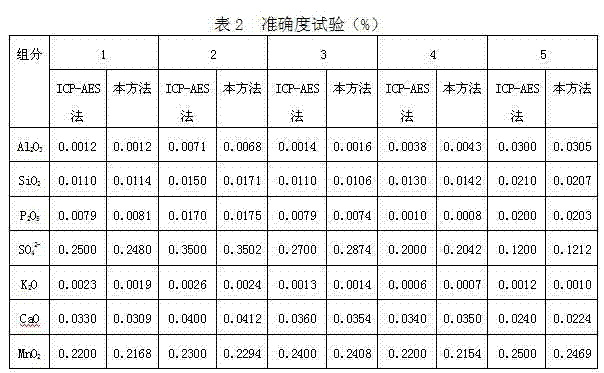

[0015] The method for determining the content of components in iron oxide powder using the X-ray fluorescent tablet method is determined by an X-ray fluorescence spectrometer. Firstly, the spectral lines with high intensity and signal-to-background ratio are selected as the analysis curves, and the analysis lines, crystals, detectors, peak 2θ angles and measurement time of the seven elements of aluminum, silicon, phosphorus, sulfur, potassium, calcium, and manganese They are: aluminum Al-Ka PET PC 144.784°30s, phosphorus P-Ka Ge PC 141.096°20s, sulfur S-Ka Ge PC 110.718°20s, potassium K-Ka LiF1 PC 136.692°30s, calcium Ca-Ka LiF1 PC 113.118 °20s, manganese Mn-Ka LiF1 SC, set analysis conditions: light tube voltage 50KV, current 50mA, no filter, no attenuator. Then prepare iron oxide powder standard sample one and iron oxide powder standard sample two, wherein the method for adding a small amount of national standard slag samples in iron oxide powder standard sample one has prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com