Image display device and organic electroluminescence element

An image display device and luminescent technology, applied in electroluminescent light sources, electrical components, electric light sources, etc., can solve the problems of low luminous efficiency, lack of practicability, and difficulty in making films, etc., and achieve the effect of excellent element characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0127] Hereinafter, the present invention will be described more specifically with reference to production examples, examples, and comparative examples, but the present invention is not limited to the following examples. Measuring devices for various physical properties in Examples are as follows.

[0128] [1] Molecular weight

[0129] Apparatus: GPC measurement apparatus at room temperature (SSC-7200, manufactured by Senshiyu Ikegaku Co., Ltd.)

[0130] Eluent: DMF

[0131] [2] TG / DTA (differential thermogravimetry simultaneous measurement device)

[0132] Device: Thermoplus TG8120 (Rigaku Denki Co., Ltd.)

[0133] [3]FT-IR

[0134] Device: NICOLET 5700 (Thermo ELECTRON CORPORATION)

[0135] [4] Film thickness

[0136] Measuring device: Micrometer (manufactured by Santop Co., Ltd.)

[0137] [5]UV-Vis spectrum

[0138] Device: UV-VIS-NIR SCANNING SPECTROPHOTOMETER (self-recording spectrophotometer) (manufactured by Shimadzu Corporation)

[0139] [6] X-ray diffraction ...

manufacture example 1

[0143] [Manufacturing example 1] Synthesis of TDA / 1,3-BAPB polyamic acid and polyimide, and production of polyimide film

[0144] [chemical 8]

[0145]

[0146] 1.95 g (7.0 mmol) of 1,3-BAPB and 16.0 g of DMAc were added to a 50 mL four-neck reaction flask equipped with a stirrer installed in a water bath at 25° C., and 1,3-BAPB was dissolved in DMAc. Next, stirring this solution, it added slowly, dissolving 2.10 g (7.0 mmol) of TDA. Furthermore, it stirred at 26 degreeC for 24 hours, and superposition reaction was performed, and the polyamic-acid solution of 20 mass % of solid content was obtained.

[0147] After casting the solution on a glass plate of 75mm×100mm, put it in a decompression dryer (pressure 100Pa) and perform 80°C / 4 hours, 140°C / 1.5 hours, 190°C / 1.5 hours and 240°C / 2 Hours of firing in stages. Then, the film-coated glass substrate was immersed in a hot water bath at 80° C. for 1 hour, and the film was peeled off from the glass plate. The peeled film was...

Embodiment 1

[0176] Using the TDA / 1,3-BAPB polyimide film made in Manufacturing Example 1 as a substrate, the ITO made in the anodic film-forming process of Comparative Example 1 (b) was heat-treated under the following conditions. In addition, An organic EL element was fabricated under the same conditions as in Comparative Example 1.

[0177]

[0178] Put the polyimide substrate with the amorphous ITO film made in the anode film-forming process into the furnace core tube that has formed a vacuum (continuous exhaust with a rotary pump, pressure 4.0Pa), and perform heat treatment according to the following conditions, so that Amorphous ITO is crystallized.

[0179] Room temperature~200℃(2.3℃ / min)

[0180] 200℃~250℃(1.3℃ / minute)

[0181] 250°C (hold for 120 minutes)

[0182] 250℃~room temperature (8 hours, natural cooling)

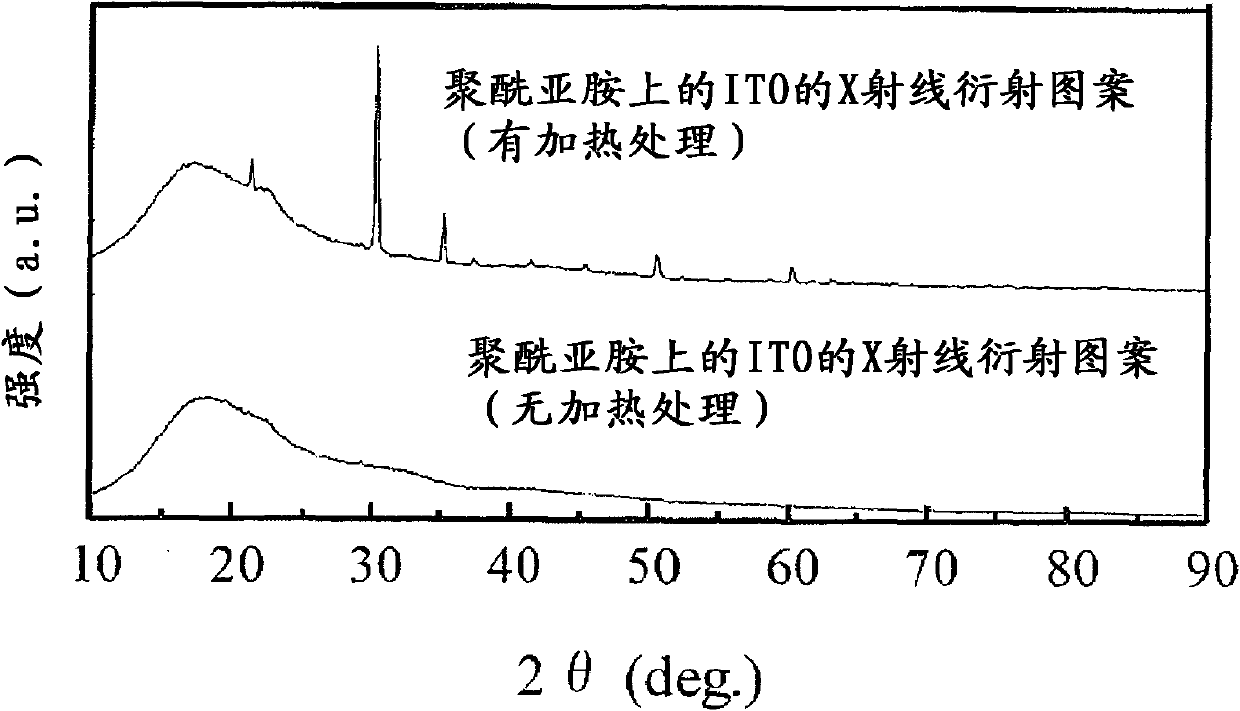

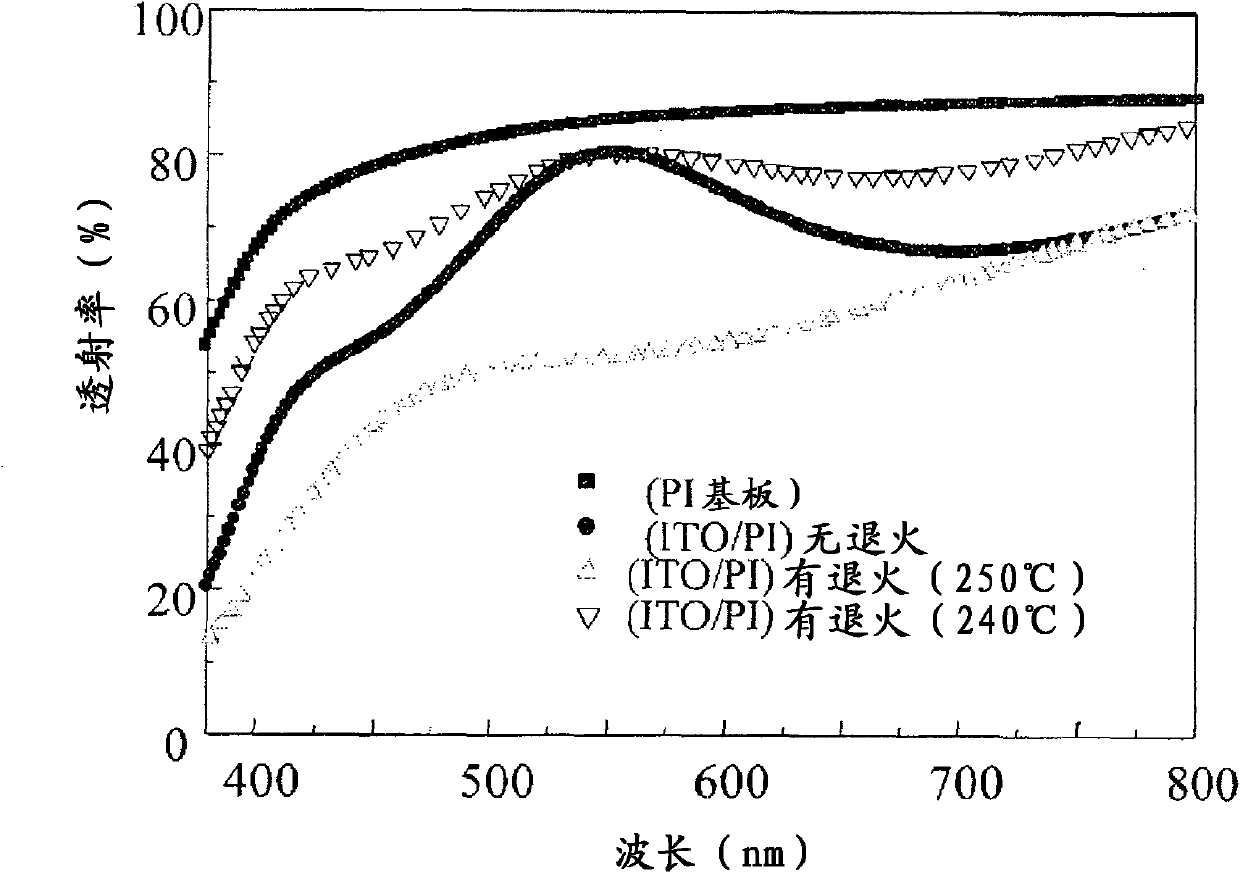

[0183] For the ITO films produced in the above-mentioned Example 1 and Comparative Example 1, crystallization was determined by X-ray diffraction (CuKα), and light...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com