Universal Partition Wall Vibration Recovery Process and Device for Volatile Organic Compounds

A volatile organic compound, general-purpose technology, used in the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., can solve problems such as difficulties, and achieve the effect of reducing the amount of coolant, high purity, and overcoming separation difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The flow rate of a pharmaceutical factory is 2000-3000NM 3 / hour Dimethylformamide (DMF) mixed tail gas, DMF content 5% (volume ratio).

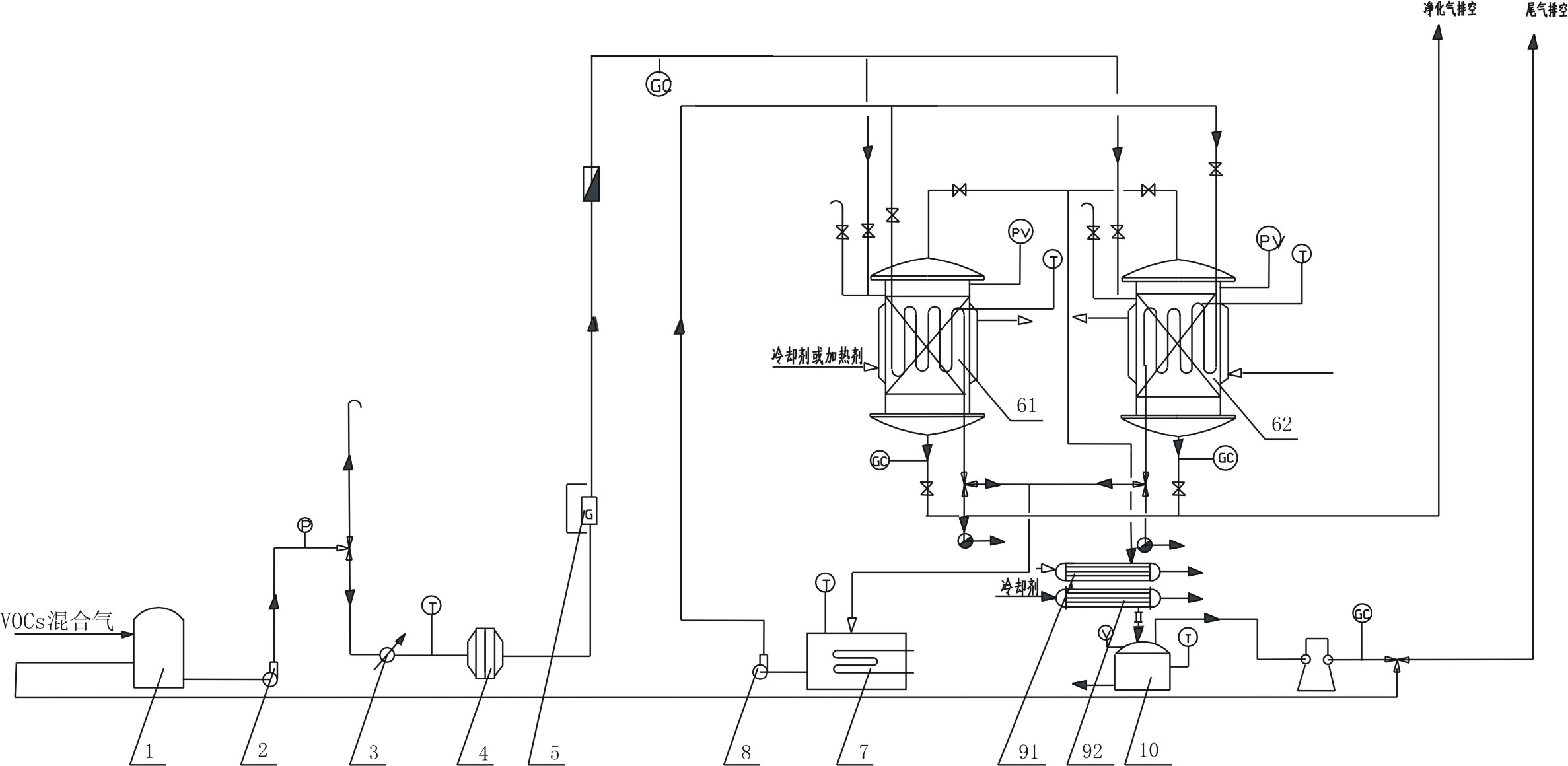

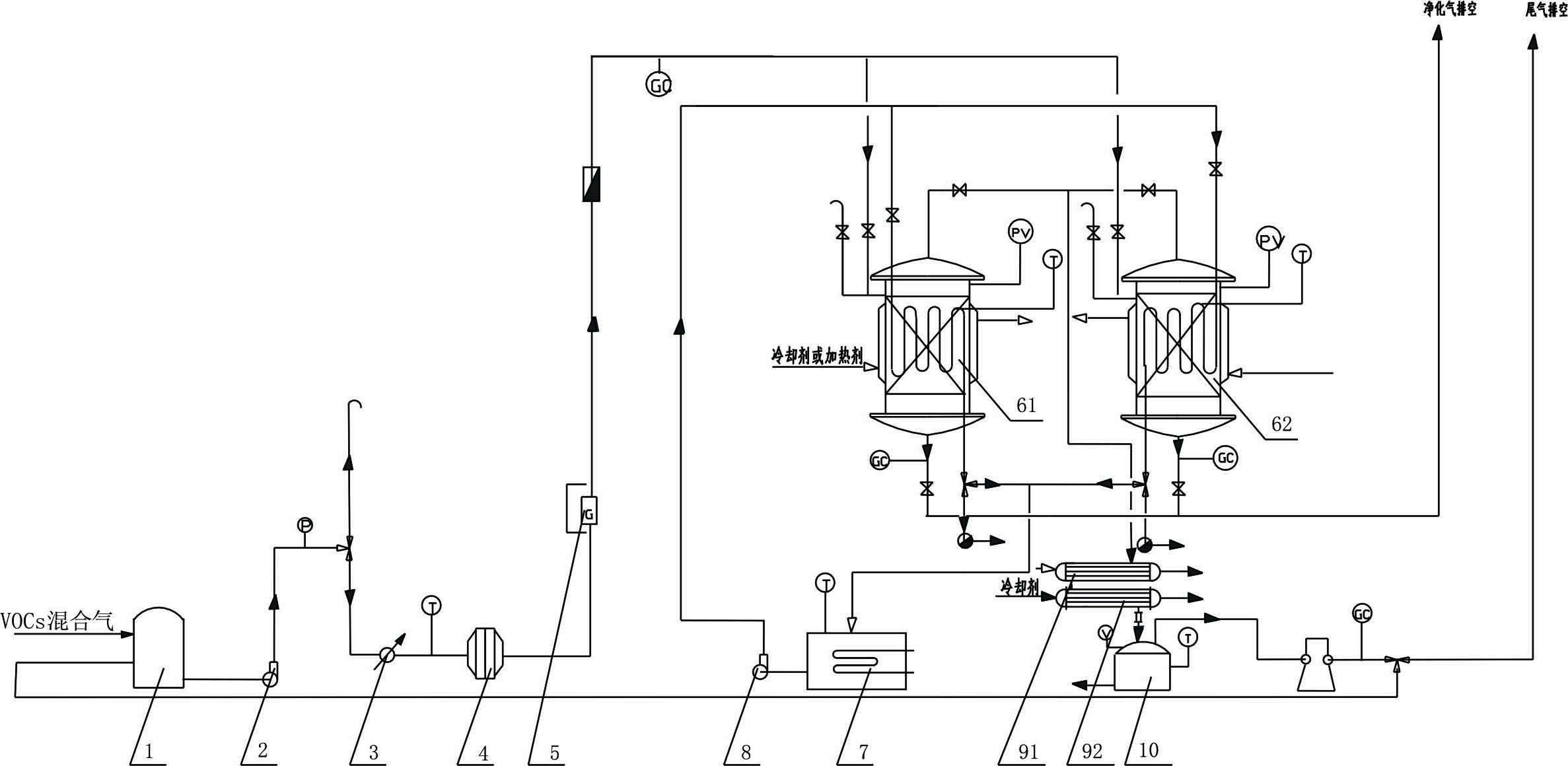

[0037] according to figure 1Connect equipment, pipelines, fittings and control instruments. The adsorption-desorption device 61 and the adsorption-desorption device 62 are filled with solid adsorbent ACF, and after the DMF mixed tail gas is dried and filtered for pretreatment, the DMF content of 5% (volume ratio) is determined by gas chromatography, and flows into the buffer tank 1 (the function is Concentration and flow rate), through the high-pressure blower 2, through the cooler 3 and filter 4, at a flow rate of 0.2-0.8m / s (to the diameter of the tank or tower), through the flame arrester 5, flow from top to bottom, and enter The adsorption-desorption device 61 adsorbs VOCs in the exhaust gas, and at the same time, the outer jacket heat exchanger of the adsorption-desorption device 61 and the tube heat exchanger inside the devic...

Embodiment 2

[0043] Except for the following operations, the rest are the same as in Embodiment 1, that is, in the adsorption operation stage, the coolant introduced into the outer jacket heat exchanger of the adsorption-desorption device 61 is changed to cooling water. During the desorption operation stage, water vapor at 150°C is used to heat the partition wall, which is respectively introduced into the outer jacket heat exchanger of the adsorption-desorption device 61 and the tube heat exchanger inside the device; the temperature of the solid adsorbent is gradually raised to maintain the set temperature Complete the desorption process at 110°C and maintain a vacuum of 0.07MPa; use cooling water as the coolant for cooling the condenser 91 .

Embodiment 3

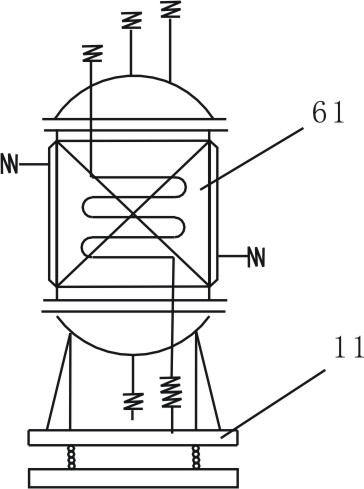

[0045] Except for the following operations, the rest are the same as in Example 1, a vibrator is arranged under the adsorption-desorption device, granular activated carbon is filled in the tank, and the vibration frequency is 150 minutes during the adsorption operation. During the adsorption operation stage, the coolant introduced into the outer jacket heat exchanger of the adsorption-desorption device 61 is changed to cooling water. In the desorption operation stage, water vapor at 150°C is used for heating the partition wall, which is respectively introduced into the outer jacket heat exchanger of the adsorption-desorption device 61 and the tube heat exchanger inside the device; the temperature of the adsorbent is gradually raised to maintain the set temperature of 110 °C. °C to complete the desorption process and maintain a vacuum of 0.07 MPa; use cooling water as the coolant for cooling the condenser 91.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com