Simultaneous flue gas desulfurization and denitrification system and method based on hydrogen peroxide

A hydrogen peroxide, desulfurization and denitrification technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as catalyst blockage, wear, and catalyst poisoning, and achieve low energy consumption, low investment costs, and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

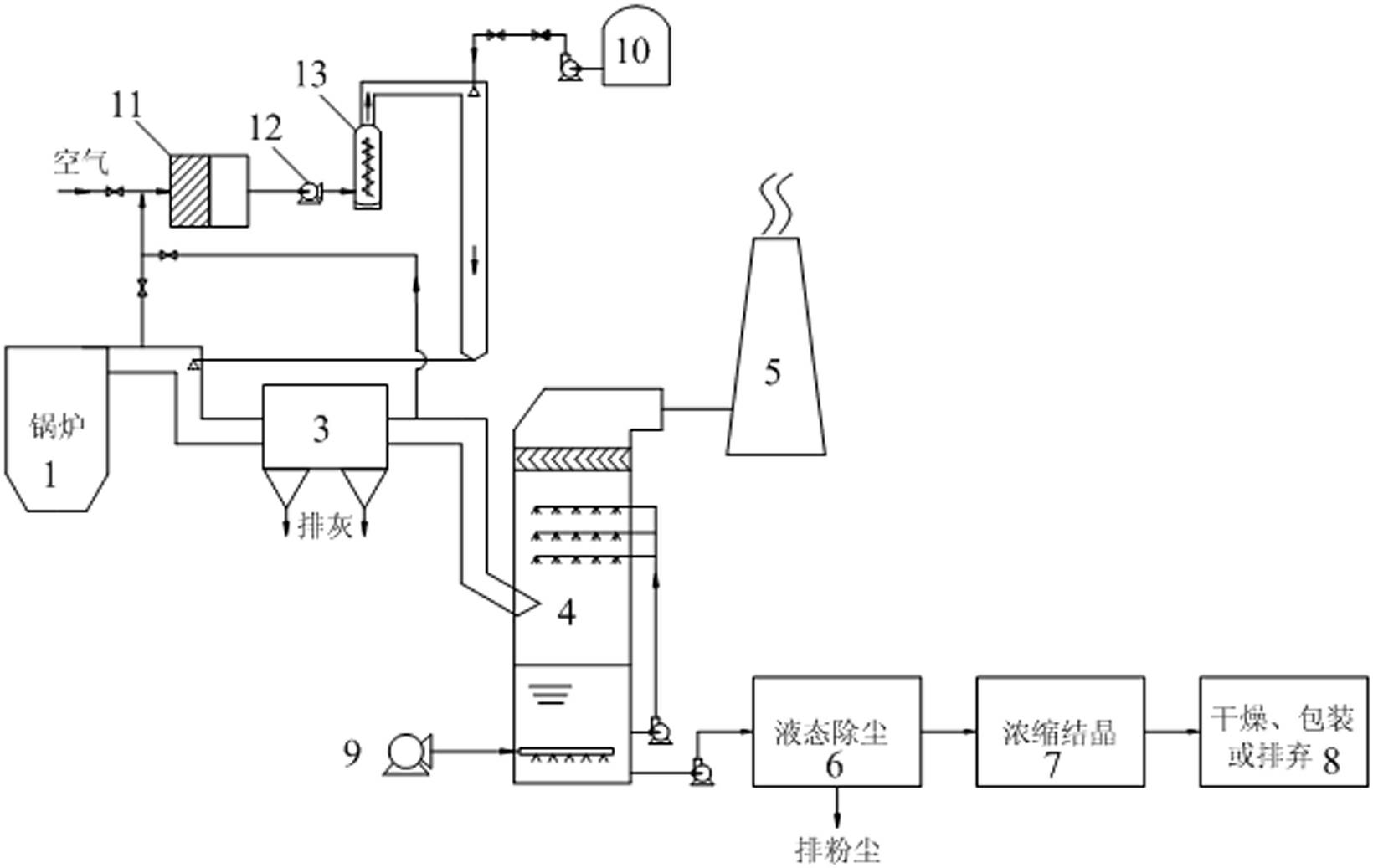

[0028] like figure 2 As shown, in this embodiment, the flue gas generating device 1 is a boiler, and the hydrogen peroxide vaporization system includes a filter device 11, a fan 12, a heating device 13 and a hydrogen peroxide storage tank 10; the filter device 11 One end of each is connected with the first pipeline, the second pipeline and the third pipeline, and the other end is connected with the fan 12; the other end of the fan 12 is connected with the heating device 13, and the other end of the heating device 13 is connected with the fifth pipeline , the fifth pipeline is connected to one end of the fourth pipeline, and the other end of the fourth pipeline is connected to a gas distribution device; the fifth pipeline is provided with an atomizing nozzle, and the atomizing nozzle is connected to a fourth A control valve, the fourth control valve is connected with a one-way valve, the one-way valve is connected with a supply pump, and the supply pump is connected with a hyd...

Embodiment 2

[0032] like image 3 As shown, the difference from Example 1 is that a reaction chamber 2 is provided on the flue between the gas distribution device and the dust collector 3, such as Figure 4 and 5 As shown, the reaction chamber includes a first hollow cylinder 14 and a second hollow cylinder 15 sleeved in the first hollow cylinder 14, and the length of the second hollow cylinder 15 is shorter than that of the first hollow cylinder Body length 14, one end of the first hollow cylinder 14 and one end of the second hollow cylinder 15 are respectively connected to the two ends of a hollow circular platform side wall 16, the other end of the first hollow cylinder 14 and the second hollow cylinder The other ends of the two hollow cylinders 15 are respectively connected to the two ends of the side wall of another hollow circular platform 17 .

[0033] When using the system of Example 2 to carry out desulfurization and denitrification operations, wherein the moles of hydrogen pero...

Embodiment 3

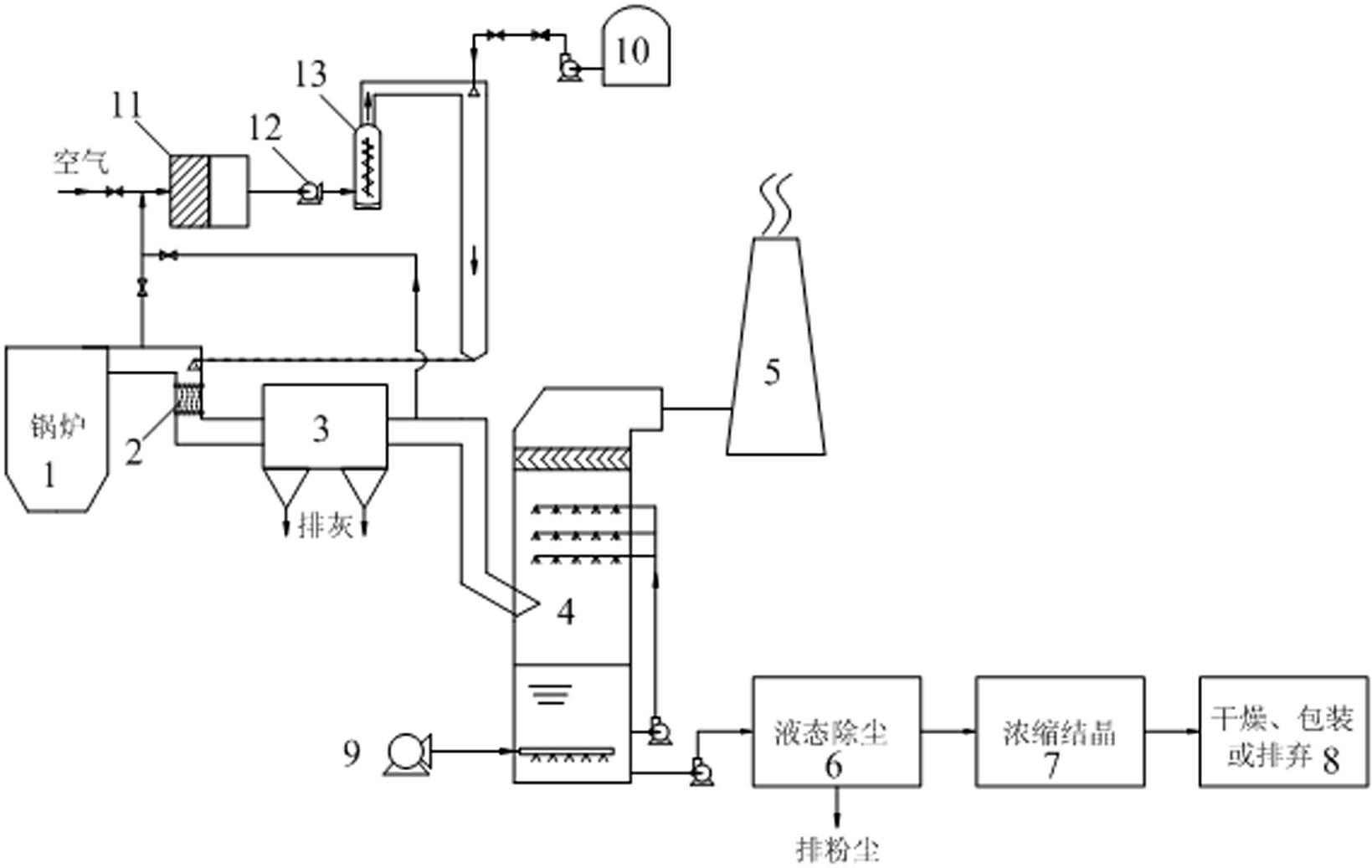

[0036] like Figure 6 As shown, the difference from Example 1 is that the gas distribution device is arranged on the flue between the dust collector 3 and the absorption tower 4 .

[0037] When using the system of Example 3 for desulfurization and denitrification operations, wherein the moles of hydrogen peroxide gas injection are 1.8 times the moles of nitric oxide, and the oxidation time is 0.5 seconds, in the present embodiment, the first control valve and The third control valve is closed, and the second control valve is opened, so that the flue gas in the flue between the dust collector and the absorption tower enters the heating device, and the temperature of the flue gas in the flue between the dust collector and the absorption tower is 110°C. The temperature of the gas coming out of the heating device is 250°C. The detection instrument used for nitrogen oxides and sulfur dioxide in the flue gas is: NOVA2000, and the NOx in the flue gas generated by the flue gas generat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Denitrification efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com