Catalyst regeneration unit for methanol to olefins

A technology of methanol to olefins, regeneration device, applied in catalyst regeneration/reactivation, molecular sieve catalyst, physical/chemical process catalyst, etc., can solve the problem that only one can be provided.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

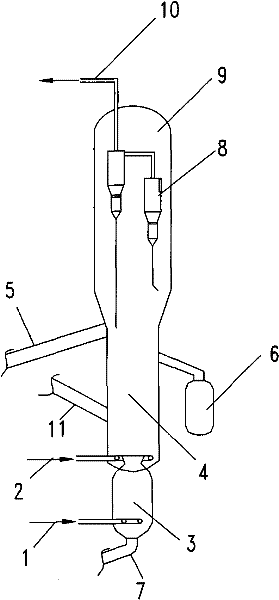

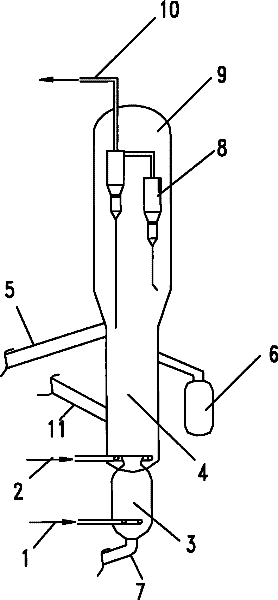

[0019] in such as figure 1 In the small regeneration device shown, the regeneration temperature is controlled by an external full-return mixing heat extractor. The gas-solid cyclone separator adopts two stages. The regeneration temperature in the first regeneration zone is 630°C, and the regeneration temperature in the second regeneration zone is 670°C. Compressed air is used as the regeneration medium, and SAPO-34 molecular sieve catalyst is used. The bed density of the first regeneration zone is 385 kg / m3, and the bed density of the second regeneration zone is 427 kg / m3. The bottom of the regeneration zone is connected. The catalyst in the first regeneration zone enters the second regeneration zone through the pipeline at the bottom. The first regeneration inclined pipe, the second regeneration inclined pipe and the inclined pipe to be raw are all equipped with catalyst sampling equipment. The catalyst samples taken out are Infrared carbon and sulfur analyzer measures the am...

Embodiment 2

[0021] in such as figure 1 In the small-scale regeneration device shown, the regeneration temperature is controlled by an external full-return mixing heat extractor. The gas-solid cyclone separator adopts three stages. The regeneration temperature in the first regeneration zone is 650°C, and the regeneration temperature in the second regeneration zone is 685°C. Compressed air is used as the regeneration medium, and SAPO-34 molecular sieve catalyst is used. The bed density of the first regeneration zone is 402 kg / m3, and the bed density of the second regeneration zone is 439 kg / m3. The bottom of the regeneration zone is connected. The catalyst in the first regeneration zone enters the second regeneration zone through the pipeline at the bottom. The first regeneration inclined pipe, the second regeneration inclined pipe and the inclined pipe to be raw are all equipped with catalyst sampling equipment. The catalyst samples taken out are Infrared carbon and sulfur analyzer measure...

Embodiment 3

[0023] in such as figure 1In the small-scale regeneration device shown, the regeneration temperature is controlled by an external full-return mixing heat extractor. The gas-solid cyclone separator adopts the first stage, and the regeneration temperature in the first regeneration zone is 618°C, and the regeneration temperature in the second regeneration zone is 650°C. Compressed air is used as the regeneration medium, and SAPO-34 molecular sieve catalyst is used. The bed density of the first regeneration zone is 395 kg / m3, and the bed density of the second regeneration zone is 454 kg / m3. The bottom of the regeneration zone is connected. The catalyst in the first regeneration zone enters the second regeneration zone through the pipeline at the bottom. The first regeneration inclined pipe, the second regeneration inclined pipe and the inclined pipe to be raw are all equipped with catalyst sampling equipment. The catalyst samples taken out are Infrared carbon and sulfur analyzer m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com