A kind of preparation method of nanocrystalline rare earth permanent magnetic alloy powder

A rare earth permanent magnet and alloy powder technology, which is applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of poor uniformity, coarse grain size, uneven internal structure of materials, etc., and achieve excellent permanent magnetic performance, excellent Effect of Magnetic Properties, Uniform Microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

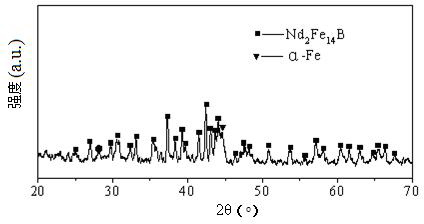

Embodiment 1

[0022] A method for manufacturing nanocrystalline rare earth permanent magnetic alloy powder, comprising:

[0023] (1) Weigh the alloy raw material according to the design ratio, so that its composition is Nd 13.2 Fe 80.8 B 6 ,

[0024] (2) Cast the above ingredients into alloy ingots after high-frequency induction melting under vacuum conditions,

[0025] (3) Vacuum anneal the alloy ingot at 1050°C for 10h,

[0026] (4) Inductively melt the alloy ingot under vacuum conditions, the melting temperature is 1380°C,

[0027] (5) The molten alloy flows through the quartz nozzle onto the water-cooled molybdenum wheel that rotates rapidly at a speed of 25m / s, and is rapidly solidified into strips with a thickness of 20-40μm.

[0028] (6) Break the strip into a powder of less than 50 mesh in the protective atmosphere of argon,

[0029] (7) The above powder is subjected to microwave heat treatment under vacuum condition, the treatment temperature is 630° C., and the time is 5 min...

Embodiment 2

[0032] The other operations of this embodiment are the same as in Embodiment 1, the difference is that the composition of the alloy is Nd 12.2 Fe 80.8 B 6 Ga 1 .

[0033] The nanocrystalline rare earth permanent magnet alloy powder obtained in this example is tested, and the magnetic energy product (BH) m reaches 145kJ / m 3 .

Embodiment 3

[0035] The other operations of this embodiment are the same as in Embodiment 1, the difference is that the composition of the alloy is Nd 9.5 Fe 85 B 5.5 .

[0036] The nanocrystalline rare earth permanent magnet alloy powder obtained in this example is tested, and the magnetic energy product (BH) m reaches 132kJ / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com