A kind of method utilizing ice-water mixture to dilute concentrated sulfuric acid in preparing graphite oxide

A technology of ice-water mixture and concentrated sulfuric acid, applied in the field of diluting concentrated sulfuric acid with ice-water mixture in the preparation of graphite oxide, can solve the problems of difficult control system temperature, long reaction time, high equipment requirements, etc., achieve good thermal conductivity and low equipment requirements , The process is simple and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

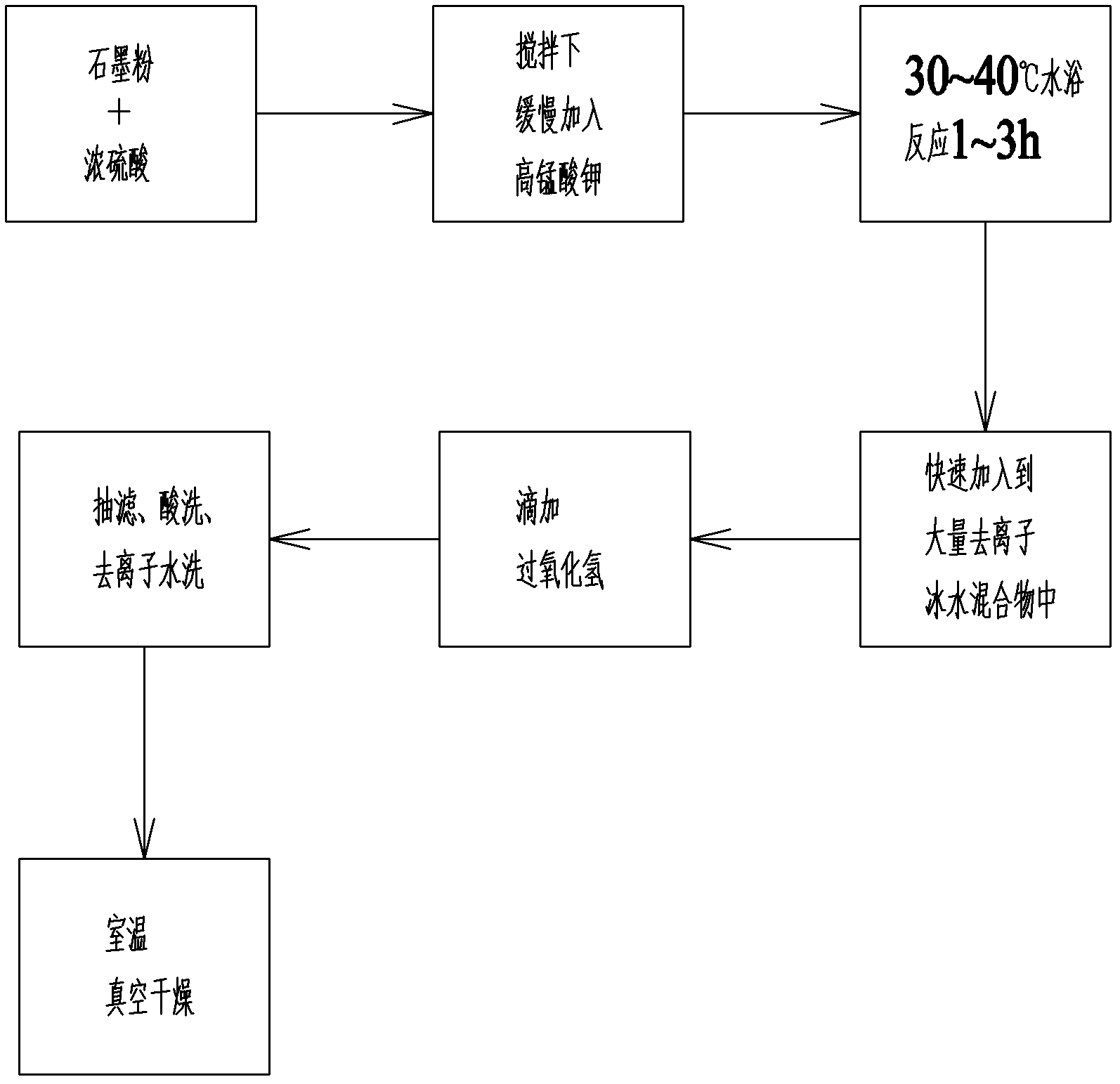

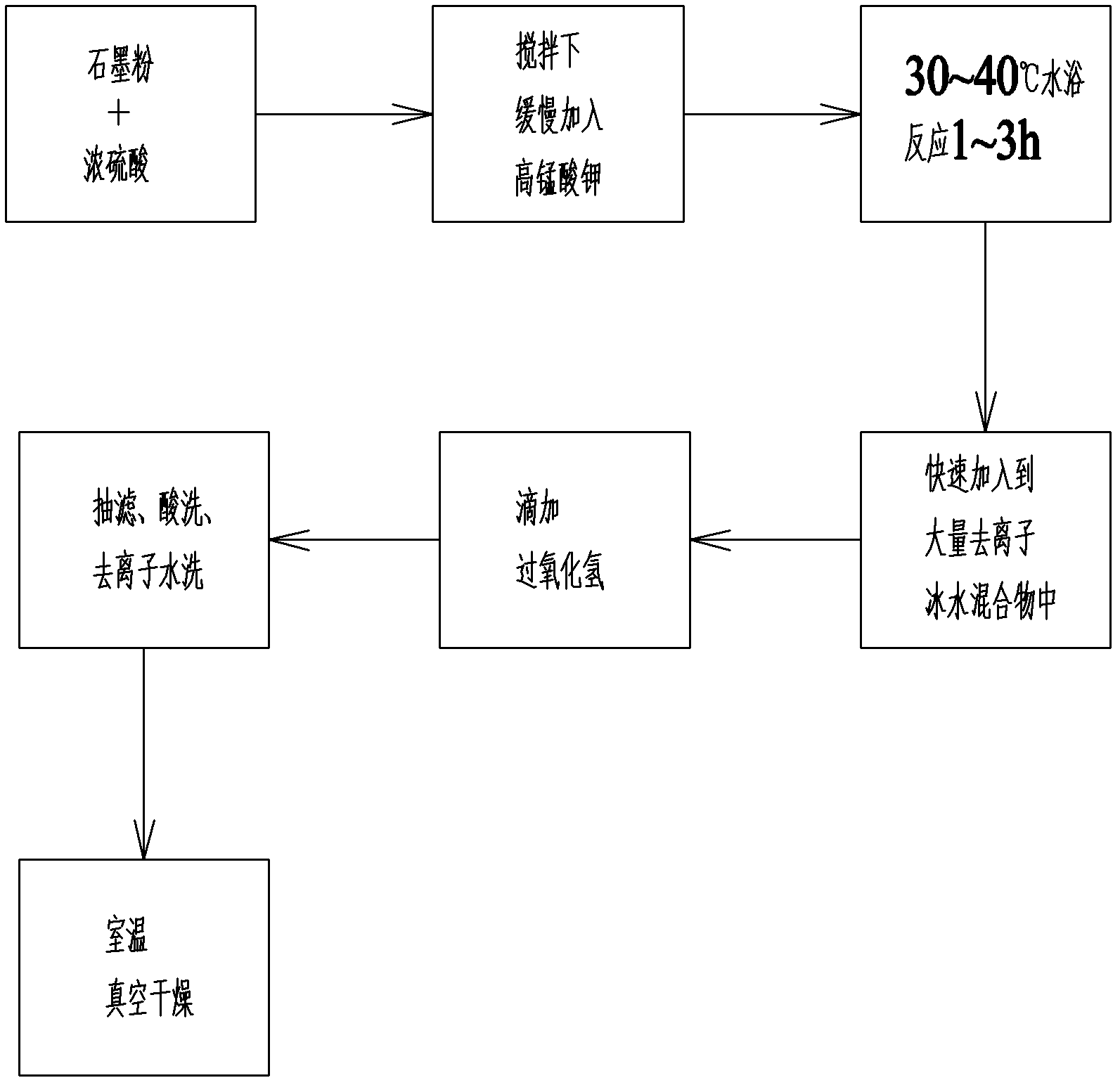

[0023] A method for diluting concentrated sulfuric acid with ice-water mixture in the preparation of graphite oxide of the present invention comprises the following preparation steps:

[0024] 1. Weigh 25g of Baichuan 200 mesh natural flake graphite powder, pour it into a round bottom flask with a funnel, take 1L of concentrated sulfuric acid with a weight percentage of 98% and slowly pour it into the round bottom flask, and connect it to an electric stirrer;

[0025] 2. Set the stirring speed to 100 rpm, weigh 87.5g of potassium permanganate, and gradually add it to the concentrated sulfuric acid graphite powder solution within 20 minutes;

[0026] 3. Soak the round bottom flask in a water bath, set the temperature of the water bath to 35°C for 2 hours, and set the stirring speed to 200 rpm;

[0027] 4. After the reaction is finished, quickly add it into a beaker containing 6L of deionized ice-water mixture (ice: water mass ratio is 1:1), and the stirring speed of the connect...

Embodiment 2

[0032] A method for diluting concentrated sulfuric acid with ice-water mixture in the preparation of graphite oxide of the present invention comprises the following preparation steps:

[0033] 1. Weigh 25g of Baichuan 200 mesh natural flake graphite powder, pour it into a round bottom flask with a funnel, take 1L of concentrated sulfuric acid with a weight percentage of 98% and slowly pour it into the round bottom flask, and connect it to an electric stirrer;

[0034] 2. Set the stirring speed to 100 rpm, weigh 87.5g of potassium permanganate, and gradually add it to the concentrated sulfuric acid graphite powder solution within 20 minutes;

[0035] 3. Soak the round bottom flask in a water bath, set the temperature of the water bath to 35°C for 2 hours, and set the stirring speed to 200 rpm;

[0036] 4. After the reaction is finished, quickly add it into a beaker containing 5L of deionized ice-water mixture (ice: water mass ratio is 1: 1), and the stirring speed of the connec...

Embodiment 3

[0041] A method for diluting concentrated sulfuric acid with ice-water mixture in the preparation of graphite oxide of the present invention comprises the following preparation steps:

[0042] 1. Weigh 25g of Baichuan 200 mesh natural flake graphite powder, pour it into a round bottom flask with a funnel, take 1.25L of 98% concentrated sulfuric acid by weight and slowly pour it into the round bottom flask, and connect it to an electric stirrer;

[0043] 2. Set the stirring speed to 100 rpm, weigh 87.5g of potassium permanganate, and gradually add it to the concentrated sulfuric acid graphite powder solution within 20 minutes;

[0044] 3. Soak the round bottom flask in a water bath, set the temperature of the water bath to 35°C for 1 hour, and set the stirring speed to 200 rpm;

[0045] 4. After the reaction is completed, quickly add it to a beaker containing 6.25L of deionized ice-water mixture (the mass ratio of ice: water is 3:2), and the stirring speed of the electric stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com