Process method for preparing ltcc amorphous glass porcelain powder with microwave plasma torch

A plasma torch and amorphous glass technology, which is applied in the field of electronic materials and devices, can solve the problems affecting the purity of LTCC ceramic powder, waste of crucibles, and difficulty in guaranteeing product consistency. Good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

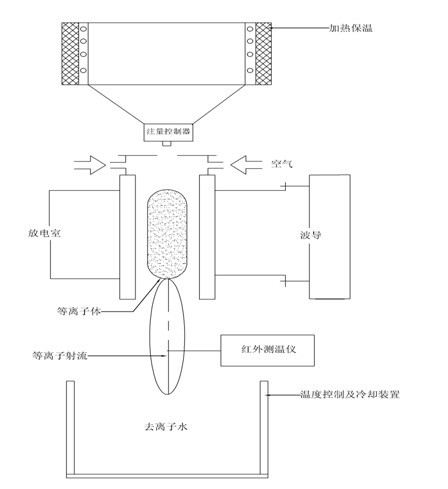

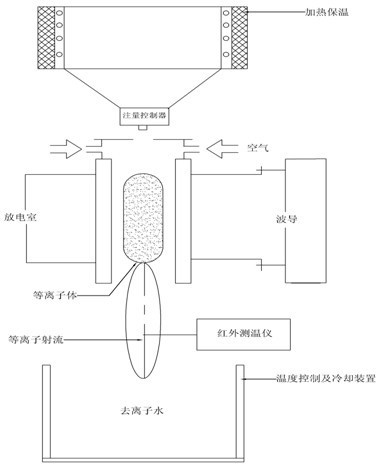

Image

Examples

Embodiment 1

[0030] A kind of microwave plasma torch prepares the processing method of LTCC amorphous glass porcelain powder, it is characterized in that processing steps are as follows:

[0031] A. Batching, mixing, ball milling

[0032] Al 2 o 3 (99%), SiO 2 (99%), B 2 o 3 ·3H 2 O (99%), MgO (99%), ZrO 2 (99%), H 3 PO 4 (80%) were made into glass raw materials according to the weight percentages of 28.58%, 25.47%, 35.21%, 6.90%, 0.50%, and 3.34%. Water and zirconia balls, the weight ratio of glass raw materials to deionized water and zirconia is 1:1:1, and wet ball milling is used for 24 hours;

[0033] B. Drying, granulation, sintering

[0034] After the ball-milled glass raw material is discharged, it is dried and ground at 100°C to form 10-40μm powder, and 10wt% polyvinyl butyral (PVB) aqueous solution is added as a binder, and the concentration of the aqueous solution is 10wt%. , after mixing evenly, use a spinning granulator to granulate into φ2mm particles, after debindi...

Embodiment 2

[0044] A kind of process method of microwave plasma torch preparation LTCC amorphous glass porcelain powder, it is characterized in that process steps are as follows:

[0045] A. Batching, mixing, ball milling

[0046] Al 2 o 3 (99%), SiO 2 (99%), B 2 o 3 ·3H 2 O (99%), MgO (99%), ZrO 2 (99%), H 3 PO 4 (80%), Sb 2 o 3 (99%) and BaO (99%) were formulated into glass raw materials according to the weight percentages of 8.94%, 52.34%, 24.89%, 2.44%, 1.86%, 1.52%, 0.13%, and 7.88%, respectively. The raw material of weighing quality again is small, adds deionized water and zirconia ball, and the weight ratio of glass raw material and dehydrated alcohol, zirconia is 1:1:2, adopts wet ball milling 22 hours;

[0047] B. Drying, granulation, sintering

[0048] After the ball-milled glass raw material is discharged, it is dried and ground at 120°C to form 10-40μm powder, and 5wt% polyvinyl butyral (PVB) aqueous solution is added as a binder, and the concentration of the aqueo...

Embodiment 3

[0058] A kind of process method of microwave plasma torch preparation LTCC amorphous glass porcelain powder, it is characterized in that process steps are as follows:

[0059] A. Batching, mixing, ball milling

[0060] The chemical raw materials BaO (99%), SiO 2 (99%), B 2 o 3 ·3H 2 O (99%), MgO (99%), CaO (99%), ZrO 2 (99%) were made into glass raw materials according to the weight percentages of 8.03%, 28.56%, 17.08%, 4.94%, 22.86%, and 18.53%. Water and zirconia balls, the weight ratio of glass raw materials to deionized water and zirconia is 1:2:4, and wet ball milling is used for 20 hours;

[0061] B. Drying, granulation, sintering

[0062] After the ball-milled glass raw material is discharged, it is dried and ground at 120°C to form 10-40μm powder, and 15wt% polyvinyl alcohol (PVA) aqueous solution (%) is added as a binder. The concentration of the aqueous solution is 8wt%, and mixed After uniformity, use a spinning granulator to granulate into φ3mm particles. Af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com