Method for preparing porous calcium phosphate biological ceramic material

A bioceramic material, porous calcium phosphate technology, applied in the field of materials and biomedicine, can solve the problems of easy inflammation, residual plastic particles, complex process, etc., and achieve uniform pore size and pore distribution, simple method and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

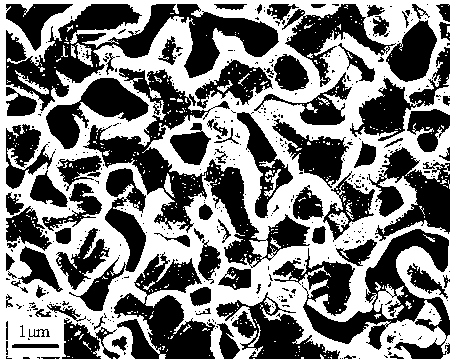

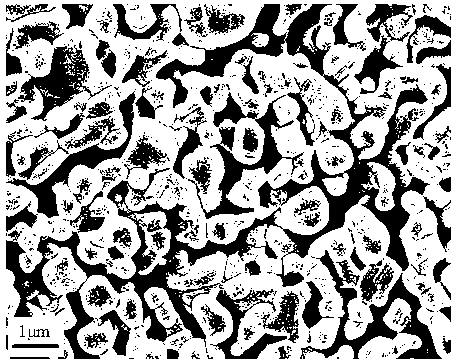

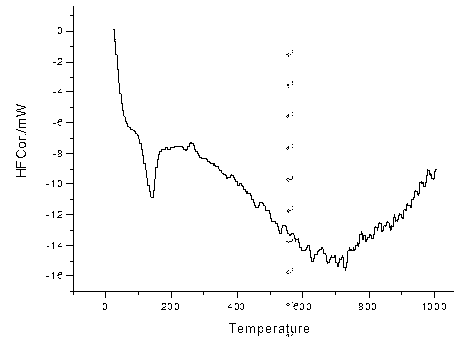

[0037] Put OCP (octacalcium phosphate) powder into a stainless steel mold, compact it under the condition of a pressure of 20MPa, then keep it under this pressure for 10min, and take out the green body; o C / min heating rate to 300 o Sinter at C, vaporize to remove crystal water, keep at this temperature for 2 hours and then heat to 900 o C undergoes a phase transition, and then naturally cools in the furnace to obtain a β-TCP porous bioceramic with a pore size of 1–5 μm and a porosity of 22%.

Embodiment 2

[0039] Put DCPD (calcium hydrogen phosphate dihydrate) powder into a stainless steel mold, compact it under the condition of a pressure of 20 MPa, and then keep it under this pressure for 10 minutes, and take out the green body; o C / min heating rate to 300 o Sinter at C, vaporize to remove crystal water, keep at this temperature for 2 hours and then heat to 900 o C undergoes a phase transition, and then naturally cools in a furnace to obtain a porous HA bioceramic with a pore size of 1–5 μm and a porosity of 37%.

Embodiment 3

[0041] Mix OCP and DCPD powders at a ratio of 1:1, put the mixed powder into a stainless steel mold, compact it under the condition of a pressure of 20MPa, and then keep it under the pressure for 10min, and take out the green body; after compaction, get The green body is 20 o C / min heating rate to 300 o Sinter at C, vaporize to remove crystal water, keep at this temperature for 2 hours and then heat to 900 o C undergoes a phase transition, and then naturally cooled in a furnace to obtain a biphasic porous bioceramic of β-TCP and HA with a pore size of 1–5 μm and a porosity of 29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com