A method for preparing L-ribose by reducing ketose by catalytic hydrogenation

A ribose and catalyst technology, which is applied in the field of preparing L-ribose by reducing ketose by catalytic hydrogenation, can solve the problems of high reaction temperature, poor atom economy, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

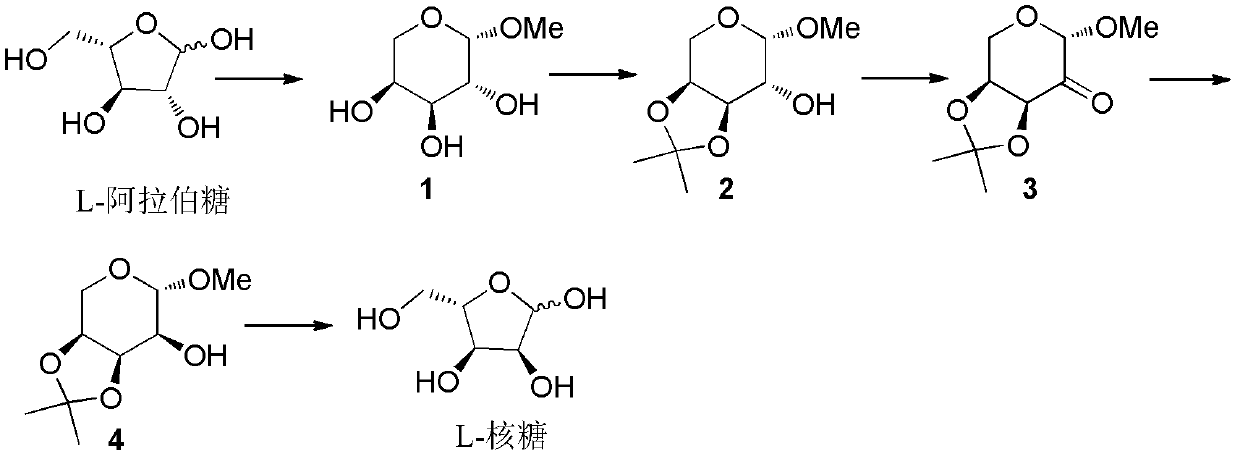

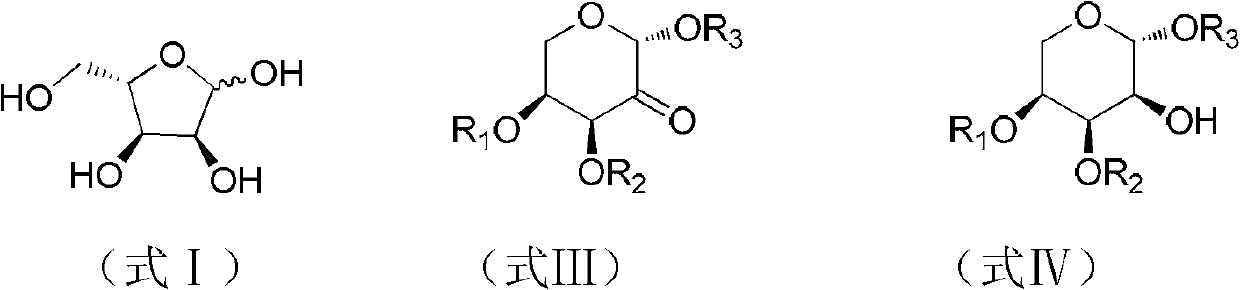

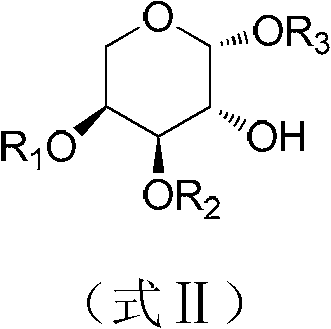

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, preparation L-ribose

[0034] The mixed system of 5g Raney Ni (Raney nickel), 200mL methanol and 10g 3,4-O-propylidene-2-deoxy-2-oxo-β-L-arabinoside (compound 3) was dissolved in 30atm hydrogen React under pressure for 72 hours at a reaction temperature of 20-30°C. The catalyst was filtered off, and the filtrate was spin-dried to obtain a pale yellow oily liquid. The product has been 1 H NMR detection found to contain 3,4-O-propylidene-β-L-arabinoside 2 (content 8%) and 3,4-O-propylidene-β-L-riboside 4 (content 92%) ). The conversion efficiency was 92%. "Transformation efficiency" in the present invention refers to the generated 3,4-O-propylidene-β-L-riboside 4 relative to the 3,4-O-propylidene-2-deoxy-2- Oxo-β-L-arabinoside 3 ratio.

[0035] The NMR characterization of the resulting reduction product 3,4-O-propylidene-β-L-riboside 4 is as follows: 1 H-NMR (300MHz, CDCl 3 ), δ (ppm), 4.64 (1H, d, J = 3.5Hz, H1), 4.38 (1H, dd, J = 6.7Hz, 3.9Hz, H3),...

Embodiment 2

[0038] A mixed system of 50mg Pd / C (10%), 20mL ethanol and 100mg 3,4-O-propylidene-2-deoxy-2-oxo-β-L-arabinoside (compound 3) was dissolved in 50atm hydrogen React under pressure for 48 hours, and the reaction temperature is 28-35°C. The catalyst was filtered off, and the filtrate was spin-dried to obtain a pale yellow oily liquid. The product has been 1 H NMR detection found that it contained 3,4-O-propylidene-β-L-arabinoside 2 (content 9%), ketose 3 (content 85%) and 3,4-O-propylidene-β-L - Riboside 4 (content 6%). The conversion efficiency was 38%. The product was recrystallized in a mixed solvent of ethyl acetate / petroleum ether, and then separated by column chromatography (mobile phase: ethyl acetate / petroleum ether=1 / 3, v / v) to obtain 3,4-O-propylidene- β-L-riboside 4.

[0039] The resulting reduction product 3,4-O-propylidene-β-L-riboside 4 was reacted at 90°C for 12 hours in the presence of a macroporous strongly acidic styrene-based cation exchange resin to obtai...

Embodiment 3

[0041] 50mg Pd(OH) 2 , 20mL of methanol and 100mg of 3,4-O-propylidene-2-deoxy-2-oxo-β-L-arabinoside 3 mixed system was reacted under 50atm hydrogen pressure for 72 hours, and the reaction temperature was 30-40°C . The catalyst was filtered off, and the filtrate was spin-dried to obtain a pale yellow oily liquid. The product has been 1 H NMR detection found that it contained 3,4-O-propylidene-β-L-arabinoside 2 (content 11%), ketose 3 (content 67%) and 3,4-O-propylidene-β-L - Riboside 4 (content 22%). The conversion efficiency was 68%. The product was recrystallized in a mixed solvent of ethyl acetate / petroleum ether, and then separated by column chromatography (mobile phase: ethyl acetate / petroleum ether=1 / 3, v / v) to obtain 3,4-O-propylidene- β-L-riboside 4.

[0042] The resulting reduction product 3,4-O-propylidene-β-L-riboside 4 was reacted at 90°C for 12 hours in the presence of a macroporous strongly acidic styrene-based cation exchange resin to obtain L-ribose, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com