deicing agent

A snow melting agent and silicate technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as water eutrophication, achieve low biochemical and chemical oxygen consumption, high work efficiency, and strong snow melting ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

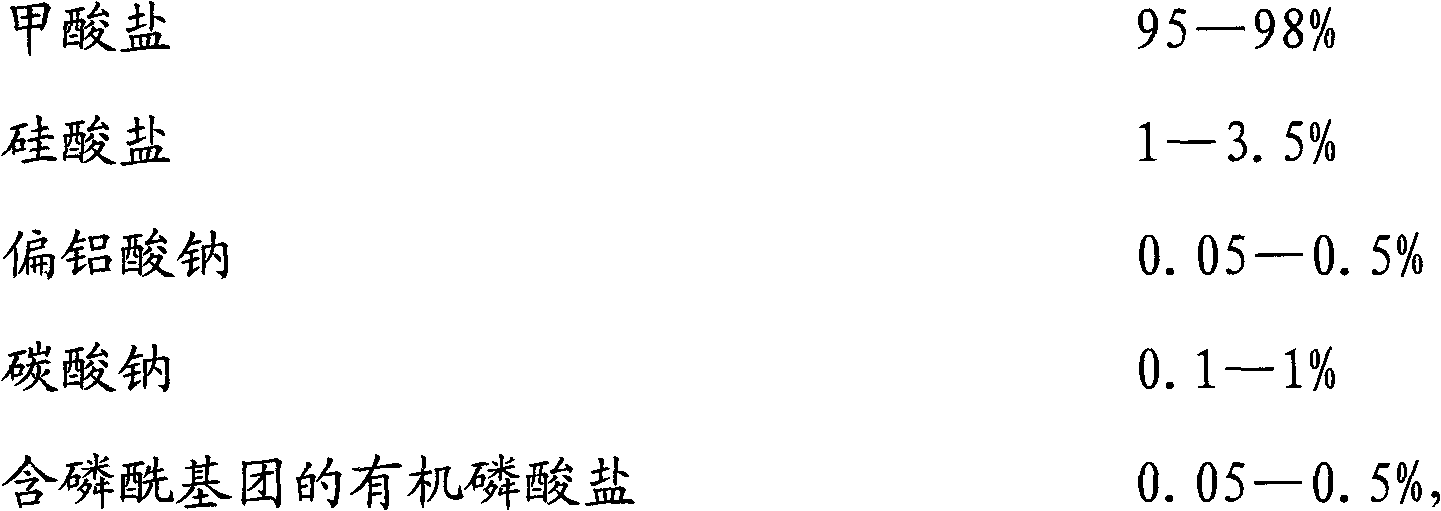

[0066] A kind of snow melting agent, the weight percentage of each component is:

[0067]

[0068] The modulus of sodium disilicate is 1.

[0069] The production method is as follows: take each component according to the weight percentage, crush, mix and stir evenly, then extrude it into 2-6mm granules, and dry to get it.

Embodiment 6

[0071] A kind of snow melting agent, the weight percentage of each component is:

[0072]

[0073]

[0074] The modulus of sodium disilicate is 3.5.

[0075] The production method is the same as in Example 5.

Embodiment 7

[0077] A kind of snow melting agent, the weight percentage of each component is:

[0078]

[0079] The modulus of sodium disilicate is 2.

[0080] The production method is the same as in Example 5.

[0081] Of course, the present invention can also have other various embodiments, such as replacing sodium formate with other formates, for example, potassium formate, or partially with potassium formate; all or part of sodium disilicate is replaced with other silicates Substitute, for example, with one or more of sodium metasilicate, potassium disilicate, potassium metasilicate; phosphoryl group [-PO(OH) 2 ] organic phosphate is not limited to disodium hydroxyethylene diphosphate (HEDPNa 2 ), 2-phosphobutane-1,2,4-tricarboxylate tetrasodium (PBTCANa 4 ), one of sodium a-hydroxyphosphonate acetate (HPAANa), or a combination of two or three. As long as the weight percentage of each component is within the scope of the present invention, the purpose of the present invention ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com