A kind of trichlorethylene polluted soil oxidizer and its preparation and use method

A technology of polluted soil and trichlorethylene, which is applied in the field of remediation of trichlorethylene-contaminated soil, can solve problems such as slow reaction rate, and achieve the effect of low cost, low cost and easy biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

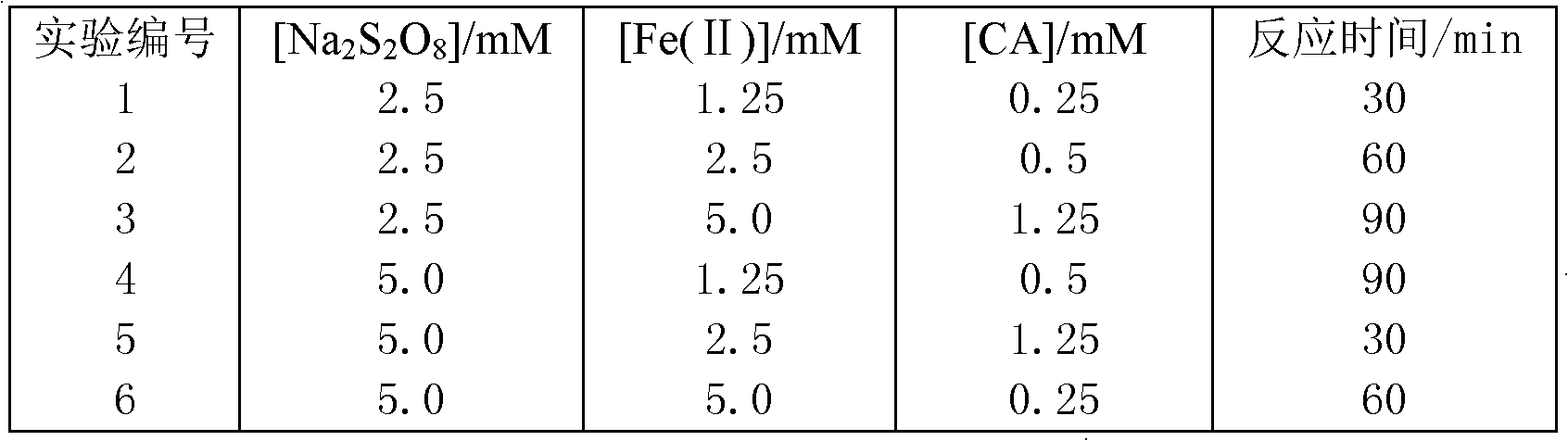

[0023] Example 1: Comparison of the removal effect of medicament ratio and concentration combination

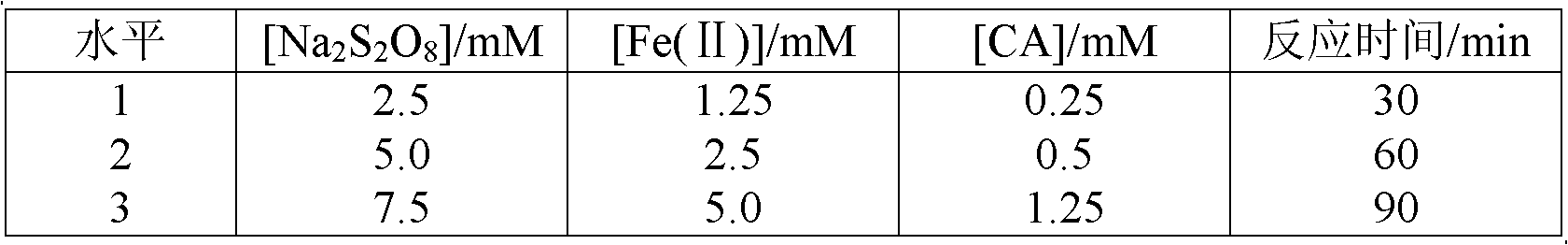

[0024] 1. Under the condition of soil sample TCE pollution concentration of 100mg / kg, it is designed to use Na 2 S 2 O 8 Concentration, FeSO 4 Concentration, CA concentration, and reaction time are a 4-factor 3-level orthogonal test (see Table 1). The concentration of each component, that is, the experimental design concentration, is the concentration of the oxidizer and the activator mixed.

[0025] 2. Weigh Na 2 S 2 O 8 Dissolve into Na with a concentration of 1.2~3.6g / L in tap water 2 S 2 O 8 Solution, as oxidant; also called FeSO 4 ·7H 2 O and CA, dissolved in tap water to form FeSO 4 -CA mixed solution, the two concentrations in the mixed solution are respectively 0.7~2.8g / L and 0.1~0.5g / L, as activator.

[0026] 3. Weigh 10g of spare soil sample (TCE concentration is 100mg / kg) into a 100mL centrifuge tube, add FeSO 4 -CA mixed solution 15mL, shake well, add Na 2 S 2 O 8 The sol...

Embodiment 2

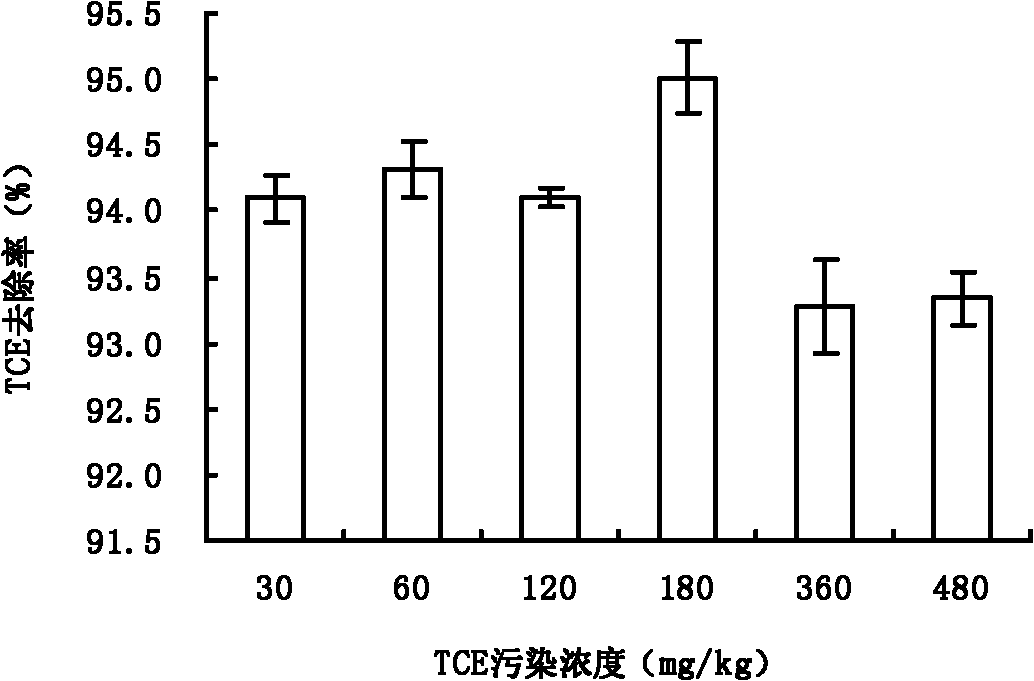

[0034] Example 2: Na 2 S 2 O 8 -FeSO 4 -The removal effect of CA oxidizer on soil with different TCE contaminated concentration

[0035] 1. Weigh Na according to the best conditions determined in Example 1 2 S 2 O 8 , Dissolved in tap water to a concentration of 2.4g / L Na 2 S 2 O 8 Solution; also called FeSO 4 ·7H 2 O and CA, dissolved in tap water to form FeSO 4 -CA mixed solution, the two concentrations are 1.4g / L and 0.1g / L respectively.

[0036] 2. Weigh 10g of spare soil sample (TCE concentration is 30~480mg / kg) into a 100mL centrifuge tube, add FeSO 4 -CA mixed solution 15mL, shake well, add Na 2 S 2 O 8 The solution was 15 mL, so that the final concentration of each agent reached the best condition in Example 1. The reaction flask was placed in a shaker and shaken at a speed of 300 r / min, protected from light, and the temperature was constant at 25°C. Simultaneous blank processing and 3 replicate samples. Sampling was taken at the time of the experimental design, and the TCE...

Embodiment 3

[0039] 1. Preparation of medicine

[0040] Weigh Na 2 S 2 O 8 , Use tap water to dissolve to a concentration of 1.2g / L and a volume of 1L as an oxidant; also weigh FeSO 4 ·7H 2 O and CA are dissolved in tap water to form a mixed solution, the concentrations of the two are 0.7g / L and 0.1g / L, and the volume is 1L, as activators.

[0041] 2. Oxidation of soil column: The column body is made of a PVC pipe with a length of 50cm and an inner diameter of 7.5cm through a wire mesh and glass fiber backing. The soil density in the column is 1.4g / cm 3 , The height of the soil column is 40cm, and the TCE concentration is 300mg / kg. The activator and the oxidant are uniformly injected from the upper end of the soil column at the same time, the flow rate is about 0.30mL / min, the total injection volume is 2L, and the lower end of the soil column is drained. 2 duplicates. After the oxidation, the TCE concentration in the soil was measured, and the removal rate was 91.3%.

[0042] Compared with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com