Biomass pyrolysis liquefied fuel oil technology

A biomass thermal cracking and biomass technology, which is applied in the field of biomass preparation of bio-oil, can solve the problems of high oxygen content, high bio-oil viscosity and high cost, and achieve high oil quality, high energy density, and increased yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

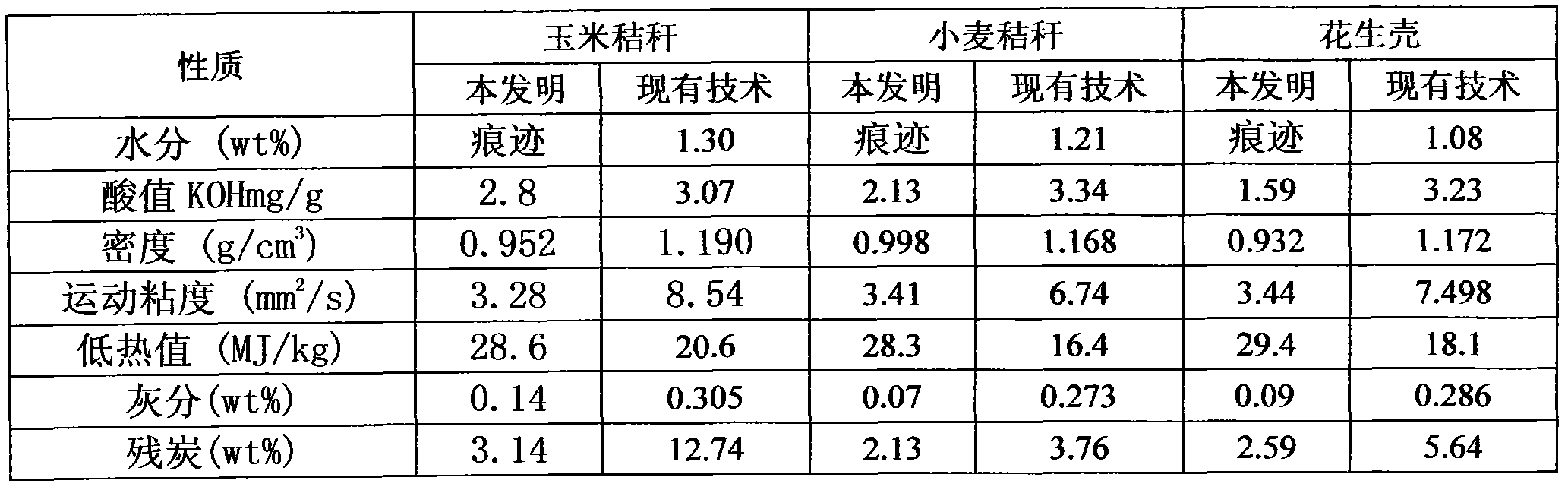

specific Embodiment 1

[0016] Specific embodiment 1: take corn stalk as example:

[0017] A biomass pyrolysis liquefied fuel oil technology, comprising the following process steps:

[0018] (1) Pretreatment of corn stalks:

[0019] Water, 5mol / L hydrochloric acid, and hydrofluoric acid are used to configure the soaking solution according to the volume ratio of 20:1:0.5, and the corn stalks are soaked in the soaking medium for 30 minutes. Drying the corn stalks so that the moisture content of the corn stalks is dried to less than 8% of the corn stalks mass; cutting the dried corn stalks into lengths of 3-5mm;

[0020] (2) Thermal cracking of corn stalks

[0021] Transport the cut corn stalks to the fluidized bed, control the feed rate at 20kg / h, crack under anaerobic conditions at 500°C, adjust the flow rate of the carrier gas, and control the residence time of the cracked gas between 0.8s, and the pyrolysis gas leaves the reaction After entering the cyclone separator, the charcoal is separated by...

specific Embodiment 2

[0024] Specific embodiment 2: take wheat straw as example:

[0025] A biomass pyrolysis liquefied fuel oil technology, comprising the following process steps:

[0026] (1) Wheat straw pretreatment:

[0027] Water, 5mol / L hydrochloric acid, and hydrofluoric acid are used to configure the soaking solution according to the volume ratio of 20:1:0.5, and the wheat straw is placed in the soaking medium for 30 minutes, and the liquid surface is submerged in the wheat straw to remove ash; dry the wheat straw so that the moisture content of the wheat straw is dried to less than 8% of the wheat straw mass; the dried wheat straw is cut into a length of 3-5mm;

[0028] (2) Pyrolysis of wheat straw

[0029] Transport the cut wheat straw to the fluidized bed, control the feed rate at 200kg / h, crack under anaerobic conditions at 650°C, adjust the flow rate of the carrier gas, and control the residence time of the cracked gas between 1.2s, and the pyrolysis gas leaves the reaction After en...

specific Embodiment 3

[0032] Specific embodiment 3: take peanut shell as example:

[0033] A biomass pyrolysis liquefied fuel oil technology, comprising the following process steps:

[0034] (1) Peanut shell pretreatment:

[0035] Water, 5mol / L hydrochloric acid, and hydrofluoric acid are used to prepare the soaking liquid according to the volume ratio of 20:1:0.5, and the peanut shells are placed in the soaking water for 30 minutes. Dry the peanut shells so that the moisture content of the peanut shells is dried to be lower than 8% of the mass of the peanut shells; the dried peanut shells are cut into lengths of 3-5mm;

[0036] (2) Pyrolysis of peanut shells

[0037] Transport the cut peanut shells to the fluidized bed, control the feed rate at 100kg / h, crack under anaerobic conditions at 550°C, adjust the flow rate of the carrier gas, control the residence time of the cracked gas between 1s, and the pyrolysis gas leaves the reactor Finally, it enters the cyclone separator, relying on centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com