Lubricant composition for transmission system of wind power equipment

A technology of lubricant composition and transmission system, applied in the directions of lubricating composition, additives, petroleum industry, etc., can solve problems such as unreported, and achieve the effects of protecting pitting damage, excellent low-temperature start-up performance, and excellent anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The lubricant composition of the transmission system of wind power equipment in this embodiment includes: 0.5% of the friction index improver dimerized linoleic acid, 1% of sulfurized isobutylene as an extreme pressure and antiwear agent, 0.5% of polymethacrylate as a pour point depressant, anti-oxidation and anti-corrosion Agent 2, 6-di-tert-butyl-p-cresol 0.1%, compound antifoam agent PRS-6A 0.01%, anti-emulsifier polyisobutylene succinate 0.1%, antirust agent neutral barium dinonyl naphthalene sulfonate 0.05%, viscosity index improver polymethacrylate 10%, polyalphaolefin 77.74%, and polyol fat 10%, all contents are in mass percent.

[0045] Preparation method: Stir and blend each component at 55°C for 3 hours, then analyze and test the viscosity, viscosity index, anti-foaming performance, and anti-emulsifying performance. After testing, the specific testing results are shown in Table 2.

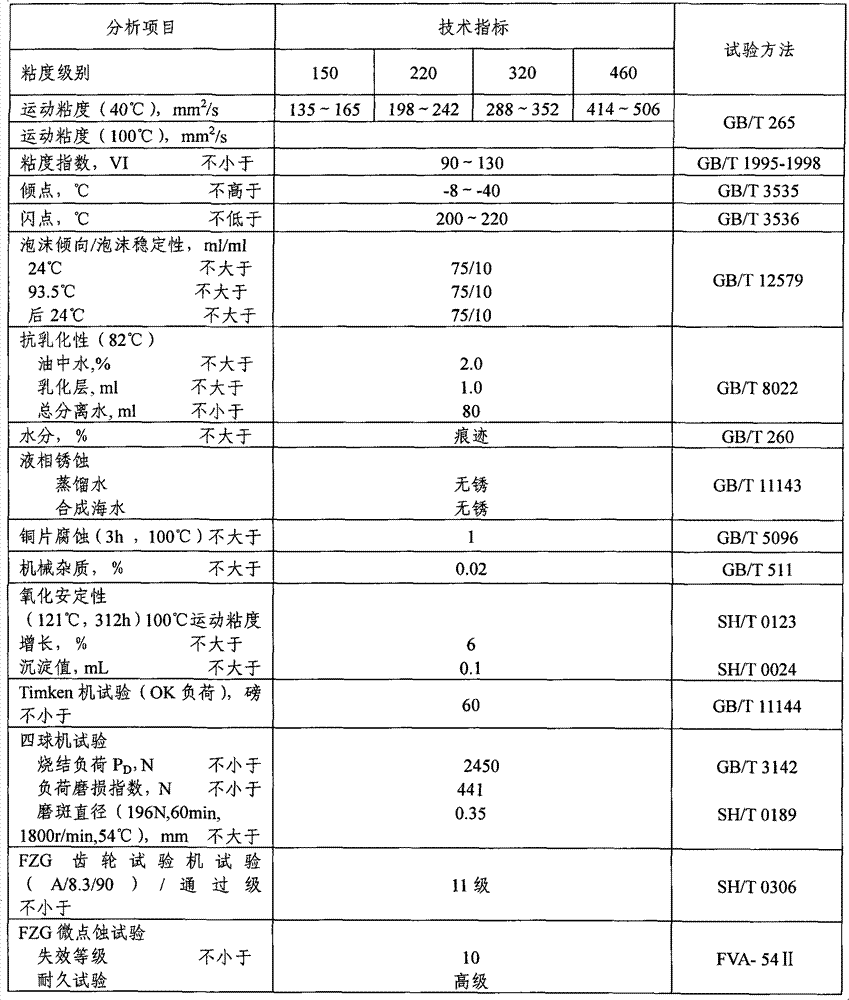

[0046] Table 2

[0047]

[0048]

Embodiment 2

[0050] The lubricant composition of the transmission system of wind power equipment in this embodiment includes: friction index improver butyl oleate 0.1%, extreme pressure and antiwear agent tricresyl phosphate 1%, pour point depressant polyacrylate 0.4%, antioxidant and anticorrosion agent Phenyl-α-naphthalene ammonia 0.5%, anti-foaming agent silicone oil T9010.01%, anti-emulsifier succinimide 0.5%, anti-rust agent alkyl succinic acid derivative 0.1%, viscosity index improver polyisobutylene 5 %, paraffin-based mineral oil 92.39%, and the contents are all mass percentages.

[0051] Preparation method: Stir and blend each component at 60°C for 3 hours, then analyze and test the viscosity, viscosity index, anti-foaming performance, anti-emulsifying performance and other items. After testing, the specific testing results are shown in Table 3.

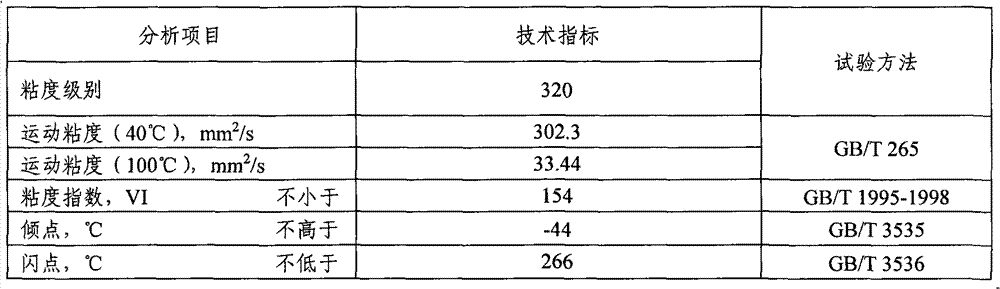

[0052] table 3

[0053]

[0054]

Embodiment 3

[0056]The lubricant composition of the transmission system of wind power equipment in this embodiment includes: friction index improver ethylene glycol oleate 0.3%, extreme pressure antiwear agent dimethyl dithiophosphate 1%, pour point depressant vinyl acetate / trans-butyl 1.0% alkene ester copolymer, 0.2% anti-oxidant and anti-corrosion agent diethyldithiocarbamate, 0.3% anti-oxidant and anti-corrosion agent 2, 6-di-tert-butyl-p-cresol, anti-foaming agent T9110 .005%, anti-emulsifier sorbitan oleate polyoxyethylene ether 0.001%, rust inhibitor neutral barium dinonyl naphthalene sulfonate 0.1%, viscosity index improver polymethacrylate 3%, paraffinic mineral oil 70%, and 24.094% of the mixture of polyalphaolefins, the contents are all in mass percent.

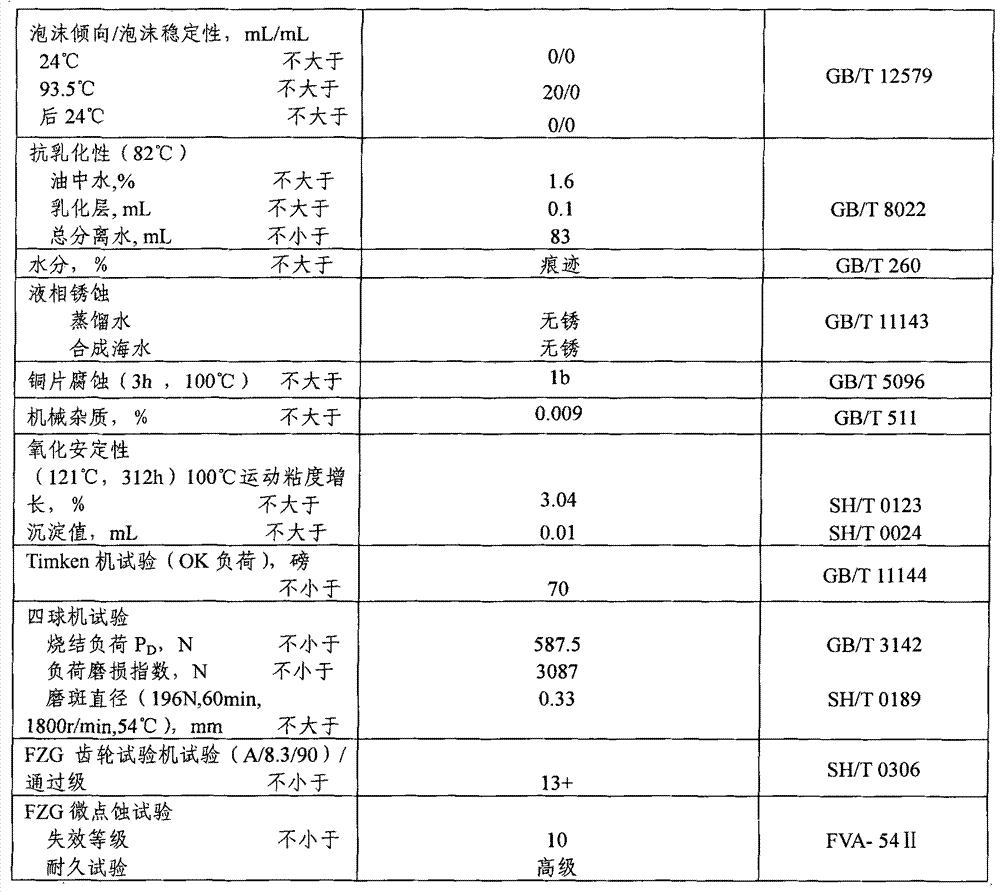

[0057] Preparation method: Stir and blend each component at 60°C for 2 hours, then analyze and test the viscosity, viscosity index, anti-foaming performance, and anti-emulsifying performance. After testing, the specific testing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com