Chemical-medium-resistant fluorosilicone lubricating grease and preparation method thereof

A lubricating grease and chemical-resistant technology, which is applied in the field of chemical-resistant fluorosilicon grease and its preparation, can solve the problems of solvent resistance, insufficient high temperature resistance, performance degradation and aging of lubrication protection, etc., and achieve good chemical-resistant performance , Improve high temperature performance and good lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

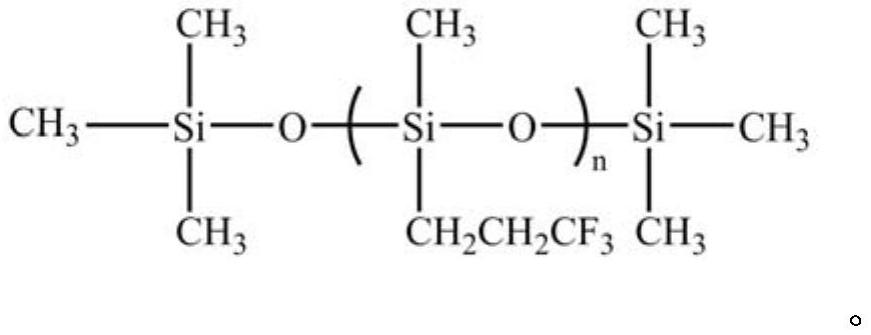

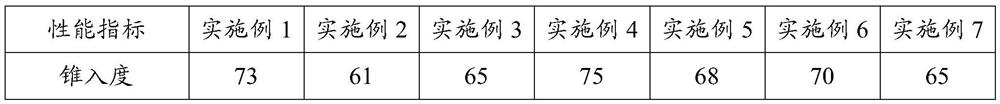

[0047] Select the kinematic viscosity at 25°C as 3000mm 2 / s fluorosilicone oil and linear perfluoropolyether oil (p=5~35, q=0.25~0.87) with an average molecular weight of 1000~3000, mix the two and heat to 35°C, stir mechanically for 1.5h to obtain a compound Fluorine-containing base oil (6wt% linear perfluoropolyether oil and 94wt% fluorosilicone oil); add 60g of composite fluorine-containing base oil to the grease stirring reactor, heat to 60°C, keep the temperature for 30min, add tetrafluoroethylene Ethylene-hexafluoropropylene copolymer thickener, its weight is 22g, stirred for 1h; after cooling to room temperature 25°C, add high-temperature performance improver chlorotrifluoroethylene telomer, its weight is 6g, stirred for 30min; use grinding equipment to grind 3 times, and then carry out vacuum degassing post-treatment to the lubricating grease after grinding, and the properties of the finished lubricating grease are as shown in Table 1 below.

Embodiment 2

[0049] Select the kinematic viscosity at 25°C as 5000mm 2 / s fluorosilicone oil and linear perfluoropolyether oil with an average molecular weight of 2,000 to 5,000 are mixed, heated to 40°C, and mechanically stirred for 1.5 hours to obtain a composite fluorine-containing base oil (5wt% linear perfluoropolyether oil) ether oil and 95wt% fluorosilicone oil); add 68g of composite fluorine-containing base oil in the grease stirring reactor, heat to 60°C, keep the temperature for 30min, add tetrafluoroethylene-hexafluoropropylene copolymer, its weight is 10g, Stir for 1 hour; cool to room temperature at 20°C and add silica, a high-temperature performance improver with a weight of 9 g, and stir for 30 minutes; use grinding equipment to grind twice, and then perform vacuum degassing post-treatment on the ground grease to obtain lubricating oil Fat products, packaging.

Embodiment 3

[0051] Select the kinematic viscosity at 25°C as 10000mm 2 / s fluorosilicone oil and linear perfluoropolyether oil with an average molecular weight of 3,000 to 6,000 are mixed, heated to 40°C, and mechanically stirred for 1.5 hours to obtain a composite fluorine-containing base oil (8wt% linear perfluoropolyether oil) ether oil and 92wt% fluorosilicone oil); add 70g of composite fluorine-containing base oil to the grease stirring reactor, heat to 60°C, keep the temperature constant for 30min, add polytetrafluoroethylene thickener with a weight ratio of 25g, and stir for 1h ;After cooling to room temperature 30°C, add the high-temperature performance improver molybdenum dioxide with a weight ratio of 5g, and stir for 30 minutes; use grinding equipment to grind twice, and then perform vacuum degassing post-treatment on the ground grease to obtain the finished grease ,Package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com