Method for nanometer ferroferric oxide modification of chinlon fabric via hydrothermal process

A technology of ferroferric oxide and hydrothermal method, which is applied in textiles, papermaking, fiber treatment, etc. It can solve the problems of non-magnetic, poor hand feeling and air permeability, and unsustainable washing performance of nylon fabrics, so as to save raw materials and durability. Good washing performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

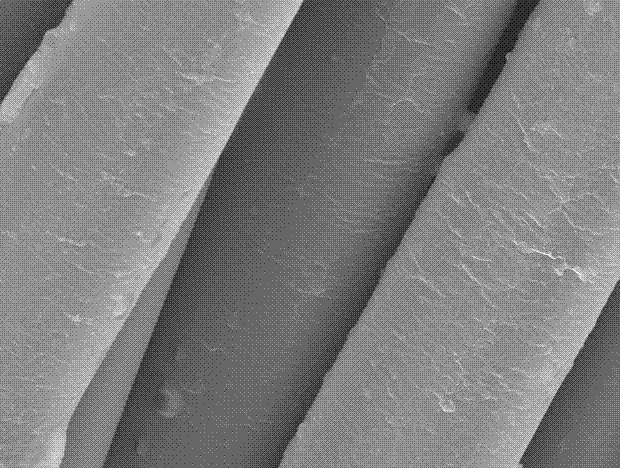

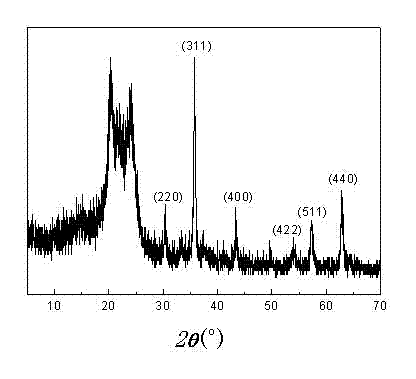

[0031] Prepare a 300ml / L dilute solution with hydrochloric acid with a mass-volume concentration of 36%, roughen the nylon fabric at 40°C for 1 hour, then wash it with deionized water, and dry it at 60°C. Weigh a certain amount of ferrous chloride and ferric trichloride, dissolve it in a mixed solution with a volume ratio of dimethylformamide and deionized water of 1:7, control the total iron concentration to 0.01mol / L, and ferrous chloride The mass ratio to ferric chloride is 1:2, then add 0.8g of sodium lauryl sulfate and 20g of urea, stir well until completely dissolved, soak the roughened nylon fabric for 5min, and then the fabric together with the solution Move them together into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, seal it, put it into a homogeneous reactor, and treat it at 110°C for 5 hours at a rate of 30r / min. After the reaction is complete, take out the nylon fabric and dry it in vacuum at 60°C Dry in the oven for 10 minutes, an...

Embodiment 2

[0034] Prepare a 100ml / L dilute solution with hydrochloric acid with a mass-volume concentration of 36%, roughen the nylon fabric at 60°C for 5 hours, then wash it with deionized water and dry it. Weigh a certain amount of ferrous chloride and ferric trichloride, dissolve it with a mixed solution of dimethylformamide and deionized water with a volume ratio of 4:4, control the total iron concentration to 0.1mol / L, ferrous chloride and The mass ratio of ferric chloride is 1:1, then add 0.6g of sodium lauryl sulfate and 16g of urea, stir well until completely dissolved, dip the roughened nylon fabric for 10min, then fabric together with the solution Move them together into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, seal it and put it into a homogeneous reactor, treat it at a rate of 30r / min at 120°C for 4 hours, take out the nylon fabric after the reaction is over, and put it in a vacuum oven at 60°C Dry in medium temperature for 20min, wash with ...

Embodiment 3

[0037] Prepare a 200ml / L dilute solution with hydrochloric acid with a mass-volume concentration of 36%, roughen the nylon fabric at 50°C for 3 hours, then wash it with deionized water and dry it. Weigh a certain amount of ferrous chloride and ferric trichloride, dissolve them in a mixed solution with a volume ratio of dimethylformamide and deionized water of 3:5, control the total iron concentration to 0.05mol / L, and ferrous chloride The mass ratio to ferric chloride is 4:1, add 0.4g of sodium lauryl sulfate and 25g of urea, stir well until completely dissolved, soak the roughened nylon fabric for 8min, and put the fabric together with the solution Move it into a stainless steel reaction kettle with a polytetrafluoroethylene substrate, seal it, put it into a homogeneous reactor, and treat it at a rate of 30r / min at 160°C for 2h. After the reaction is complete, take out the nylon fabric and place it in a vacuum oven at 60°C. Dry for 30 minutes, wash with deionized water at 80°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com