Preparation method of light source assembly of light emitting diode (LED) lamp and LED roadway lamp involving in method

A technology for LED roadway lights and light source components, which is applied to semiconductor devices, light sources, and electric light sources of light-emitting elements. It can solve the problems of difficult control of processing compaction, increase in lamp body size, and large volume of lamps, and meet the manufacturing process conditions. It is not easy to control, the product is bulky and beautiful, and the total heat dissipation area is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

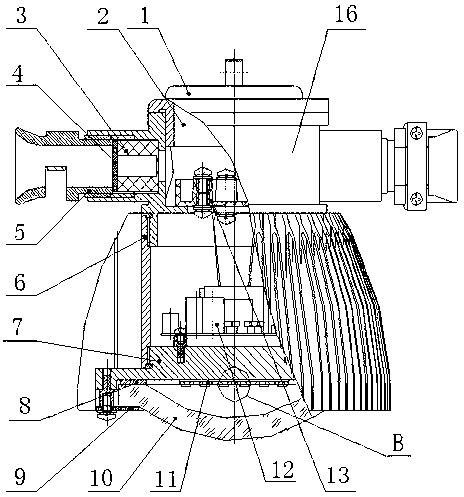

[0044] In this embodiment, twenty-eight SMD LED lamp beads with copper-based bases, copper-based LED lamp bead printed circuit boards, and aluminum-based heat conducting plates are used as components. The specific preparation method steps are as follows:

[0045] Step 1: Apply solder paste at the position where the lamp bead base of each LED lamp bead is connected to the LED lamp bead printed circuit board, and then perform hot air welding at 250°C after applying the solder paste, and then obtain an LED with LED lamp beads installed. LED printed circuit board;

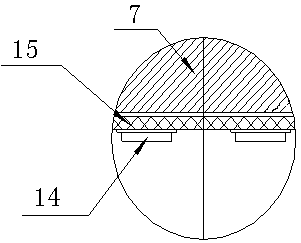

[0046] Step 2: The part where the LED printed circuit board is installed on the aluminum-based heat-conducting board is copper-plated with a bonding process, and the thickness of the copper-plated layer is 40 microns; The parts where the boards are connected are tinned by the conventional process, and the thickness of the tinned layer is 130 microns; then, apply solder paste on the entire surface where the copper-plate...

Embodiment 2

[0050] The difference between this embodiment and Embodiment 1 is that the soldering temperature between the LED lamp bead 14 and the LED lamp bead PCB 15 is 255° C., and the soldering temperature between the LED lamp bead PCB 15 and the aluminum-based heat conducting plate 7 is 250° C.

Embodiment 3

[0052] The difference between this embodiment and the first embodiment is that the soldering temperature between the LED lamp bead 14 and the LED lamp bead PCB 15 is 230° C., and the soldering temperature between the LED lamp bead PCB 15 and the aluminum-based heat conducting plate 7 is 225° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com