Preparation method of color three-dimensional hologram based on holographic polymer dispersed liquid crystal grating

A technique of dispersing liquid crystals and three-dimensional holography, which is applied in the field of preparation of color three-dimensional holograms, and can solve problems such as preparation methods that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

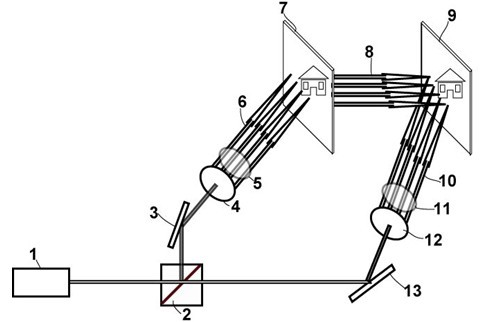

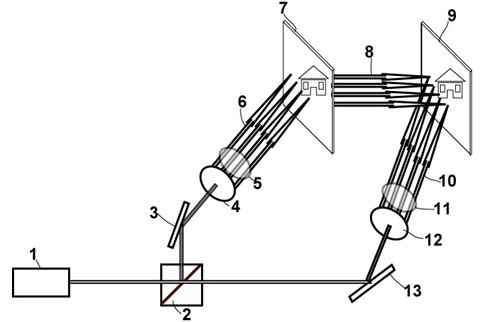

Image

Examples

Embodiment 1

[0034] In the 441.6nm laser interference field, first use holographic technology to make a holographic master that stores the reflected (or transmitted) light wave information (amplitude, phase) of the subject, and then use the object light to irradiate the holographic master in the direction of the Bragg angle. Diffraction light is generated, and the diffraction light and reference light are simultaneously irradiated by 0.01wt.% photosensitizer (1:1 3,3′-diethylthiacarbocyanine iodide and coumarin 6), 0.1wt.% co- Initiator (1:1:2 of N,N,N-triethylamine, N-methylmaleimide and 3-bromophenylglycine), 30wt.% of free radical polymerizable monomer ( 2:3:1 methyl methacrylate, methacrylamide and N-vinylpyrrolidone) and 70wt.% liquid crystal (2:1 8CB and 5CT) to prepare a holographic backplane with a thickness of 10 μm, when it reaches When the total optical path of the two laser beams of the holographic plate is equal, the two lasers will be optically coherent on the holographic pla...

Embodiment 2

[0036] In the 441.6nm laser interference field, first use holographic technology to make a holographic master that stores the reflected (or transmitted) light wave information (amplitude, phase) of the subject, and then use the object light to irradiate the holographic master in the direction of the Bragg angle. Diffraction light is generated, and the diffraction light and reference light are simultaneously irradiated by 0.01wt.% photosensitizer (coumarin 343 and 7-diethylamino-3-thienoylcoumarin of 1:2), 0.1wt.% The co-initiator (1:2:1 N-ethylmaleimide, N-phenylglycine and 2,4,6-tris(trichloromethyl)-1,3,5-triazine) , 90wt.% free radical polymerizable monomers (1:2:1 butyl acrylate, 2-isooctyl acrylate and N-isopropylacrylamide) and 10wt.% liquid crystal E7 made the thickness For a holographic base plate of 15 μm, when the total optical path of the two laser beams reaching the holographic base plate is equal, the two laser beams will be optically coherent on the holographic b...

Embodiment 3

[0038]In the 441.6nm laser interference field, first use holographic technology to make a holographic master that stores the reflected (or transmitted) light wave information (amplitude, phase) of the subject, and then use the object light to irradiate the holographic master in the direction of the Bragg angle. Generate diffracted light, and the diffracted light and reference light are simultaneously irradiated by 0.01wt.% photosensitizer (1:1 3,3'-carbonyl bis(7-diethylaminocoumarin) and 6-hydroxyl-7-formazan Oxygen-4-phenylcoumarin), 10wt.% co-initiator (2:1:1 triethanolamine, acetylphenylglycine and 3-cyanophenylglycine), 70wt.% free Based polymerized monomer (1:1:2 ethyl dimethacrylate, trimethylolpropane trimethacrylic acid and N-vinyl carbazole) and 20wt.% liquid crystal P0616A prepared a thickness of 15μm Holographic base plate, when the total optical path of the two laser beams reaching the holographic base plate is equal, the two laser beams will be optically coherent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com