A kind of transparent conductive film with high cashmere value and preparation method thereof

A technology of transparent conductive film and transparent conductive film, applied in the direction of conductive layer on insulating carrier, cable/conductor manufacturing, circuit, etc., can solve the problem of low long-wavelength light scattering ability and achieve high transmittance and low resistivity , the effect of high scattering transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1. Float glass is used as the front substrate. After ultrasonic cleaning, an aluminum-doped zinc oxide film is grown on the glass by radio frequency magnetron sputtering technology.

[0024] The above-mentioned deposition process, the selected target material is 2wt%Al 2 o 3 ZnO is doped, the gas pressure is 3mTorr, the substrate temperature is 200°C, the radio frequency power is 250W, and the flow rate of argon gas is 2sccm to deposit the ZnO transparent conductive film.

[0025] The ZnO transparent conductive film prepared by magnetron sputtering is subjected to wet etching, preferably with hydrochloric acid etching solution with a concentration of 1 wt%. By controlling the etching time to 80s, the textured ZnO transparent conductive film can be obtained.

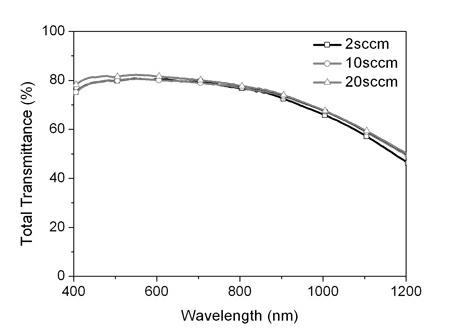

[0026] The obtained suede transparent conductive film has an average transmittance of more than 78% from 400nm to 900nm and a resistivity of less than 3.2×10 -4 Ω·cm.

Embodiment 2

[0027] Embodiment two, as described in embodiment one transparent conductive film preparation method, pass into argon gas flow rate and change 10sccm, the 400nm--900nm average transmittance of gained suede surface transparent conductive film is greater than 78%, and resistivity is less than 3 * 10 -4 Ω·cm.

Embodiment 3

[0028] Embodiment three, as the preparation method of transparent conductive film described in embodiment one, pass into argon gas flow rate and change 20sccm, the 400nm--900nm average transmittance of gained suede surface transparent conductive film is greater than 79%, and resistivity is less than 2.8 * 10 -4 Ω·cm.

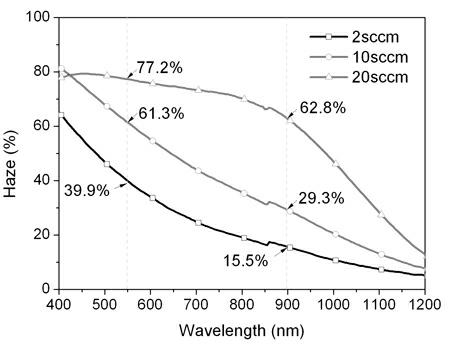

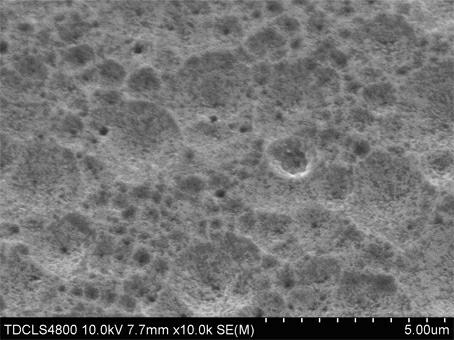

[0029] Refer to attached figure 1 , 2 , with the change of the gas flow rate, from the first embodiment to the third embodiment, the velvet of the obtained sample increases continuously. In Example 3, the velvet value at 900nm wavelength is 62.8%, and the sample has excellent light scattering ability in the spectral range of 400nm--900nm; the velvet value at 1100nm wavelength is 28.4%, and the sample has high light scattering ability in the near-infrared band. attached image 3 It is a micrograph of the sample obtained in Example 3. It can be seen that the surface of the sample has a high roughness and the cavities have different sizes, which is beneficial to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com