Method for producing polypeptone by enzymolysis of casein as raw material

A technology for polyprotein and casein, which is applied in the comprehensive utilization field of casein, can solve problems such as restricting popularization and use, and achieves the effects of short enzymolysis time, suitable promotion and small amount of enzyme used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

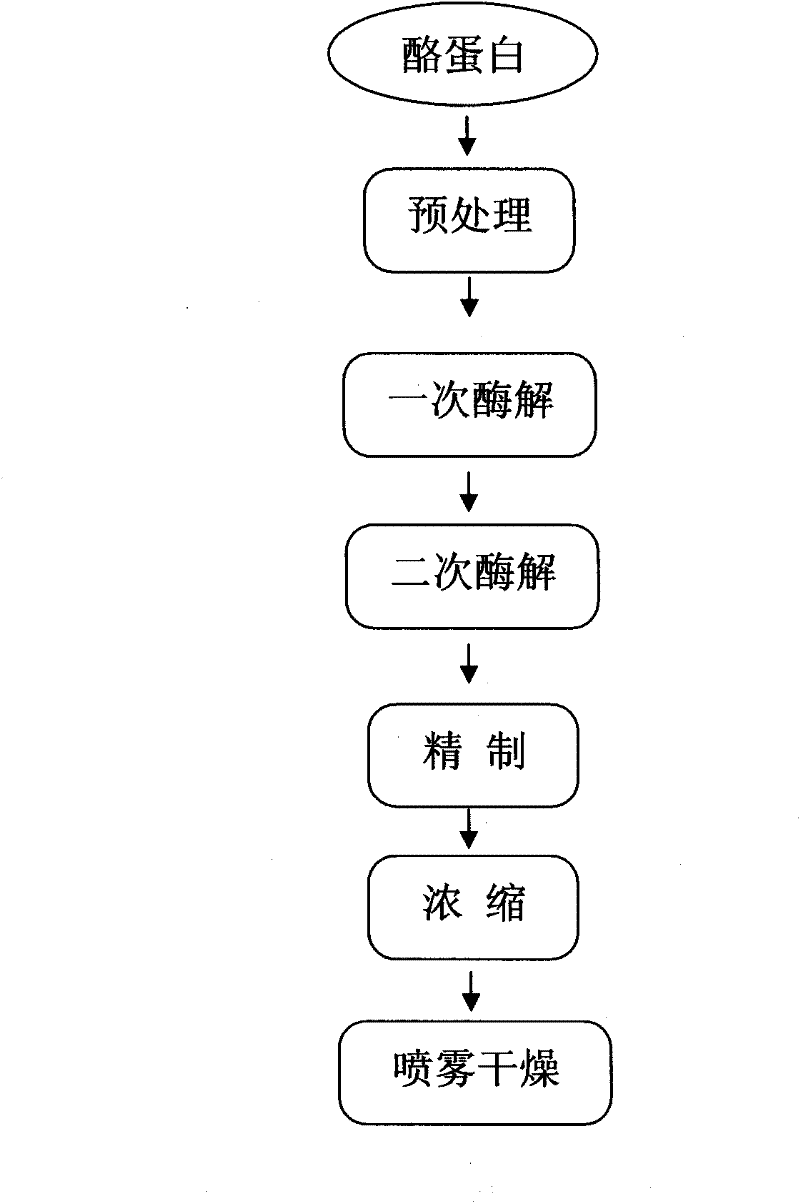

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Take 100g of casein, make a 6% solution with purified water, and add Na 2 SO 3 0.3g, stirring to dissolve, heating to 90℃ for 15min under stirring, cooling to 50℃, adjusting PH7.5 with 5% NaOH solution, adding 0.35g of 1121 type complex protease, stirring for 3h at 40℃-45℃, adjusting the system PH6 .5, at a temperature of 48℃-50℃, add 0.25g of 1001 type complex protease, stir for 2.5h, heat up to 85℃ to inactivate the enzyme for 10min, add 3.5g of diatomaceous earth, stir and absorb for 15min, filter under reduced pressure to obtain a clear filtrate, Concentrate about 250ml under reduced pressure by rotary evaporation and spray-dry to obtain 80.3g of polypeptone with a yield of 80.3%. The amino nitrogen content is determined to be 5.2%.

Embodiment 2

[0015] Example 2: Take 1kg casein, make 8% solution with pure water, add 10g Na 2 SO 3 , Stir to dissolve, heat to 100℃ for 20min under stirring, cool to 50℃, adjust PH8.0 with 5% NaOH solution, add 6.0g of 1121 compound protease, enzymolysis at 45℃-48℃ for 4.5h, adjust system Ph7.0 , Temperature 50℃-52℃, add 5.0g of 1001 complex protease, stir for 3.5h, heat up to 90℃ to inactivate the enzyme for 15min, add 80g of diatomaceous earth, stir and absorb for 20min, filter with a filter to obtain a clear transparent liquid, use evaporation It was concentrated under reduced pressure to about 2500ml, and spray-dried by pressure spray drying to obtain 825g polypeptone, the yield was 82.5%, and the amino nitrogen content was determined to be 5.9%.

Embodiment 3

[0016] Example 3: Take 100 kg of casein, make a 10% solution with pure water, and add 1.2 kg of NaHSO 3 , Stir to dissolve, heat to 110℃ for 25min under stirring, cool to 50℃, adjust PH8.5 with 20% NaOH solution, add 0.8kg of 1121 compound protease, stir for 6h at 48℃-50℃, adjust the system PH7.0, Temperature 52℃-55℃, add 0.6kg of 1001 compound protease, stir for 4.5h, heat up to 95℃, inactivate enzyme for 20min, add 15kg of diatomaceous earth, stir and absorb for 30min, filter by automatic slag filter to obtain clear and transparent filtrate Concentrate under reduced pressure with a double-effect evaporator to about 185kg, and spray-dry with a pressure spray drying tower to obtain 83.7kg of polypeptone with a yield of 83.7%. The amino nitrogen is 6.7% after determination.

[0017] The heating pretreatment of the present invention makes the helical structure of casein loose, so that the composite protease can smoothly enter the amino acid binding site of the protein, which is bene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com