A kind of preparation method of surface-enhanced Raman spectroscopy active substrate

A technology of surface-enhanced Raman and active substrates, which is applied in the process of producing decorative surface effects, the manufacture of microstructure devices, decorative arts, etc. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

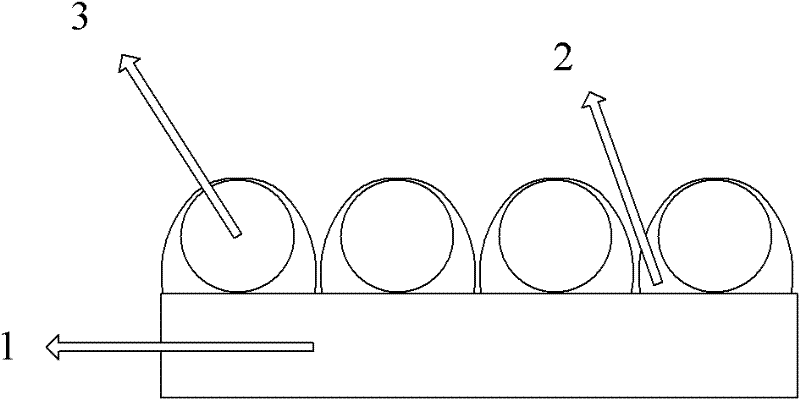

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the embodiments.

[0034] 1) According to the steps of acetone, ethanol, and three times of water, ultrasonically clean a 1cm×1cm silicon wafer, wash each solution for 15 minutes, and then use a mixed solution of ammonia water:hydrogen peroxide:three water ratios of 1:1:6 to heat and soak at 70°C. Silicon wafer 30min. Take out the silicon wafer and ultrasonicate it with water three times for 15 minutes, then dry it with nitrogen gas, and treat it with ozone plasma for 10 minutes for later use.

[0035] 2) Almost fill the 50mL beaker with water, then add 6 μl of 2% sodium lauryl sulfate solution dropwise, and let stand.

[0036] 3) Dilute 0.46 μm polystyrene microbeads purchased from sigma with ethanol at a ratio of 1:1, then drop 5 μl of the diluted solution onto the silicon wafer in step 1), and slowly immerse the silicon wafer into the silicon wafer prepared in step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com