Preparation method for jelly fish neurotensin

A technology of antihypertensive peptides and jellyfish, which is applied in the field of preparation of polypeptide mixtures, can solve the problems of poor activity preservation, low purity, and low yield of antihypertensive peptides, and achieve the effects of reduced production costs, high extraction rates, and simple operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

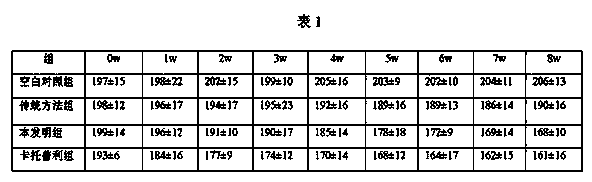

Image

Examples

Embodiment 1

[0026] Removal of various metal ions in jellyfish: First, use an ultrapure water machine to extract deionized water, which requires an impedance value of not less than 10. Mix the two according to the mass ratio of salted jellyfish to ultrapure water of 1:2, and stir for 30 Minutes; then extract deionized water from the ultrapure water machine, requiring an impedance value of not less than 15, mix the two according to the mass ratio of salted jellyfish to ultrapure water of 1:2, and stir for 30 minutes; The machine extracts deionized water, and the impedance value is required to be not less than 18. According to the mass ratio of salted jellyfish to ultrapure water of 1:1, mix the two and stir for 15 minutes.

[0027] Drain the jellyfish after removing the metal ions, put it into a tissue meat grinder and grind it; put the ground jellyfish into a homogenizer, and homogenize it at 5000r / min for 10 minutes.

[0028] Dilute the homogenized jellyfish slurry 100 times with ultrapur...

Embodiment 2

[0032] First, pre-treat the salted jellyfish to remove various metal ions in the jellyfish, and extract deionized water from the ultrapure water machine. The impedance value is required to be not less than 10. According to the quality of salted jellyfish to ultrapure water is 1:2 Mix the two and stir for 30 minutes; then extract deionized water from the ultrapure water machine, requiring an impedance value of not less than 15, mix the two according to the mass ratio of salted jellyfish to ultrapure water of 1:2, and stir 30 minutes; finally extract deionized water from the ultrapure water machine, the impedance value is required to be no less than 18, mix the two according to the mass ratio of salted jellyfish to ultrapure water of 1:1, and stir for 15 minutes.

[0033] Take out the jellyfish and drain the water, put it into the tissue meat grinder and grind it; put the ground jellyfish into the homogenizer, and homogenize it at 5000r / min for 10 minutes; the jellyfish slurry af...

Embodiment 3

[0038] First, pre-treat the salted jellyfish to remove various metal ions in the jellyfish, and extract deionized water from the ultrapure water machine. The impedance value is required to be not less than 10. According to the quality of salted jellyfish to ultrapure water is 1:2 Mix the two and stir for 30 minutes; then extract deionized water from the ultrapure water machine, requiring an impedance value of not less than 15, mix the two according to the mass ratio of salted jellyfish to ultrapure water of 1:2, and stir 30 minutes; finally extract deionized water from the ultrapure water machine, the impedance value is required to be no less than 18, mix the two according to the mass ratio of salted jellyfish to ultrapure water of 1:1, and stir for 15 minutes.

[0039] Take out the jellyfish and drain the water, put it into a tissue meat grinder and grind it; put the ground jellyfish into a homogenizer, and homogenize it at 5000r / min for 10 minutes.

[0040]Dilute the homogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com