Lithium battery negative electrode preparation method and lithium battery thereof

A lithium battery and negative electrode technology, applied in the field of batteries, can solve the problems of separation of positive and negative electrodes and separators, affecting battery life, etc., and achieve the effect of preventing reduction reaction, enhancing conductivity, and reducing battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

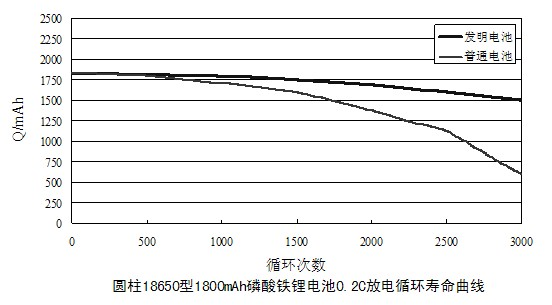

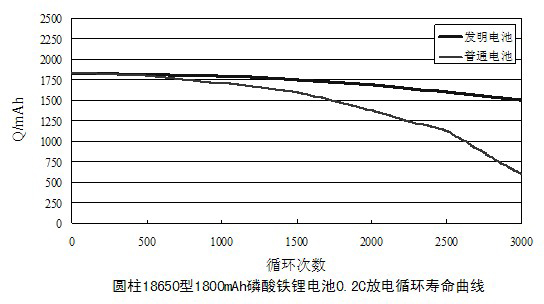

Image

Examples

Embodiment 1

[0033] Lithium battery negative electrode is prepared by the following method:

[0034] (1) Mix the negative electrode active material graphite, conductive carbon black, VGCF (nano carbon fiber), binder SBR (styrene-butadiene rubber), LA133 (water-based binder); the active material graphite, conductive carbon black, VGCF , SBR, LA133 ratio is (by weight): 80: 10: 1: 3: 6; the graphite is a spherical graphite with a particle size of 18.0-22.0 μm and a specific surface area ≤ 20.0 m 2 / g of two kinds of graphite mixed;

[0035] (2) Make a paste adhesive and apply it evenly on both sides of the copper foil;

[0036] (3) Then vacuum drying, rolling and cutting to form negative electrode sheets;

[0037] Its positive electrode is prepared by the following method:

[0038] LiFePO 4 , conductive graphite, and PVDF are mixed evenly in a weight ratio of 86:9:5, stirred into a paste, and evenly coated on both sides of the aluminum foil with a coating thickness of 16 μm. Dry under ni...

Embodiment 2

[0045] Lithium battery negative electrode is prepared by the following method:

[0046] Mix the negative electrode active material graphite, conductive carbon black, VGCF (nano carbon fiber), binder SBR (styrene-butadiene rubber), LA133 (water-based binder); the active material graphite, conductive carbon black, VGCF, SBR, The proportion of LA133 is (in parts by weight): 75:12:1.5:2:7; the graphite is spherical graphite with a particle size of 18.0-22.0 μm and a specific surface area of ≤20.0 m 2 / g of two kinds of graphite mixed;

[0047] All the other are with embodiment 1.

Embodiment 3

[0049] Lithium battery negative electrode is prepared by the following method:

[0050] Mix the negative electrode active material graphite, conductive carbon black, VGCF (nano carbon fiber), binder SBR (styrene-butadiene rubber), LA133 (water-based binder); the active material graphite, conductive carbon black, VGCF, SBR, The proportion of LA133 is (in parts by weight): 85:8:0.5:4:5; the graphite is spherical graphite with a particle size of 18.0-22.0 μm and a specific surface area of ≤20.0 m 2 / g of two kinds of graphite mixed;

[0051] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com