Preparation method of inorganic mesoporous membrane

A kind of mesoporous membrane, inorganic technology, applied in the field of preparation of inorganic mesoporous membrane, can solve the problems of inorganic film cracks, easily damaged inorganic film, etc., achieve the effect of reducing the difficulty and cost of preparation, and enriching the three-dimensional interconnected pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the inorganic mesoporous membrane of the present embodiment comprises the following steps:

[0029] Step 1: At room temperature, fully mix ethyl orthosilicate with deionized water and hydrochloric acid, and stir for 20 minutes to obtain a sol mixed solution; (hydrochloric acid acts as a catalyst and a pore-forming agent at the same time)

[0030] Step 2: Pour the obtained sol mixture into a petri dish, and transform it into a gel at room temperature to obtain a metal oxide gel;

[0031] Step 3: Repeatedly soak the gel with deionized water until the soaking solution is close to neutral, and then wash away the pore-forming agent in the metal oxide gel;

[0032] Step 4: drying the washed metal oxide gel to obtain an inorganic mesoporous membrane based on metal oxide.

[0033]

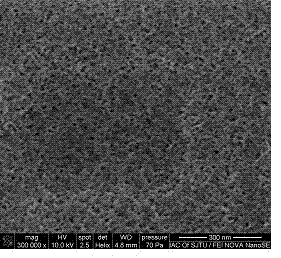

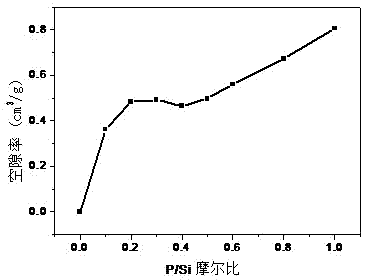

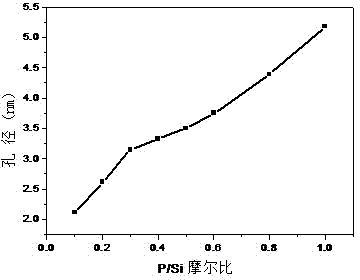

[0034] Implementation effect: The chemical composition of the inorganic mesoporous membrane prepared in this example is mainly SiO 2 ; The average pore diameter measur...

Embodiment 2

[0036] The preparation method of the inorganic mesoporous membrane of the present embodiment comprises the following steps:

[0037] Step 1: At room temperature, fully mix the metal oxide precursor with water and catalyst, and stir for 20 minutes to obtain a sol mixed solution; then slowly add the pore-forming agent to the mixed solution, and stir for 5 minutes;

[0038] Step 2: Pour the obtained sol mixture into a petri dish, and transform it into a gel at room temperature to obtain a metal oxide gel;

[0039] Step 3: Soak the gel repeatedly with a solvent until the soaking solution is close to neutral, and then wash away the pore-forming agent in the metal oxide gel;

[0040] Step 4: drying the washed metal oxide gel to obtain an inorganic mesoporous membrane based on metal oxide.

[0041]

[0042] Implementation effect: the chemical composition of the inorganic mesoporous membrane prepared in Example 2 is mainly SiO 2 ; The average pore diameter measured by nitrogen ad...

Embodiment 4~23

[0044]The preparation method of the inorganic mesoporous membrane in Examples 4-23 comprises the following steps:

[0045] Step 1: At room temperature, fully mix the metal oxide precursor with water, catalyst, and pore-forming agent, and stir for 20 minutes to obtain a sol mixed solution;

[0046] The second step: Pour the obtained sol mixture into a petri dish, and transform it into a gel at room temperature to obtain a metal oxide gel; After heat preservation at 120°C for 24 hours, cool to room temperature; (the mechanical strength of the inorganic mesoporous membrane obtained after heat treatment is better than that obtained without heat treatment)

[0047] Step 3: Soak the gel repeatedly with a solvent until the soaking solution is close to neutral, and then wash away the pore-forming agent in the metal oxide gel;

[0048] Step 4: drying the washed metal oxide gel to obtain an inorganic mesoporous membrane based on metal oxide.

[0049] The specific material used in each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com