Water processing method

A water treatment and water treatment technology, applied in the direction of osmosis/dialysis water/sewage treatment, etc., can solve the problems of increasing the frequency of chemical cleaning, reducing production efficiency, increasing costs, etc., achieving obvious industrial implementation feasibility, improving effect, reducing The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

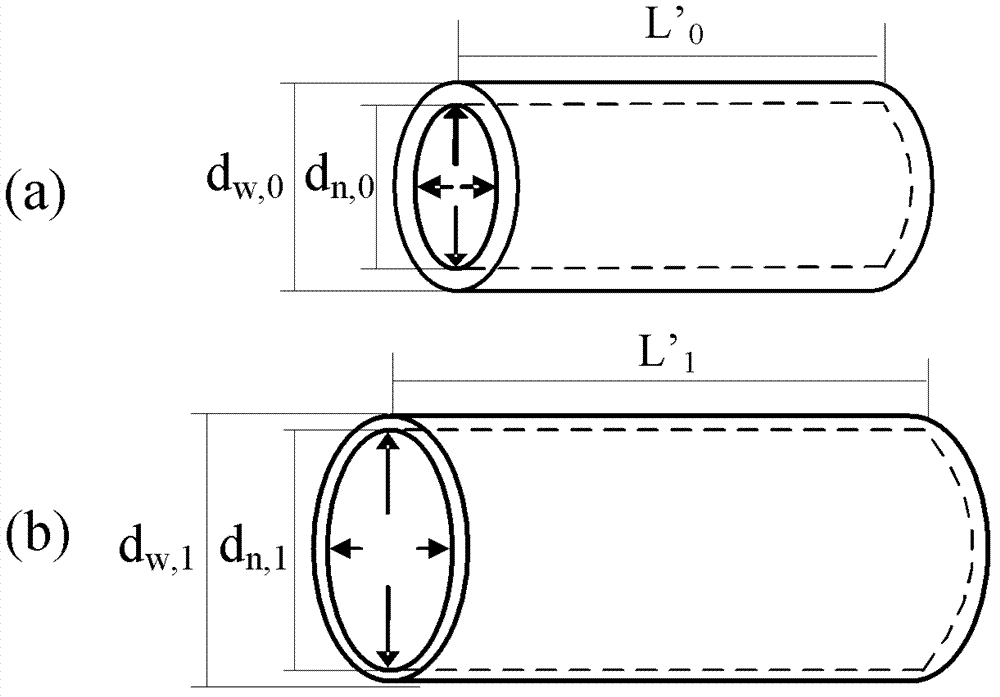

[0019] Use inorganic powder (particle size distribution between 1-30μm, of which 87.16% of the pores are concentrated between 4-25μm) to disperse in water to form a suspension as the filtered stock solution to investigate polyurethane elastic hollow fiber membranes (pore size distribution Between 0.08-0.28μm, of which 76.36% of the pores are concentrated between 0.18-0.22μm) used under external pressure conditions, and the flux recovery after backwashing under internal pressure conditions.

[0020] The test conditions are as follows:

[0021] The polyurethane-based elastic hollow fiber membrane is cast into a U-shaped groove submerged membrane module, and the suction filtration method is used for external pressure filtration. The inner membrane area of the module is about 8.64×10 -2 m 2 ;

[0022] The concentration of the filtered stock solution is 5‰;

[0023] The test process is:

[0024] (1) Test the pure water flux of the hollow fiber membrane, the test pressure is 0...

Embodiment 2

[0029] Using the suspension prepared from the inorganic powder in Example 1 with a concentration of 0.5‰, the retention performance of the elastic hollow fiber membrane mentioned in Example 1 was investigated.

[0030] The testing process is as follows:

[0031] The polyurethane-based elastic hollow fiber membrane is cast into a U-shaped module, and the container storage method is used for external pressure filtration. The inner membrane area of the module is about 8.64×10 -2 m 2 ; The test pressure is 0.1MPa, the test time is 120min, and the filtrate is taken every 20min on average to test its turbidity and compare with the turbidity of the original solution. Continuous test for 120min, the average flux is 69.68L / (m 2 h), the turbidity of the stock solution is 32.1ntu, while the average turbidity of the filtrate is 0.154. (Far lower than the drinking water turbidity standard (1ntu) in the "Drinking Water Sanitation Standard" jointly issued by the National Standards Commi...

Embodiment 3

[0033] Utilize the suspension liquid that is made into with the inorganic powder in Example 1, concentration is 2 ‰, investigate the retention performance of the elastic hollow fiber membrane mentioned in the same example 1 and the recovery of the water flux of the hollow fiber membrane after backwashing Rate.

[0034] The testing process is as follows:

[0035] The polyurethane-based elastic hollow fiber membrane is cast into a U-shaped module, and the container storage method is used for external pressure filtration. The inner membrane area of the module is about 8.64×10 -2 m 2 ;

[0036] The test pressure is 0.1MPa, and the test time is 140 minutes. Take the filtrate every 20 minutes to test its turbidity, and compare it with the turbidity of the original solution.

[0037] (1) Using pure water, under internal pressure conditions, the initial transmembrane pressure difference of the membrane is measured to be 0.06MPa.

[0038] (2) External pressure conditions, the tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com