A polyphenol functionalized composite membrane with a "sandwich" sandwich structure separation layer and its preparation method

A sandwich structure, polyphenolic compound technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane, etc., can solve the problems of high operating pressure, achieve the effects of increased stability, improved antifouling performance, and excellent retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

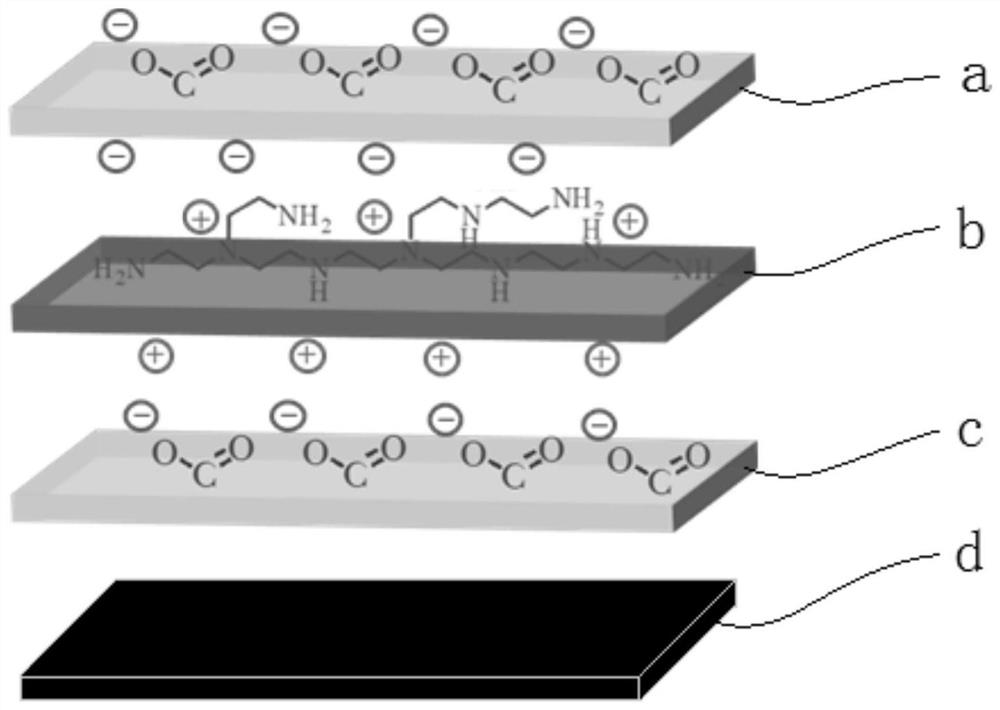

[0034] DETAILED DESCRIPTION OF THE INVENTION: The present embodiment has a polyphenol functionalized composite film having a "sandwich" sandwich structure separation layer consists of a base film and a separation layer; the separation layer is deposited on the surface of the base film; the separation layer is from two polyphenols / The oxidant composite layer and a polyphenol / polyculture composite layer are constituted; the polyphenol / polyculture composite layer is disposed between the two polyphenol / oxidant composite layers, the substrate film as a ceramic-based porous film material or high Molecular-based porous film material, the pore diameter of the base film is 0.2 to 0.45 μm, the thickness is 100 to 150 μm, and the porosity is 60 to 80%.

[0035] The principles and beneficial effects of this embodiment are:

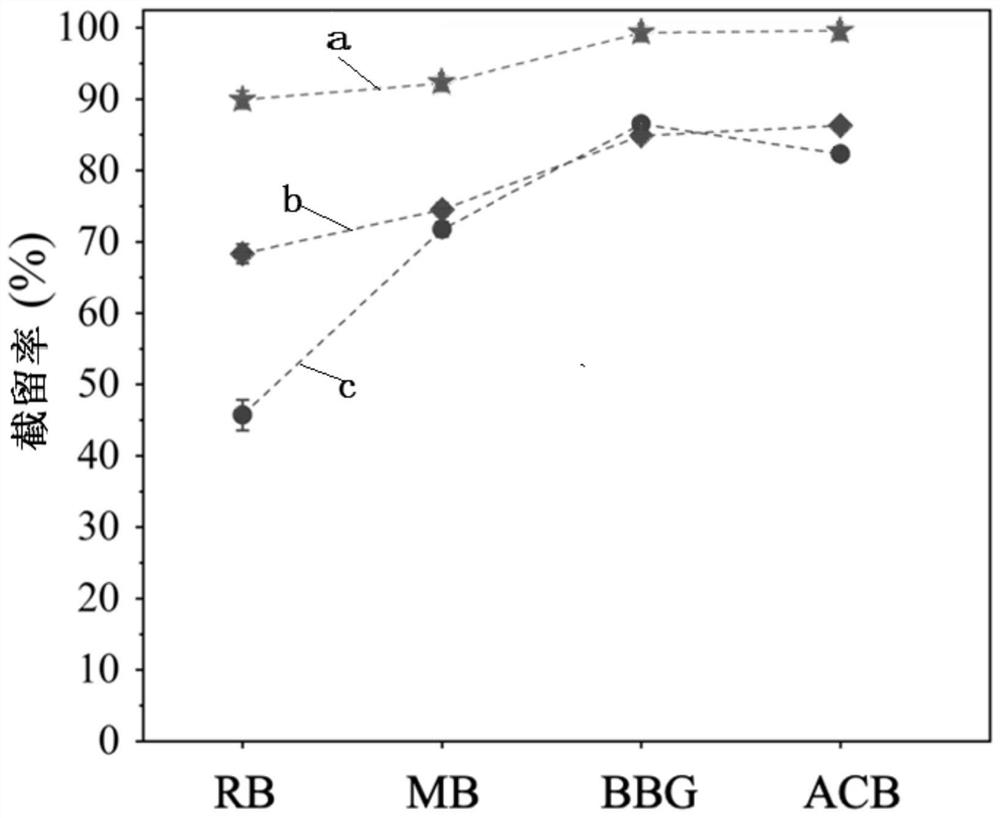

[0036] 1, the present embodiment has a "sandwich" sandwich structure separation layer of the velochemical function group in the separation layer of the separation...

specific Embodiment approach 2

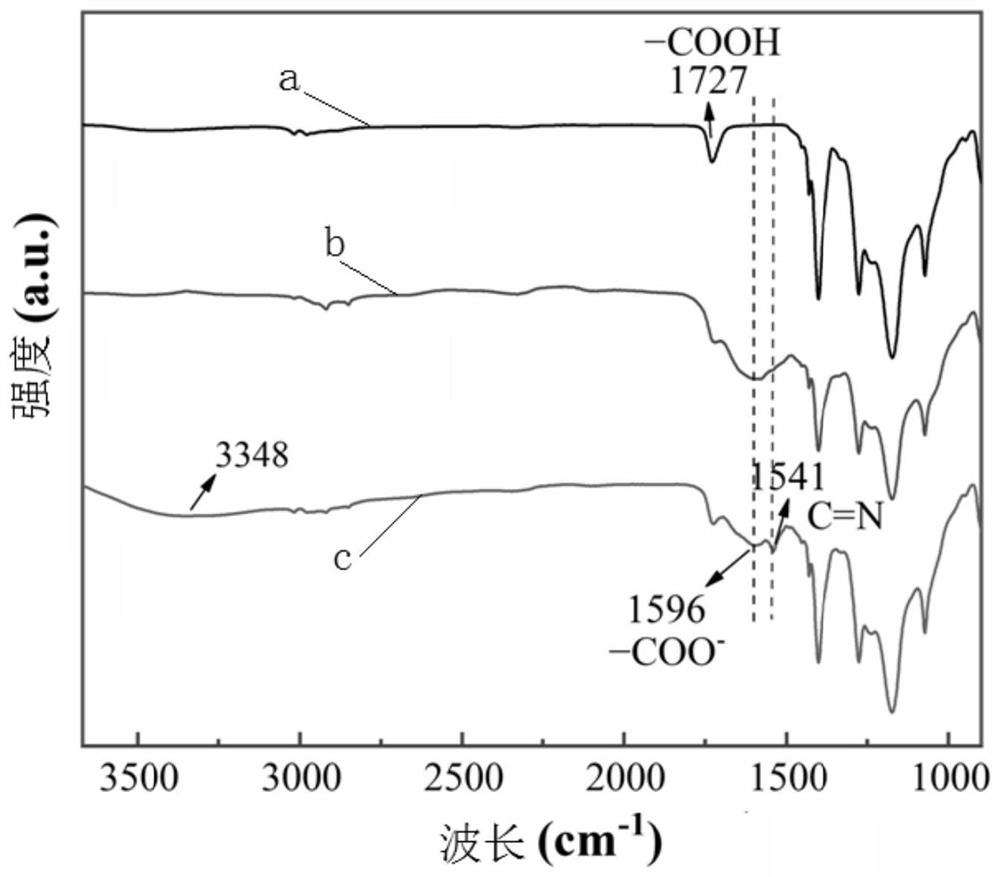

[0041] DETAILED DESCRIPTION OF THE INVENTION Different: The present embodiment differs from the specific embodiment that the polyphenol / oxidant composite layer is complicated by a polyphenol compound and an oxidant; a polyphenol compound is a dopamine, a historine, a table, and a table. The table, the table did not eat the tea ulirate, the paraceins did not eat acid ester, did not eat acid, parasite, phyllol or tanninic acid; the oxidant was sodium uretic or ammonium sulfate.

specific Embodiment approach 3

[0042] BEST MODE FOR CARRYING OUT THE INVENTION The present embodiment is different from that of the particular embodiment: the polyphenol / polymented electrolyte composite layer is composed of polyphenol compounds and polymented electrolytes; polyphenol compounds are dopamine, historia, The table did not eat the tea, the table did not eat the tea catechin did not eat acid ester, the paraceins did not eat acid ester, no food acid, parasite, edeniphenol or tanning acid; polycore electrolyte is a polyino compound; polyino compound Polyethyleneimine or chitosan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com