A kind of sewage treatment and recycling equipment and method

A technology for sewage treatment and equipment, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Achieve the effect of reducing energy consumption, reducing membrane area and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

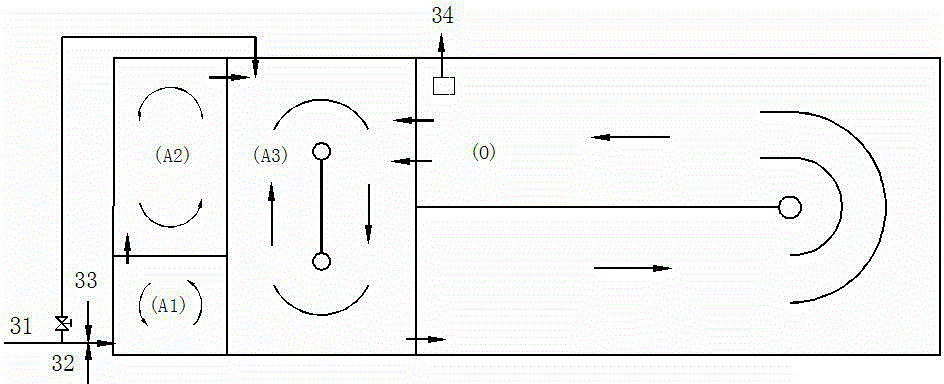

[0043] Example 1 3AO biochemical reaction pool

[0044] like figure 1 As shown, a 3AO biochemical reaction pool is composed of the first anoxic pool A1, the anaerobic pool A2, the second anoxic pool A3 and the aerobic pool O, and the four pools are respectively equipped with agitators and flowmakers , the first anoxic pool A1, the anaerobic pool A2 and the second anoxic pool A3 are connected end to end in turn, the aerobic pool O adopts an oxidation ditch form, and its end is connected with the second anoxic pool A3, and part of the sewage is in The end of the aerobic pool flows back to the A3 pool, and the first anoxic pool A1 is provided with a water inlet. After the pretreated sewage 31 is mixed with the return concentrated liquid 33 and / or the return sludge 32, it enters the first anoxic pool through the water inlet. Pool A1; the aerobic pool is provided with a vent, and the end of the aerobic pool O is also provided with a water outlet, and the biochemically treated sewa...

Embodiment 2

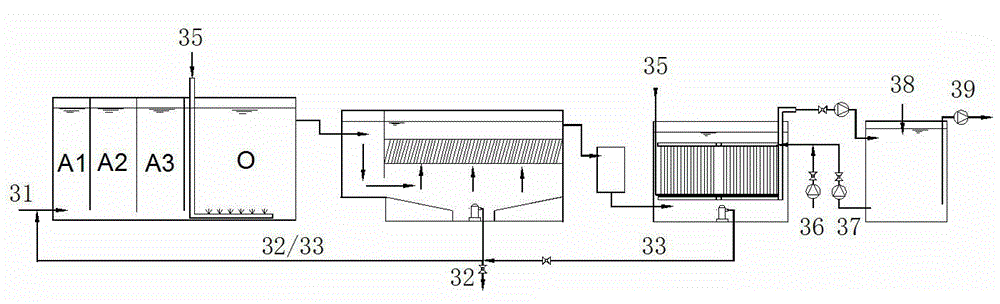

[0046] Example 2 Sewage treatment system

[0047] like figure 2 As shown, a sewage treatment and recycling equipment includes a biochemical reaction tank, a high-efficiency sedimentation tank and a membrane filtration unit. Described biochemical reaction pond is the 3AO biochemical reaction pond described in embodiment 1

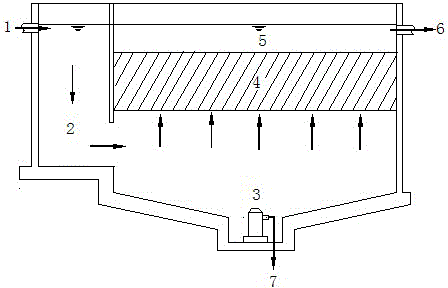

[0048] The high-efficiency sedimentation tank such as image 3 As shown, it includes water inlet pipe 1, buffer zone 2, sludge discharge pump 3, inclined pipe or inclined plate 4, clear water area 5, outlet pipe 6 and sludge discharge pipe 7; after the sewage enters the sedimentation tank, it first passes through the buffer zone, and then the sludge Under the action of the inclined pipe or inclined plate 4, it settles quickly and is discharged through the mud discharge pump 3 and the mud discharge pipe 7, and the clean water in the clean water area 5 is discharged through the outlet pipe 6 and enters the membrane filtration unit. The bottom of the sedime...

Embodiment 3

[0052] A sewage treatment and recycling process, using the equipment described in Example 2, using a combination of biochemical treatment, high-efficiency sedimentation and membrane filtration, the sewage after biochemical treatment first enters a high-efficiency sedimentation tank to settle out most of the sludge, followed by membrane filtration. The specific operation steps are (such as Figure 6 shown):

[0053] (1) The new sewage from the pretreatment system is mixed with the reflux concentrate and / or reflux sludge and enters the first anoxic pool A1 for anoxic denitrification and denitrification reaction;

[0054] (2) The sewage enters the anaerobic pond (A2) from the first anoxic pond (A1). Under the anaerobic environment, the phosphorus accumulating bacteria in the sewage release phosphorus to generate energy to absorb and rapidly degrade organic matter, and convert it into poly-β-hydroxy Butyric acid is stored;

[0055] (3) The sewage enters the second anoxic pond (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com