Nitrate nitrogen removal method and device for said method

A nitrate nitrogen and denitrification technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problem of reduced denitrification speed, insufficient denitrification treatment, and difficulty in tracking drainage. Temperature, water volume, pollutant concentration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

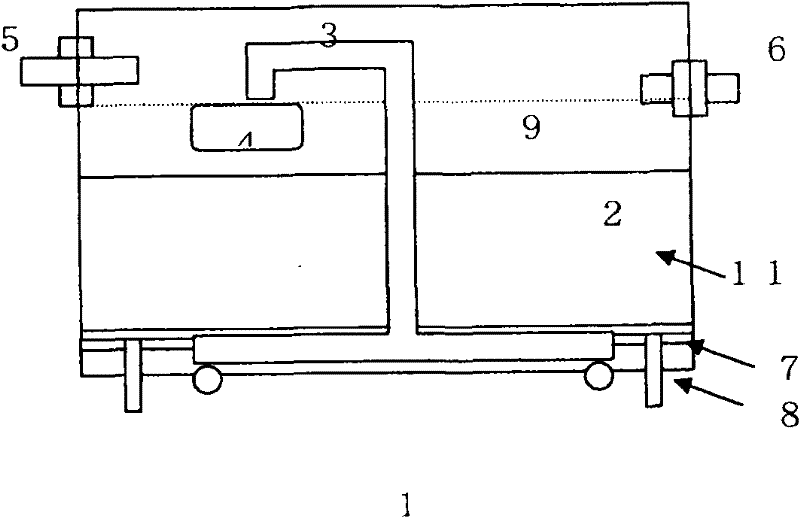

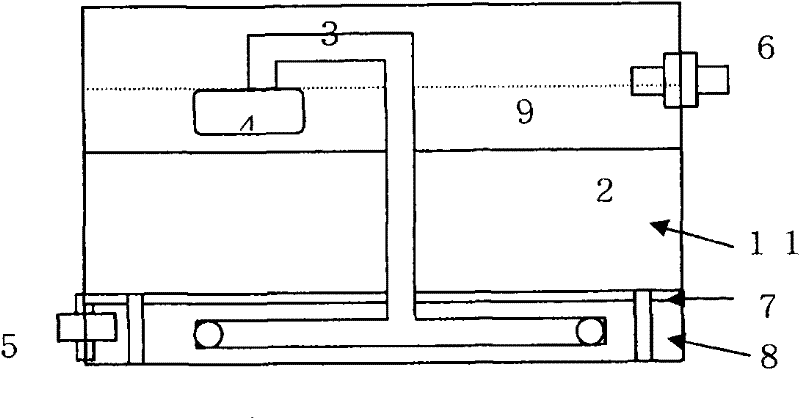

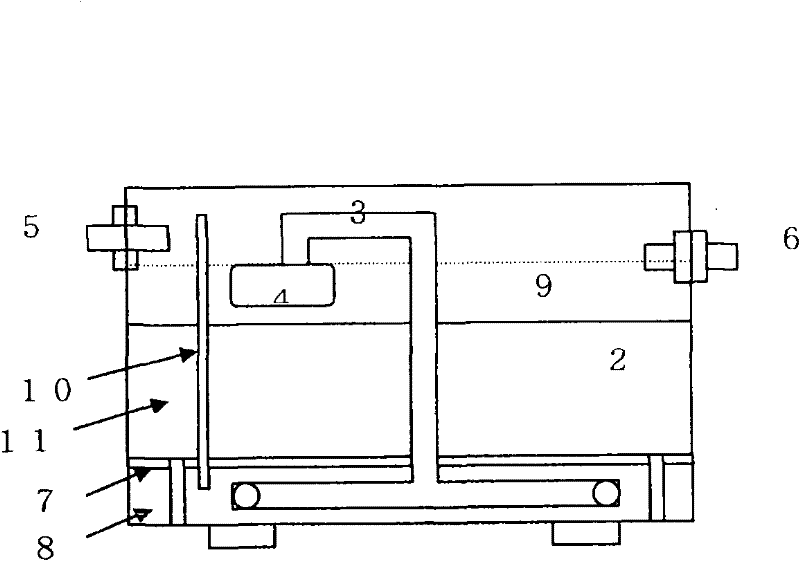

[0084] use figure 1 The shown nitrate nitrogen removal device 1 treats nitrate nitrogen while the drainage is circulating. First, make the drain flowing into the device from the water inlet 5 fill up to a predetermined liquid level (height of the water outlet 6). Afterwards, the circulating pump 4 is operated to circulate the upper layer water 9 from above to below through the pipe 3, and flow out from the lower square outlet. The outflowing drainage uniformly infiltrates the denitrification material filling layer 2 filled on the bottom plate having open holes, and is supplied for denitrification. Thereafter, the denitrified treated water is discharged from the water outlet 6 in an amount corresponding to the flow rate of the wastewater flowing in from the water inlet 5 .

[0085] In this embodiment, in a cuboid treatment tank with a capacity of 100 L, 40 kg of sulfur and calcium carbonate mixed compositions (filling density 1.2) with a particle diameter of 5 to 20 mm were ...

Embodiment 2

[0088] 3 kg of a denitrification material comprising an inorganic material obtained by making a sulfur molten mixture containing 50 parts by weight of sulfur and 50 parts by weight of calcium carbonate into pellets with a diameter of 5 to 20 mm was filled into the treatment tank. This denitrification material was cultured for 3 weeks with denitrification bacteria contained in soil collected from a green onion field.

[0089] use Figure 5 The nitrate nitrogen removal unit shown. The treatment tank is a cylinder with a diameter of 10 cm and a length of 70 cm. The tank volume of the preliminary tank 16 is set to about 20 L, the tank volume of the treatment tank is set to about 5 L, and the temperature of the preliminary tank and the treatment tank is set at 30° C. As drainage, artificial drainage with a nitrate nitrogen concentration of 200 mg / L was used by mixing OK-F-2 manufactured by Otsuka Chemical Co., Ltd. with tap water. The artificial drainage was passed continuously a...

Embodiment 3

[0092] used Figure 5 The nitrate nitrogen removal unit shown. By mixing OK-F-2 produced by Otsuka Chemical and tap water to prepare artificial drainage with a nitrate nitrogen concentration of 50mg / L, at a drainage temperature of 5°C and a drainage speed of 1L / hr, the water was continuously passed for 12 hours, and the circulation volume was studied. When the concentration of nitrate nitrogen at the outlet of the treatment tank after 12 hours was 10 L / hr or 0, the circulation rate was 5 mg / L at 0 and 2 mg / L at 10 L / hr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com