Process for refining chemical grade isoprene into polymer grade isoprene

An isoprene, polymerization-grade technology, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems that the dissolution and dispersion properties of polymerization inhibitors are not ideal, and achieve the effect of improving comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

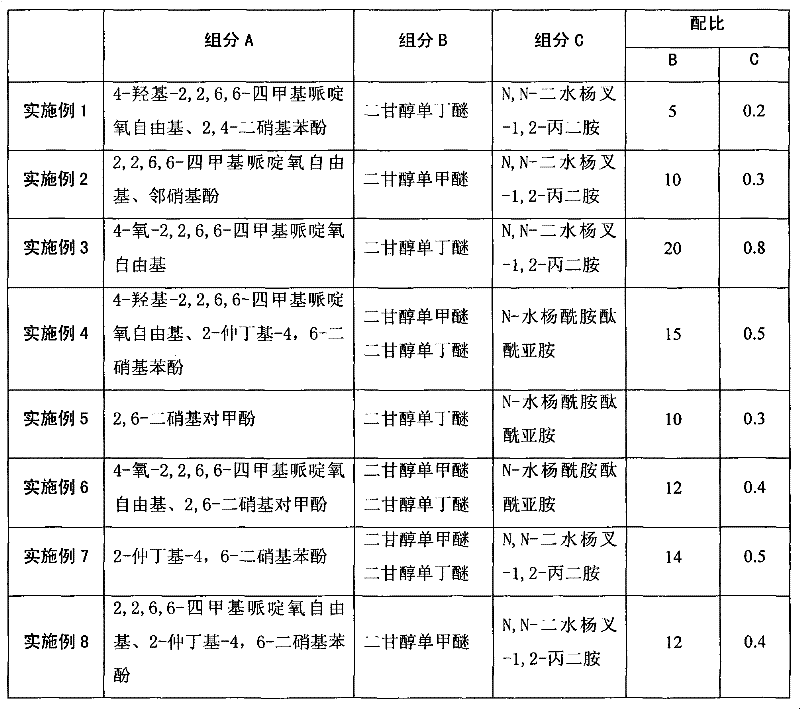

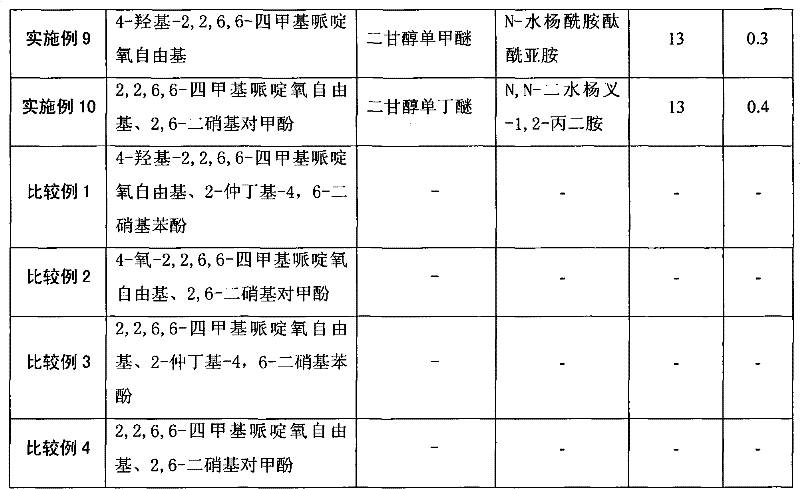

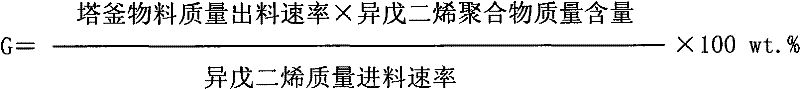

[0027] Components A, B and C of the polymerization inhibitor each get a suitable compound, put into the solvent dimethylformamide according to the required amount, and be stirred until completely dissolved to prepare a concentration of 50wt.% (with the total amount of all components) The polymerization inhibitor solution of measuring meter) is standby. See Table 1 for the components A, B and C used in each embodiment and their mutual proportions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com