High-efficiency fluorine-free desulfurization refining slag system for low-carbon aluminum-killed steel

A low-carbon aluminum-killed steel and slag refining technology, applied in the field of steelmaking, can solve the problems of shortening the service life of the ladle, accelerating the erosion of the ladle lining, harmful to human health, etc., and achieves the effect of reducing the amount of slag, improving the desulfurization effect, and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

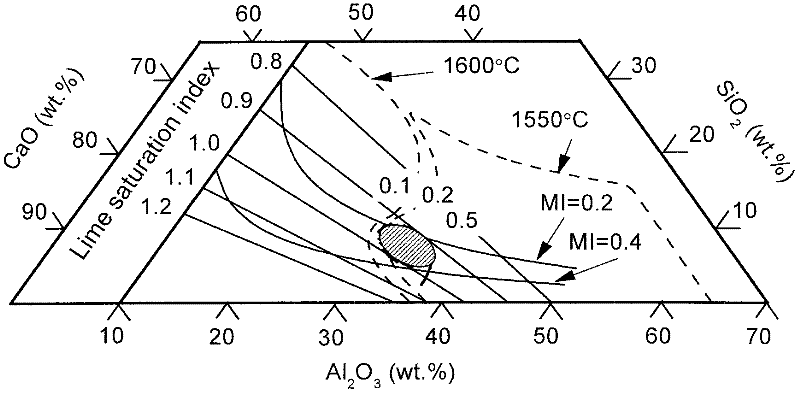

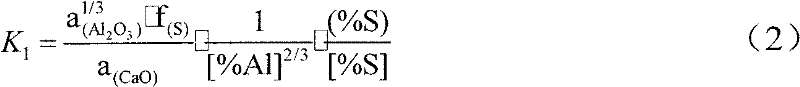

Method used

Image

Examples

Embodiment 1

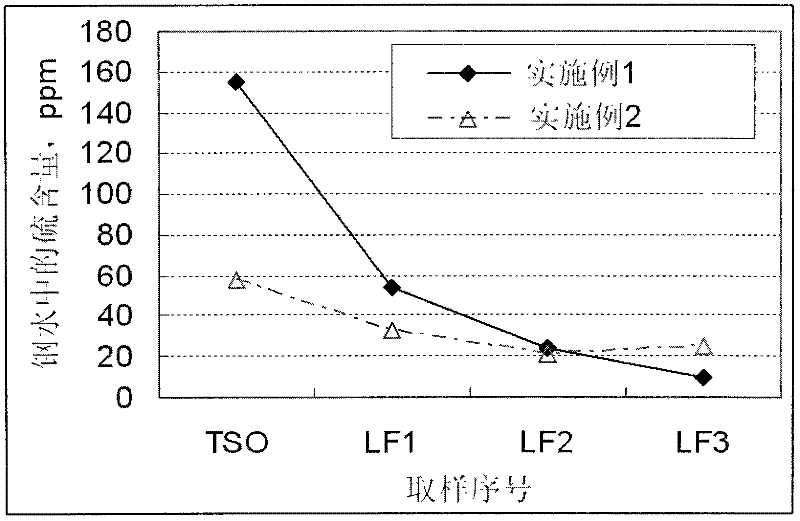

[0036]Using the refining slag provided by the invention, experiments are carried out on the SPA-H steel type, with a ladle of 180 tons.

[0037] 1) Converter blowing end point [S]=0.0155%, [O]=990ppm, temperature T=1636°C. Converter tapping strictly prevents slag, adding 400kg of aluminum particles and 610kg of lime during tapping, and adding 30kg of aluminum particles on the slag surface at the end of tapping.

[0038] 2) When LF arrives at the station, 445kg of lime is added at one time, and the slag is completed within about 5 minutes. After slag melting, LF1 molten steel samples were taken, [S]=0.0054%, [Als]=0.0529% in molten steel. The flow rate of bottom blowing gas in ladle is 800N1 / min*2 during slag melting, and the flow rate of bottom blowing gas in heating stage is 350Nl / min*2. After refining for 15 minutes, [S]=0.0024% and [Als]=0.041% in molten steel. At the end of refining, molten steel [S]=0.001%, [Als]=0.041%, temperature T=1580°C. Refining time is 40min, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com