Impulse characteristic simulation test device and method of grounding device

A grounding device and simulation test technology, which is applied in the direction of test ship construction and dielectric strength testing, can solve the problems of not being able to obtain the impact characteristics of the grounding device, not being able to better simulate the soil discharge process, and the amplitude of the impact current is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

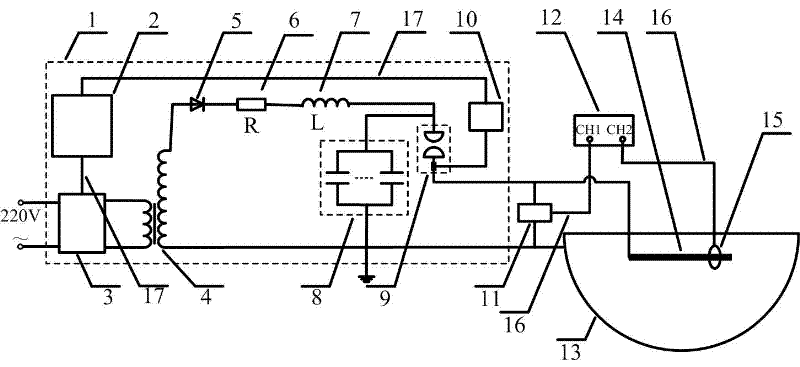

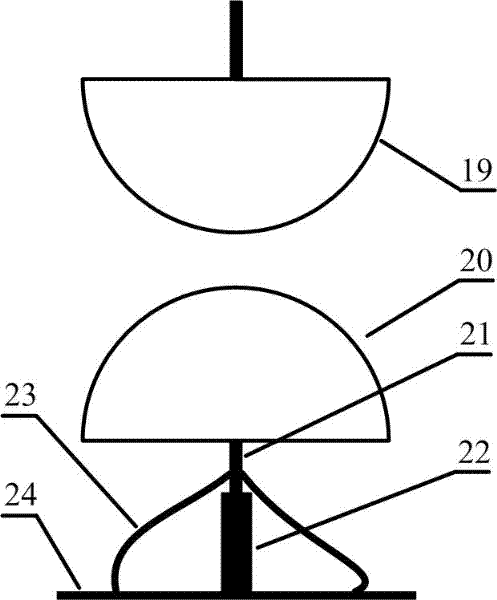

[0055] Such as figure 1 ~ As shown in 5, a simulation test device for the impulse characteristics of a grounding device mainly includes an impulse current generator 1, a hemispherical test tank 13, an analog grounding device 14, a core-through current sensor 15, an impulse voltage divider 11, a broadband digital Oscilloscope 12 and coaxial shielded cable 16 and so on.

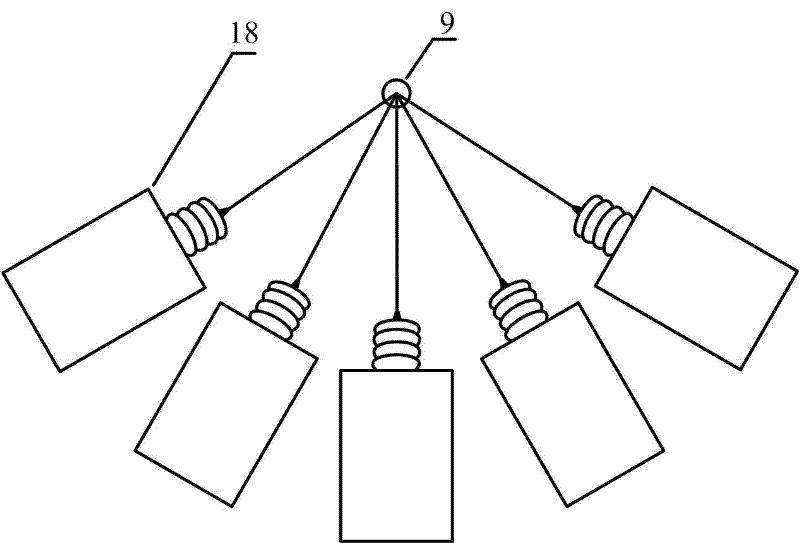

[0056] The impulse current generator 1 is a commercially available module, and the instantaneous amplitude is 8 ~ 200kA adjustable, wave front time 1.2 ~ 20 variable, wave tail time is 20 ~ 1000 Variable double exponential current wave. Impulse current generator 1 mainly includes: intelligent control system 2, voltage regulator 3, step-up transformer 4, silicon stack 5, wave modulation resistor 6, wave modulation inductor 7, pulse capacitor bank 8, pneumatic ignition ball gap 9, air compression Machine 10. The intelligent control system 2 is respectively connected with the voltage regulator 3 and the ...

Embodiment 2

[0064] A simulation test device for the impact characteristics of a grounding device is the same as in Embodiment 1, wherein: the pulse capacitor bank 8 is composed of 12 pulse capacitors of 30 μF connected in parallel, and every 3 pulse capacitors are connected in parallel to form a group. The hemispherical test tank 13 is a hemispherical shell with a diameter of 5 m and a steel plate whose outer wall is 2 mm thick. The non-magnetic skeleton 25 has an inner diameter of 5 cm, an outer diameter of 6 cm, and a cross-sectional diameter of 2 cm. The copper coil 27 is evenly wound on the circular non-magnetic skeleton 25 by a copper enameled wire with a wire diameter of 1.12mm, and the number of turns is 700 turns. A polymer insulating shell 26 with a thickness of 1 cm is cast on the surface of the core-through current sensor 15 .

Embodiment 3

[0066] A simulation test device for the impact characteristics of a grounding device is the same as in Embodiment 1, wherein: the pulse capacitor bank 8 is composed of 20 pulse capacitors of 100 μF connected in parallel, wherein every 2 pulse capacitors are connected in parallel to form a group. The hemispherical test tank 13 is a hemispherical shell with a diameter of 10 m and an outer wall made of a steel plate with a thickness of 3 mm. The non-magnetic skeleton 25 has an inner diameter of 10 cm, an outer diameter of 12 cm, and a cross-sectional diameter of 2 cm. The copper coil 27 is evenly wound on the circular non-magnetic skeleton 25 by a copper enameled wire with a wire diameter of 1.67mm, and the number of turns is 1000 turns. The surface of the core-through current sensor 15 is cast with a polymer insulating shell 26 with a thickness of 2 cm. The power supply of the broadband digital oscilloscope 12 is an offline UPS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com