Milk cow Streptococcus uberis subunit vaccine GapC protein, and preparation method and application thereof

A subunit vaccine, cow mastitis technology, applied in the field of bioengineering, can solve the problem of not being able to significantly reduce mastitis, and achieve broad-spectrum protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The construction of embodiment 1 genetic engineering recombinant bacterium pQE-30-GapC / XL-1-Blue and the preparation of bovine streptococcus GapC protein subunit vaccine

[0029] (1) Preparation of the GapC gene of the bovine Streptococcus dysgalactiae subunit vaccine.

[0030] DNA extraction: Take 1.5 mL culture of Streptococcus dysgalactiae, such as LS0312 strain, centrifuge at 10,000 rpm for 2 min; add 567 μL TE to the precipitate, and pipette repeatedly. Then add 30 μl 10% SDS and 3 μl 20 mg / mL Proteinase K, mix well, and bathe in 37°C water for 1 hour; add 100 μl 5M NaCl, mix well, then add 80 μl CTAB / NaCl, mix well. Water bath at 65°C for 10 minutes; add an equal volume of chloroform / isoamyl alcohol, mix well, centrifuge at 12000rpm for 4-5min, transfer the supernatant to a new tube; add an equal volume of phenol / chloroform / isoamyl alcohol, mix well, and centrifuge at 12000rpm 5min, transfer the supernatant to a new tube; add 0.6 volume of isopropanol, mix lightl...

Embodiment 2

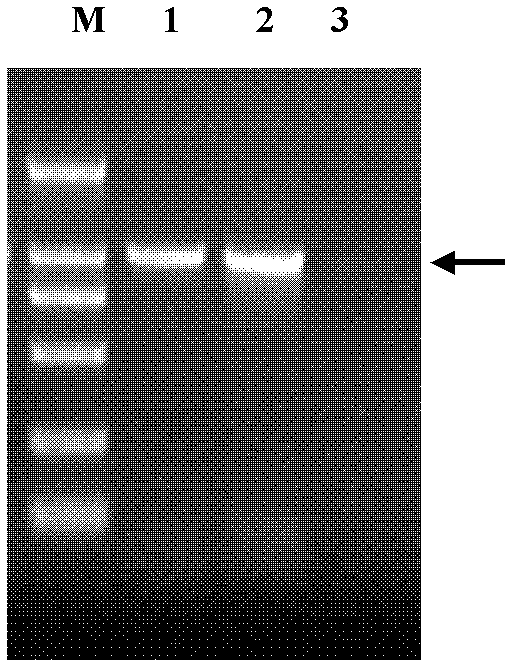

[0039] Example 2: Induced expression of recombinant bacteria pQE-30-GapC and purification of GapC protein

[0040] Inoculate 100 μL of pQE-30-GapC recombinant bacteria into 10 mL of LB medium containing 100 μg / mL ampicillin, culture at 37 ° C, when OD600 is about 0.5, aspirate 1 mL of the culture and place it in a 1.5 mL eppendorf tube. Add 100 mM inducer IPTG to a final concentration of 1 mM, and continue to culture with vigorous shaking for 6 h. Aspirate 1 mL of the bacterial solution every 1 h, centrifuge at 10,000 rpm, discard the supernatant, add 90 μL of 1× loading buffer and 10 mL of 1M DTT to the pellet, boil for 5 min, and take 15 μL for SDS-PAGE. see Figure 4 . The QIAexpressionistTM protein purification system was used for purification. Take 5 mL of the overnight cultured bacterial liquid in 0.5 L of LB liquid medium containing 50 μg / mL ampicillin, culture at 37°C for 3 h with shaking, add IPTG to a final concentration of 1 mmol / L and continue to culture for 4 h...

Embodiment 3

[0042] Embodiment 3: the fermentation culture condition optimization of engineering bacterium

[0043] (1) TR-GapC engineering bacteria

[0044] Preparation of Engineering Bacteria Seed Solution

[0045] Dissolve TR-GapC engineered bacteria, streak and inoculate them in LB solid medium containing Amp resistance, and culture at 37°C for 24 hours; then pick well-growing single colonies and inoculate them in 3 mL of LB liquid culture medium containing Amp resistance Incubate in a basal test tube at 37°C and 190rpm for 16 hours, use the sterilized basal seed medium as a blank control, measure the OD 600 of each bacterial solution, and when the OD 600 of the bacterial solution is between 1.3 and 1.5, it is regarded as a first-class seed. Take the first-grade seeds, inoculate them in LB liquid medium, and culture them at 37°C and 190rpm for 16 hours. After inspection, they are pure and stored at 2-8°C. They will be used as the second-grade seeds for experiments such as optimization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com