Method for extracting and purifying lycoris radiata lectin from lycoris radiata bulbs and lycoris radiata lectin produced by method

A technology of lycoris bulbs and lectins, which is applied in the field of lycoris lectins, can solve the problems of low product quality and achieve the effect of leaping yield, high yield and improved extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

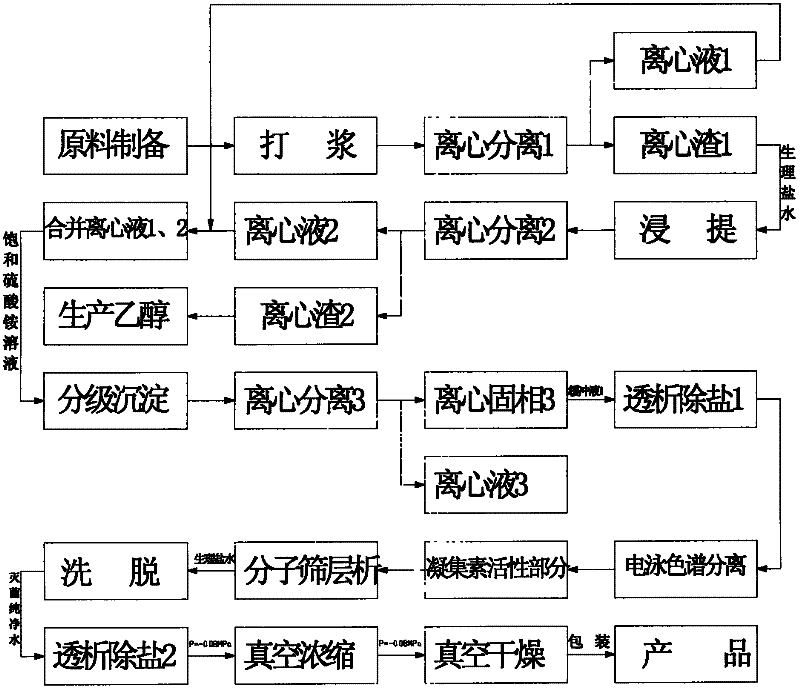

Method used

Image

Examples

example 1

[0052] (1). Raw material preparation: 11.2Kg of freshly excavated Lycoris bulbs, 1.1Kg of fibrous roots, silt, and sundries are removed, and 10.0Kg of Lycoris bulbs are left. The content of Lycoris lectin is 0.15% after testing.

[0053] (2). Beating: the fresh raw material pieces are pulverized and beaten by a pulverizer to obtain 10Kg of pulpy raw materials;

[0054] (3). Centrifugation for the first time: Separating the pulpy raw material with a centrifuge at 3500 rpm to obtain centrifuged liquid 1 and centrifuged solid phase 1, which are respectively 6.0Kg for liquid and 4.0Kg for solid phase;

[0055] (4). Enzymatic extraction;

[0056] (5). The second centrifugation: Add the centrifugal solid phase 1 to 8Kg of physiological saline, which contains 0.05ml / l of plant compound enzyme, the concentration of plant compound enzyme is 105000u / ml, the stirring speed is 50rpm, and the temperature is normal temperature. Extracted for 2 hours, centrifuged at 3500rpm in a tubular cen...

example 2

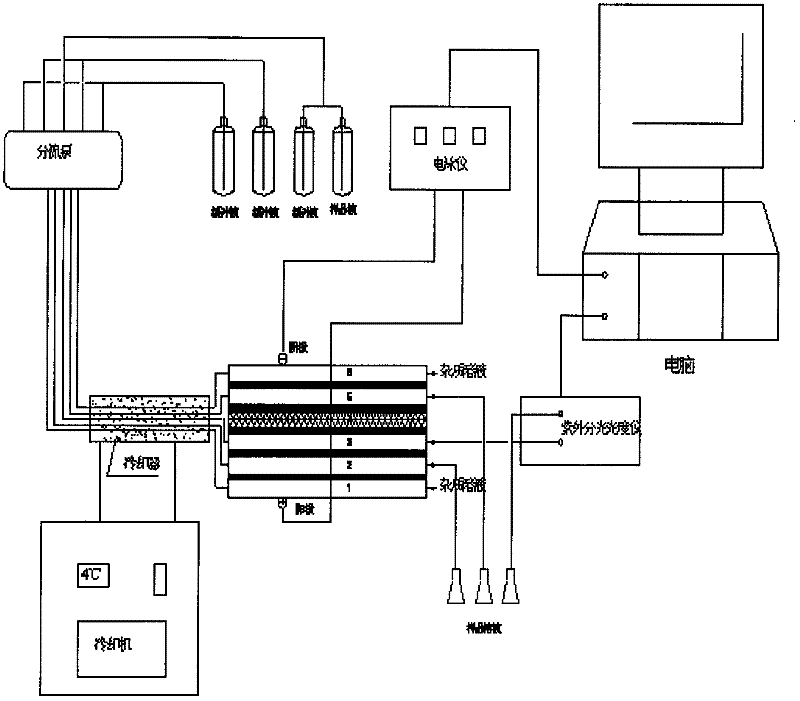

[0076] Take 5Kg of lycoris cadmium powder, the content of Lycoris lectin is 0.4% after testing, use 45Kg of normal saline 9 times the weight of dry powder to extract three times, the ratio of normal saline for three extractions is 5:3:1, normal saline Contain plant complex enzyme 0.05ml / l in it, the concentration of plant compound enzyme is 105000u / ml (leaching time is 4-5 hours, extraction speed is 50rpm), each time through tubular centrifuge 3500rpm centrifugal filtration, get clear liquid and slag, combined clear liquid, add ammonium sulfate solution, take the saturation degree of ammonium sulfate at 30%-70% and pass through tubular centrifuge 3500rpm centrifugal filtration, the obtained lycoris agglutinin crude product (slag) is put into the dialysis bag, Dialyze with pure water to desalinate until no sulfate ions can be detected with barium chloride solution as the end point of dialysis to obtain a sample solution, dissolve the crude Lycoris agglutinin in 0.02mol / L NaAC-HA...

example 3

[0080] (1). Raw material preparation: 56Kg of freshly excavated Lycoris bulbs, remove 6Kg of fibrous roots, silt, and sundries, leaving 50.0Kg of Lycoris bulbs, the content of Lycoris lectin is 0.14% after testing,

[0081] (2). Beating: the fresh raw material pieces are pulverized and beaten by a pulverizer to obtain 50Kg of pulpy raw materials;

[0082] (3). Centrifugation for the first time: Separating the pulpy raw material with a centrifuge at 3500 rpm to obtain centrifuged liquid 1 and centrifuged solid phase 1, which are respectively 30.0Kg for liquid and 20.0Kg for solid phase;

[0083] (4). Enzymatic extraction;

[0084] (5). The second centrifugation: add the centrifugal solid phase 1 to 40Kg of physiological saline, which contains 0.05ml / l of plant compound enzyme, the concentration of plant compound enzyme is 105000u / ml, the stirring speed is 50rpm, and the temperature is normal temperature. Extracted for 2 hours, centrifuged at 3500rpm in a tubular centrifuge to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com