Red divalent bismuth ion doping calcium phosphate fluorescent material and preparation method thereof

A technology of red fluorescence and bismuth ions, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., to achieve good thermal quenching resistance and shorten the fluorescence lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

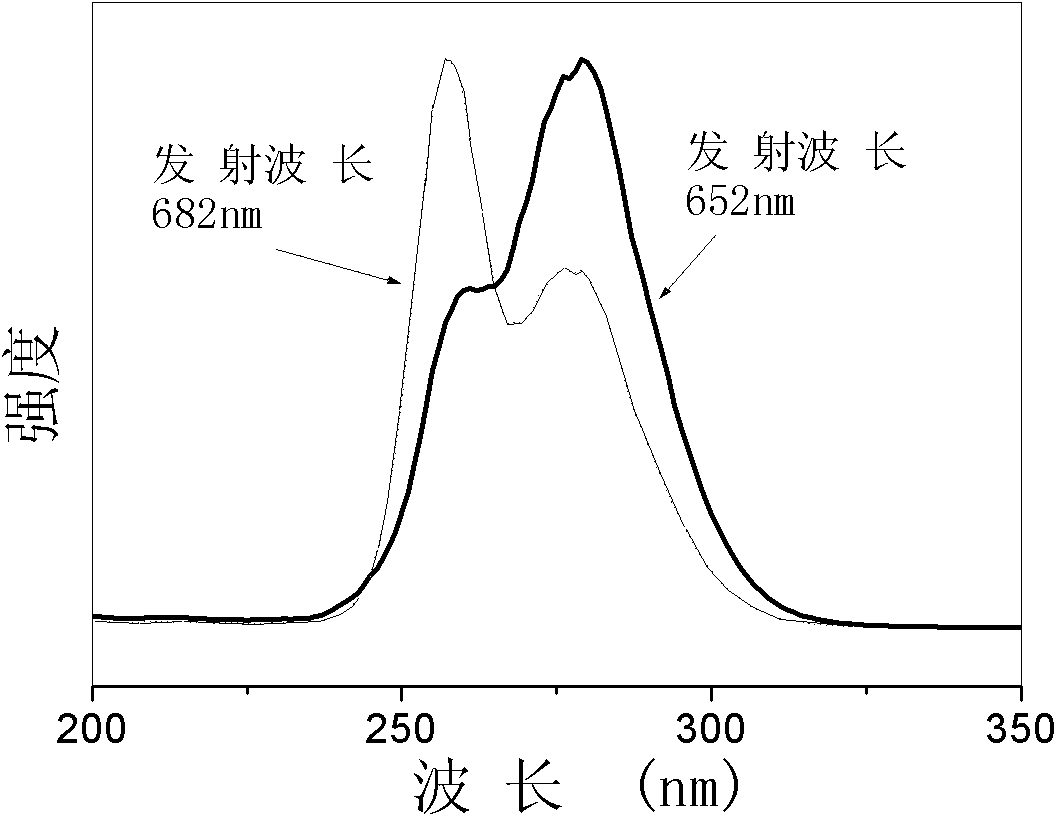

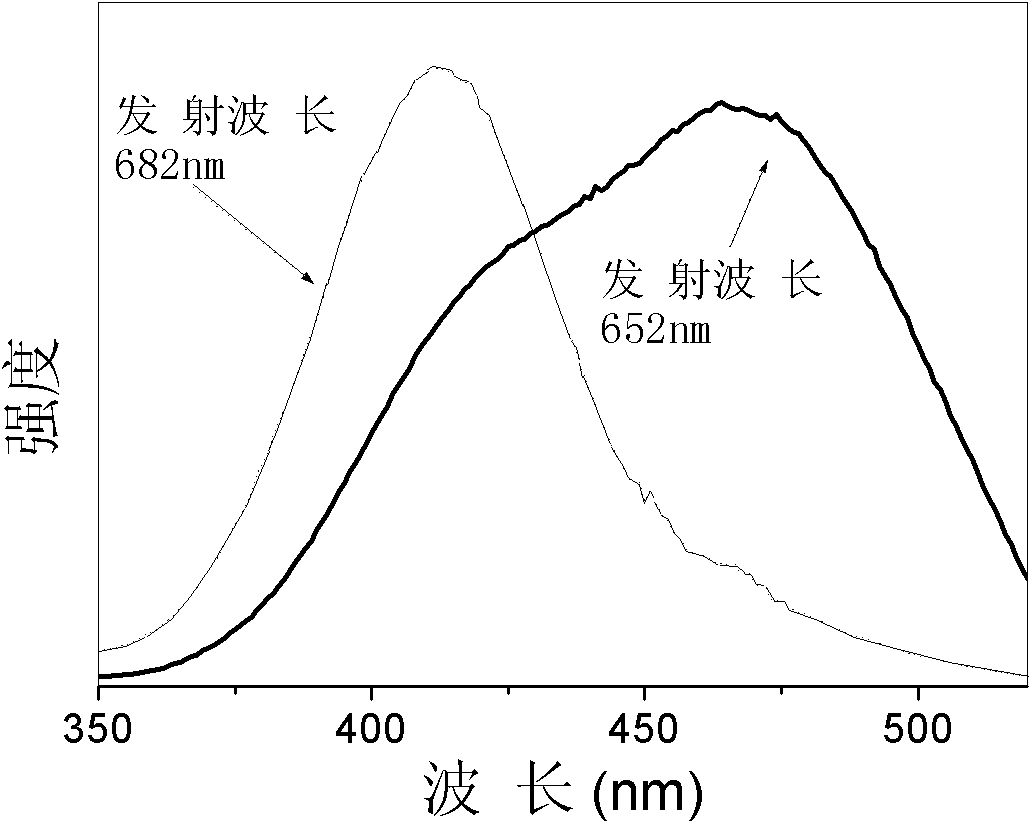

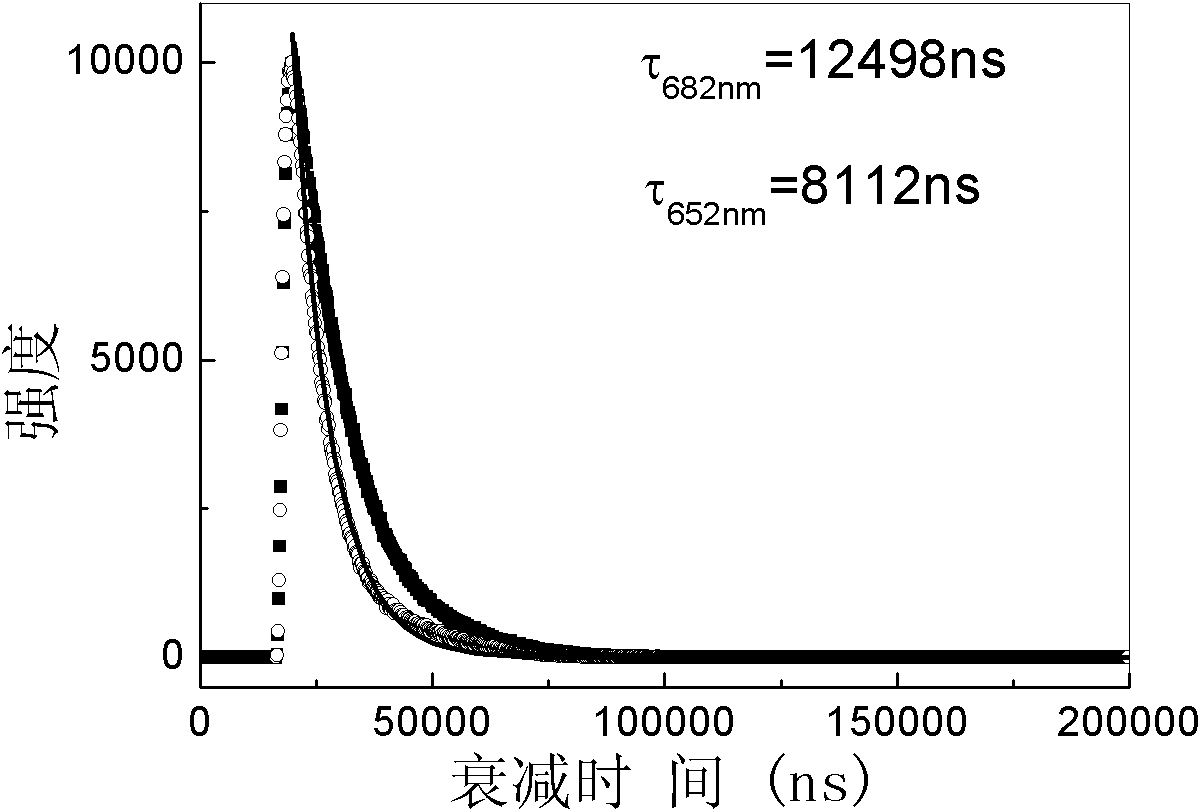

[0021] Choose calcium carbonate, ammonium dihydrogen phosphate and bismuth trioxide as starting materials, press Ca 2(1-x) P 2 o 7 : 2xBi (x=0.05) shown in the molar ratio, i.e. Ca: P: Bi = 1.9: 2: 0.1, three raw materials were weighed respectively, and the total weight of the control mixture was 100 grams. 100 grams of the mixture was mixed by ball milling, put into a corundum crucible, and then put the crucible into a high-temperature electric furnace. Accurately control the heating rate, control the decomposition reaction speed of phosphorus compounds, and prevent the mixture from overflowing from the crucible. o C pre-fired for 10 hours. The pre-fired sample is taken out, ground and mixed again, put into a crucible, and heated at 1100 o C, fired twice for 10 hours, and ground again in the middle. The fired samples were placed at 1100 o CH 2 The bivalent bismuth-doped red fluorescent material was prepared after being treated for 15 minutes. X-ray diffraction analysi...

Embodiment 2

[0023] Choose calcium bicarbonate, ammonium dihydrogen phosphate and bismuth powder as starting materials, press Ca 2(1-x) P 2 o 7 : 2xBi (x=0.00001) shown in the molar ratio, that is, Ca: P: Bi = 1.99998: 2: 0.00002, three raw materials were weighed respectively, and the total weight of the control mixture was 100 grams. 100 grams of the mixture was mixed by ball milling, put into a platinum crucible, and then put the crucible into a high-temperature electric furnace. Accurately control the heating rate, control the decomposition reaction rate of phosphorus compounds, and prevent the mixture from overflowing from the crucible. o C pre-fired for 10 hours. The pre-fired sample is taken out, ground and mixed again, put into a crucible, and heated at 1200 o C, fired twice for 5 hours, and ground again in the middle. The fired samples were placed at 1200°C N 2 +H 2 The bivalent bismuth-doped red fluorescent material was prepared after being treated for 1 hour. X-ray diffra...

Embodiment 3

[0025] Choose calcium oxide, ammonium monohydrogen phosphate and bismuth subcarbonate as starting materials, press Ca 2(1-x) P 2 o 7 : 2xBi (x=0.08) shown in the molar ratio, that is, Ca: P: Bi = 1.84: 2: 0.16, three raw materials were weighed respectively, and the total weight of the control mixture was 100 grams. 100 grams of the mixture was mixed by ball milling, put into a platinum crucible, and then put the crucible into a high-temperature electric furnace. Precisely control the heating rate, control the decomposition reaction speed of phosphorus compounds, and prevent the mixture from overflowing from the crucible. o C pre-fired for 5 hours. The pre-fired sample is taken out, ground and mixed again, put into a crucible, and heated at 1100 oC, fired twice for 20 hours, and ground again in the middle. The fired sample was placed in incompletely burned graphite powder at 1100 degrees Celsius for 1 hour to prepare a bivalent bismuth-doped red fluorescent material. X-ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com