Red Nitrogen oxide fluorescent powder and preparation method thereof

A technology of nitrogen oxides and phosphors, which is applied in the field of phosphors and its preparation, can solve the problems of unfavorable mass production, high price, and easy oxidation, and achieve excellent thermal quenching resistance, low cost, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

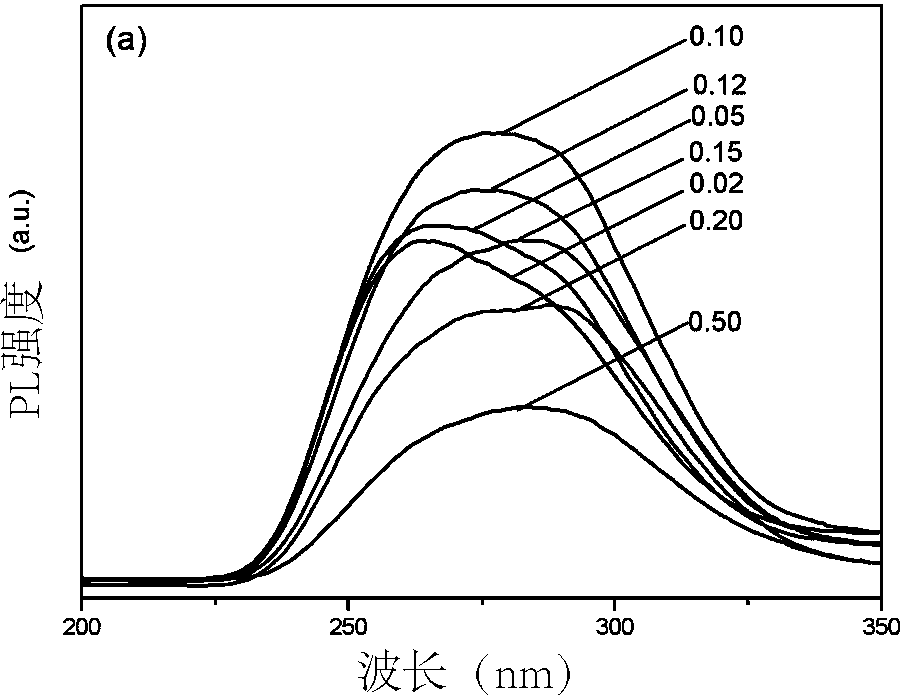

[0035] The invention relates to a red nitrogen oxide fluorescent powder and a preparation method thereof. The phosphor is based on α-Si 3 N 4 The nitride or oxynitride crystal of the crystal structure is formed by solid-dissolving Mn, and the fluorescence with a peak in the wavelength range of 600-750nm will be emitted by irradiating an ultraviolet or visible light excitation source.

[0036] The general chemical formula of the fluorescent powder of the present invention is M (m-2x) / v mn x Si 12-(m+n) al (m+n) o n N 16-n , where M is the metal ion (M=Li, Ca, Mg or Y), v is the valence of the metal M ion, 0<x<1, 0<m≤2(v+x), 0≤n≤2(v +x).

[0037] The characteristics of the nitrogen oxide phosphor powder provided by the present invention mainly lie in:

[0038] (1) Oxynitride phosphor, contained in α-Si 3 N 4 The crystal of the crystal structure has a solid solution of Mn nitride or nitrogen oxide crystal, and the fluorescence with a peak wavelength in the wavelength r...

Embodiment 1-7

[0053] The raw materials used in each embodiment are as follows:

[0054] Si 3 N 4 Powder: α phase content ≥ 92%, O content 0.98%, Fe content ≤ 100ppm, median grain size d 50 =0.32μm

[0055] AlN powder: N content ≥ 32%, Fe content ≤ 100ppm

[0056] CaCO 3 Powder: purity ≥ 99.9%, Fe content ≤ 100ppm

[0057] MnCO 3 Powder: purity ≥ 99.9%, Fe content ≤ 100ppm

[0058] Nitrogen (N 2 ): Purity ≥ 99.9%.

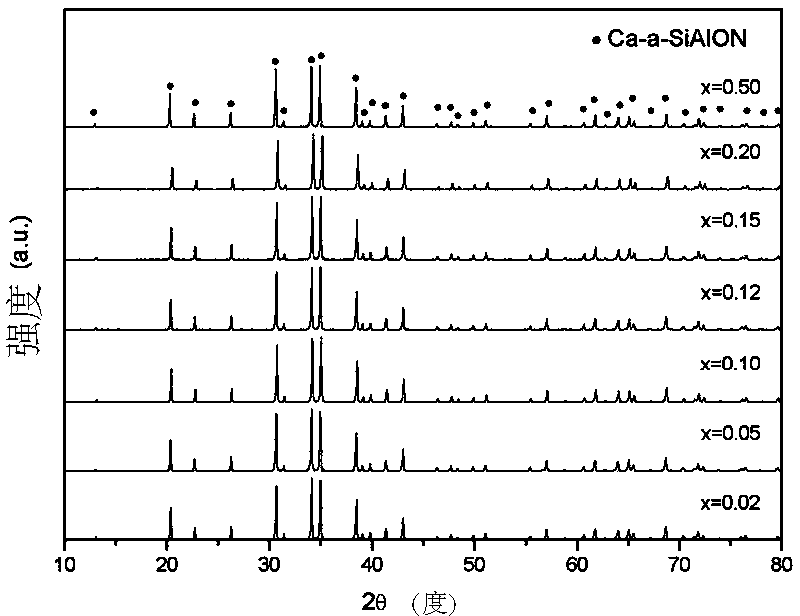

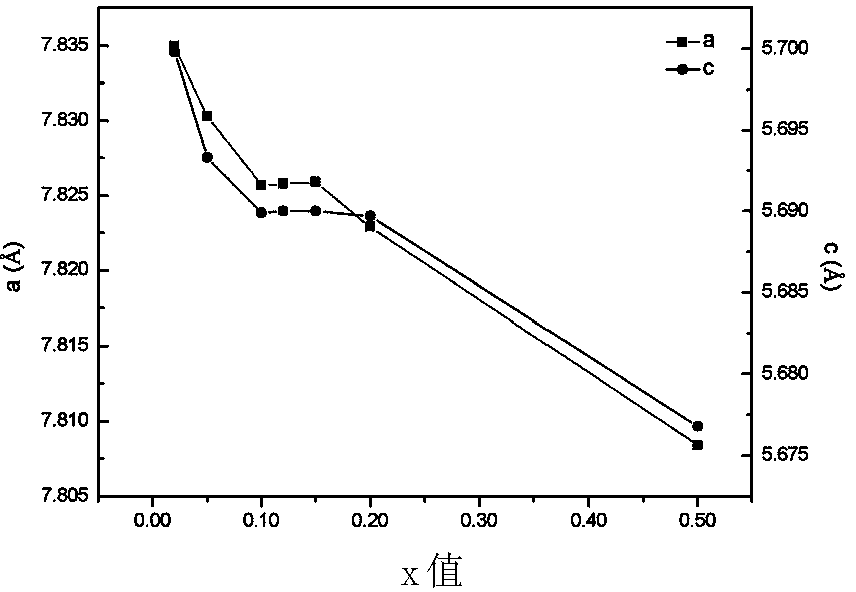

[0059] Formulation design: according to the chemical formula Ca 0.80-x mn x Si 9.6 al 2.4 o 0.8 N 15.2 (Ca-α-SiAlON:Mn 2+ ) designed 7 formulations (x=0.02, 0.05, 0.10, 0.12, 0.15, 0.20, 0.50), and any formulation was processed according to the following methods and steps.

[0060] Weighing: Using the above powder as the starting material, weigh various powder materials in strict accordance with the above stoichiometric ratio.

[0061] Mixing: In a high-purity silicon nitride ball mill tank, use high-purity silicon nitride balls and anhydrous ethanol solvent to w...

Embodiment 8-14

[0076] Use the fluorescent powder prepared in Examples 1-7 to carry out follow-up heat treatment: (1) vacuum the inside of the firing chamber to 10 by a vacuum system -2 Above Pa; (2) Heating from room temperature to 1000°C at a heating rate of 10°C / min; (3) Introducing high-purity nitrogen with a purity of 99.9% at 1000°C to make the pressure in the sintering furnace chamber reach the range of 0.80-0.85MPa; (4) Under the condition of nitrogen pressure of 0.80-0.85MPa (when the internal pressure of the furnace chamber is lower than 0.80MPa, the equipment will automatically replenish the gas, and when the furnace chamber pressure reaches 0.85MPa, the equipment will automatically deflate), at a rate of 10°C / min The heating rate is from 1000°C to 1600°C; (5) Under the condition of nitrogen pressure of 0.80-0.85MPa, heat preservation treatment at 1600°C for 10h; (6) After heat preservation treatment at 1600°C for 10h, naturally cool to room temperature.

[0077] Grinding and crush...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com