Low and medium temperature coal tar cold cutting separation method

A separation method, coal tar technology, applied in tar processing, tar processing by chemical method, tar processing by selective solvent extraction, etc., can solve the problem of low yield of light tar, secondary cracking of coal tar, energy consumption Large and other problems, to achieve the effect of no secondary pollution, cost reduction, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

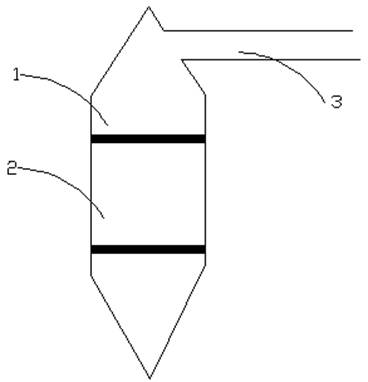

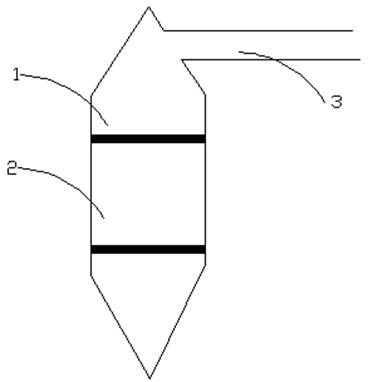

Image

Examples

Embodiment 1

[0028] The bituminous coal in Fugu, Shenmu, Shaanxi is selected as the coal for production, crushed, and then added to the retorting furnace to produce coal tar. The coal first enters the preheating zone and then enters the cracking zone, and as the temperature rises, coal tar is continuously produced, which is stored in the furnace. The tar is gaseous. When the coal is put into the furnace, a complexing agent is injected into the preheating zone of the furnace at 350-400 °C. The amount of the complexing agent added is 10% of the mass of the gaseous coal tar. The gaseous coal tar produced is in the furnace. It reacts with a complexing agent and modifies it to prevent the deep polymerization of coal tar molecules. After the reaction, the gaseous tar is added to cooling water for cooling to become liquid coal tar, and then the moisture in the coal tar is removed to less than 3% to obtain the finished coal tar.

[0029] Weigh the extractants A, B and C according to the mass ratio o...

Embodiment 2

[0031] The bituminous coal was selected as the production coal to prepare coal tar, and the method was the same as that in Example 1, except that the amount of the complexing agent used was 10% of the mass of the gaseous coal tar. Add the obtained coal tar product to the fractionation tower, add A, B, C mixed extractant with a mass ratio of 1:3:5 according to the addition amount of 8wt%, mix and stir evenly, and then stand at about 40-50 ° C for 1 -2h for stratification, and finally the mixed solution is divided into three layers, the upper layer is light tar (yield 60-80wt%, density 0.95g / cm 3 left and right), the middle part is the mixed extractant (yield 95-99wt%), the lower part is heavy tar, and the required components are obtained by separating each layer separately. The obtained light tar and heavy tar (tar pitch) can be directly sold or further modified by hydrogenation to obtain the desired components.

Embodiment 3

[0033] The peat in the Fugu area of Shenmu, Shaanxi was selected as the production coal to prepare coal tar, and the method was the same as that in Example 1, except that the amount of the complexing agent used was 6% of the gaseous coal tar quality. Add the obtained coal tar product to the fractionation tower, add A, B, C mixed extractant with a mass ratio of 1:3:1.7 according to the addition amount of 6wt%, mix and stir evenly, and then stand at about 40-50 ° C for 1 -2h for stratification, and finally the mixed solution is divided into three layers, the upper layer is light tar (yield 60-80wt%, density 0.95g / cm 3 left and right), the middle part is heavy tar, the lower part is mixed extractant (yield 95-99wt%), light tar does not contain extractant, and the required components are obtained by separating each layer. The obtained light tar and heavy tar (tar pitch) can be directly sold or further modified by hydrogenation to obtain the desired components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com