Transparent self-cleaning SiO2 anti-fogging coating and preparation method thereof

An anti-fogging coating and self-cleaning technology, applied in the field of transparent self-cleaning SiO2 anti-fogging coating and its preparation, can solve the problems of many components, limited scope of application, difficult to achieve, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

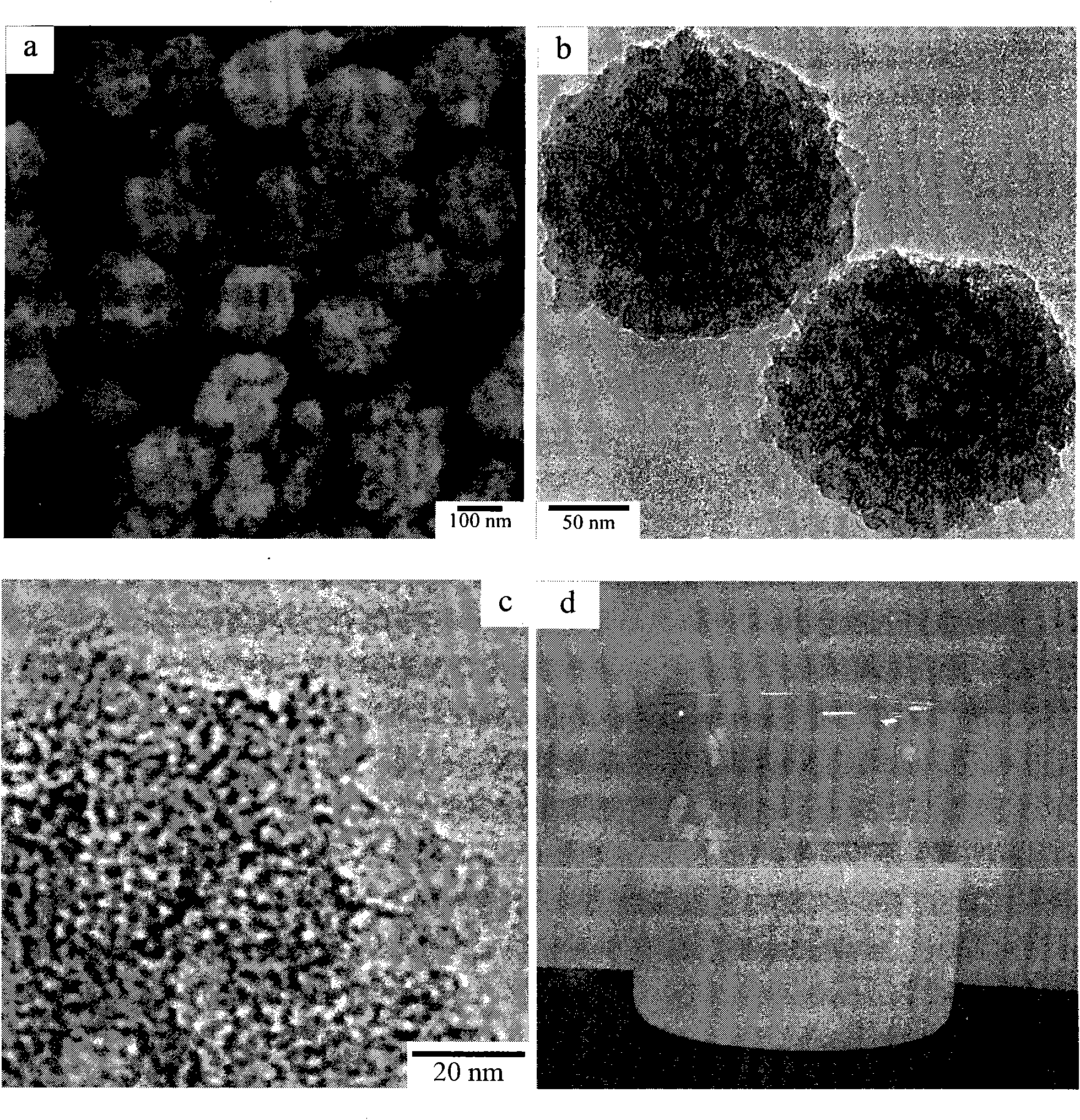

[0060] Hierarchical mesoporous SiO 2 Preparation of nanoparticles:

[0061] (1) Dissolve 0.3-0.7 g of cetyltrimethylammonium bromide in 50-100 ml of distilled water (conductivity 18.2 MΩ) at 20-25 degrees Celsius, and stir for 10-30 minutes to form a homogeneous solution;

[0062] (2) the ammoniacal liquor (the mass percent composition of ammonia is 25%) of 0.6~1 milliliter respectively, the dehydrated alcohol of 5~25 milliliters and the ether of 10~30 milliliters join in the solution that step (1) obtains, in At a magnetic stirring speed of 600-1500 rpm, stir for 2-10 minutes, and form a transparent and colorless emulsion in 10-30 minutes;

[0063] (3) Add 1.5-3 ml of tetraethoxysilane (purity not less than 99.9%) to the transparent colorless emulsion obtained in step (2), seal and keep stirring for 3-8 hours;

[0064] (4) filtering the solid precipitate obtained by the reaction in step (3), washing with water, and drying in an oven at a temperature of 60 to 80 degrees Cels...

Embodiment 2

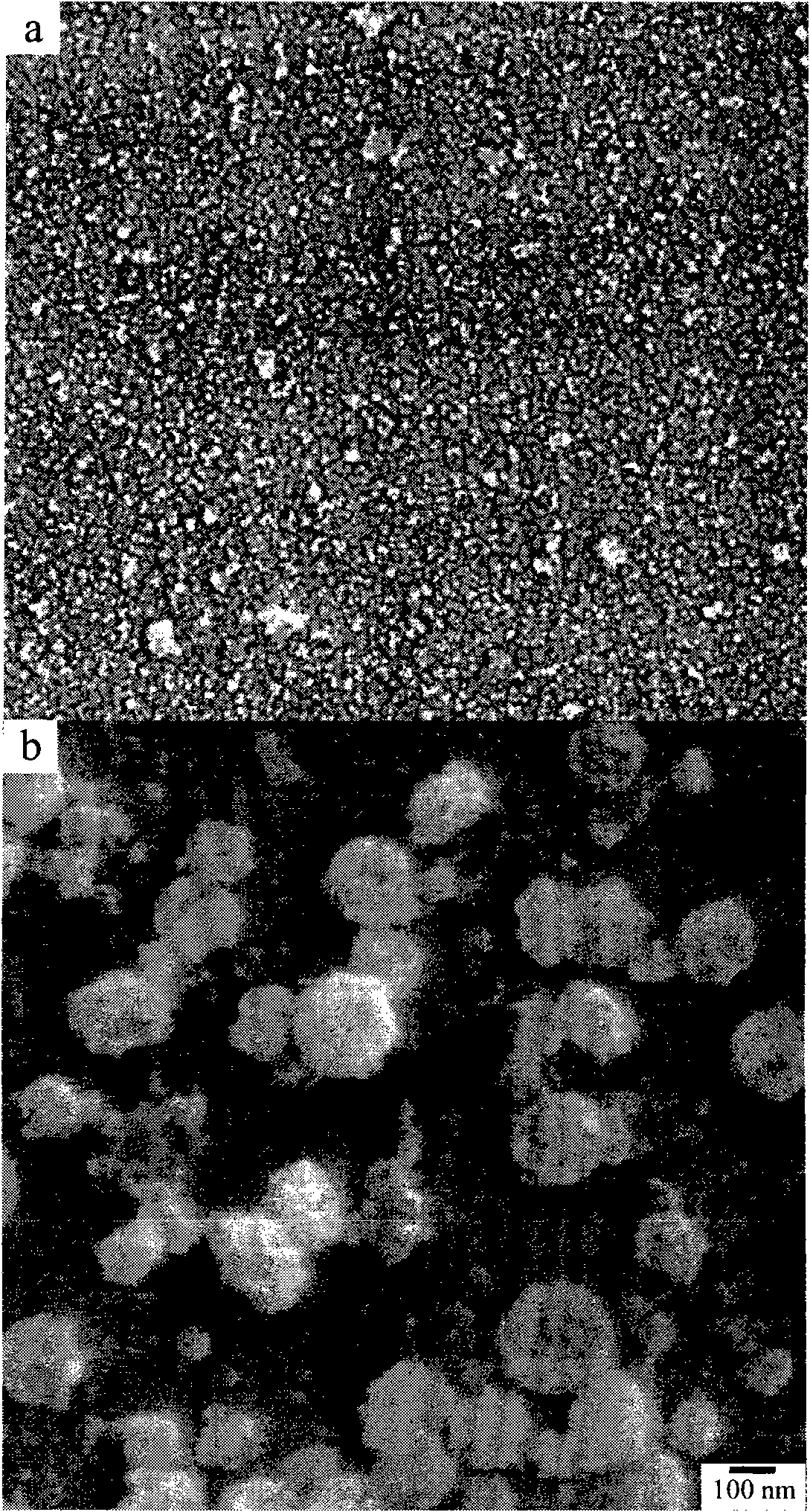

[0069] A layer of mesoporous SiO 2 Superhydrophilic and transparent self-cleaning SiO with rough structure on the surface composed of nanoparticles 2 Preparation of anti-fog coating: using the SiO with hierarchical mesoporous structure prepared in Example 1 with a mass percentage of 0.2-0.6% 2 Nano particle suspension is used as raw material, and its preparation method comprises the following steps:

[0070] (1) the glass piece is immersed in the newly prepared Pirhana solution (mass concentration is about 98% H 2 SO 4solution with a mass concentration of approximately 30% H 2 o 2 The mixture of solutions, where, H 2 SO 4 solution with H 2 o 2 The volume ratio of the solution is 7: 3), after soaking for 5 to 20 minutes, take out and wash with distilled water, and blow dry with nitrogen;

[0071] (2) Immerse the glass sheet dried with an inert gas in step (1) into an aqueous solution of polydiallyldimethylammonium chloride with a concentration of 1 to 3 mg / mL for 2 to ...

Embodiment 3

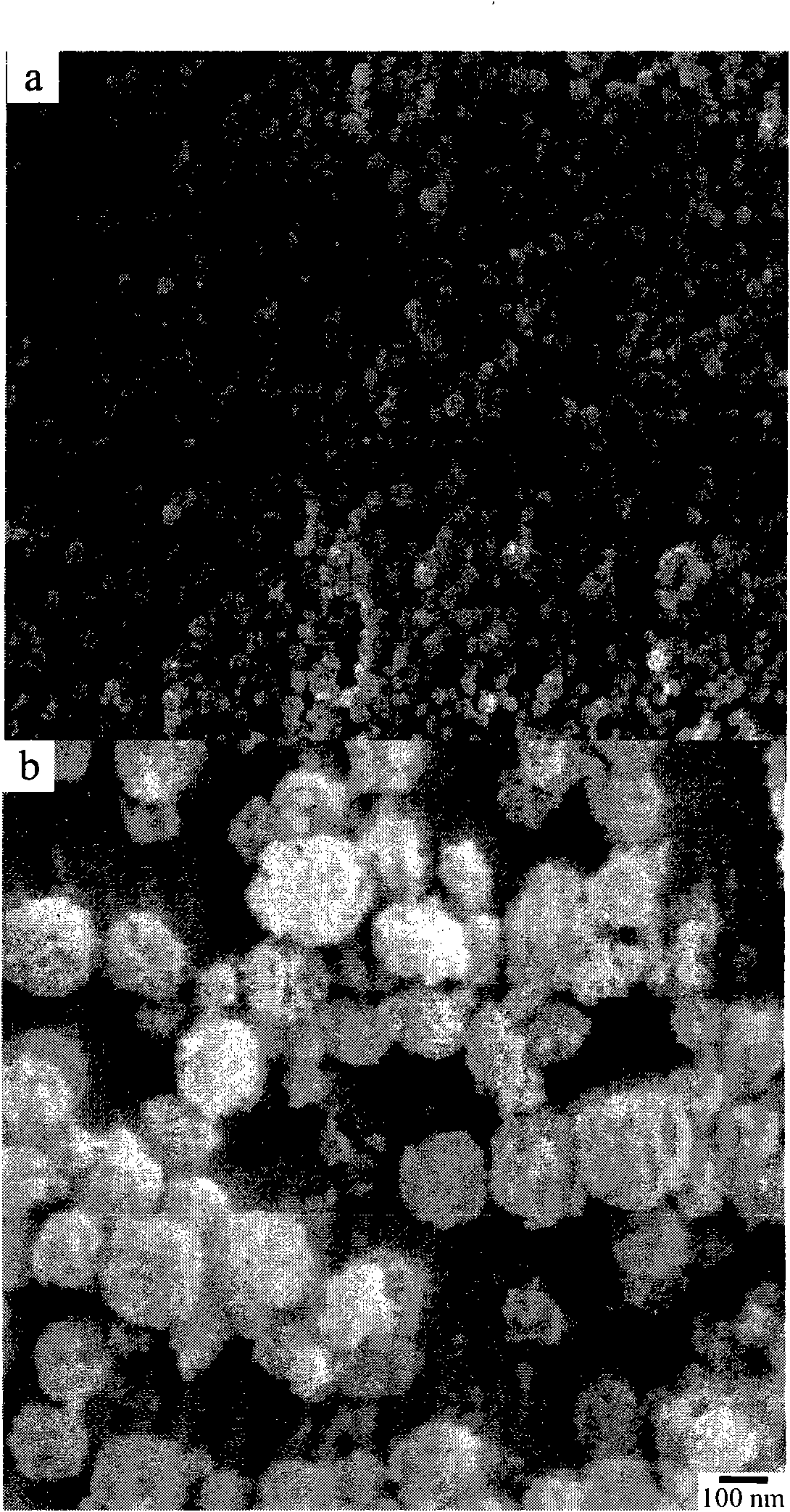

[0077] Two-layer hierarchical mesoporous SiO 2 Superhydrophilic and transparent self-cleaning SiO with rough structure on the surface composed of nanoparticles 2 Preparation of anti-fog coating: using SiO with hierarchical mesoporous structure prepared in Example 1 with a mass percentage of 0.2-0.6% 2 Nano particle suspension is used as raw material, and its preparation method comprises the following steps:

[0078] (1) the glass piece is immersed in the newly prepared Pirhana solution (mass concentration is about 98% H 2 SO 4 solution with a mass concentration of approximately 30% H 2 o 2 The mixture of solutions, where, H 2 SO 4 solution with H 2 o 2 The volume ratio of the solution is 7: 3), after soaking for 5 to 20 minutes, take out and wash with distilled water, and blow dry with nitrogen;

[0079] (2) Immerse the glass sheet dried with an inert gas in step (1) into an aqueous solution of polydiallyldimethylammonium chloride with a concentration of 1 to 3 mg / mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com