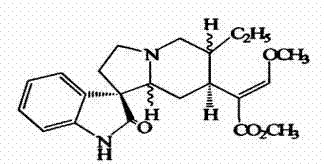

Preparation method for high purity rhynchophylline

A high-purity technology for rhynchophylline, which is applied in the field of preparation of high-purity rhynchophylline, can solve the problems of poor thermal stability of rhynchophylline, easy decomposition, and low yield of rhynchophylline, etc., and achieves short preparation period and high production volume. Large, the effect of reducing the loss of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Uncaria medicinal material is crushed to 20 meshes, 10kg is taken, 4 times the amount of 5% sodium carbonate solution is added for ultrasonic extraction for 1 hour, the liquid is filtered off, and then 5 times the amount of dichloromethane is added for ultrasonic extraction 3 times, the dichloromethane extract is used to recover the reagent and concentrated to 100ml. Take chloroform, methanol, and water, mix and layer them in a separatory funnel at a ratio of 6:7:3, take the upper phase and adjust the pH to 7.5 with triethylamine, make it a stationary phase, inject it into a high-speed countercurrent chromatography column, and make it full , turn on the host, rotate at 700rpm, pump into the lower phase, after dynamic balance, adjust the flow rate to 2ml / min, and inject the concentrated solution from the injection valve at the same time, the ultraviolet detector will monitor online, collect the target components, refrigerate and crystallize, filter out and dry, 980 mg of...

Embodiment 2

[0021] Uncaria medicinal material is crushed to 20 meshes, 10kg is taken, and 5 times the amount of 5% sodium carbonate solution is added for ultrasonic extraction for 1 hour, the liquid is filtered off, and then 7 times the amount of dichloromethane is added for ultrasonic extraction twice, and the dichloromethane extract is used to recover reagents and concentrated to 150ml. Take chloroform, methanol, and water, mix and layer them in a separating funnel at a ratio of 8:5:3, take the upper phase and adjust the pH to 8 with triethylamine, make it a stationary phase, inject it into a high-speed countercurrent chromatography column, make it full, and turn it on The main engine rotates at 1000rpm, and pumps into the lower phase. After dynamic balance, the flow rate is adjusted to 4ml / min. At the same time, the concentrated solution is injected from the injection valve, and the ultraviolet detector is monitored online. The target components are collected, refrigerated and crystalli...

Embodiment 3

[0024] Uncaria medicinal material is crushed to 20 meshes, 10kg is taken, 4 times the amount of 5% sodium carbonate solution is added for ultrasonic extraction for 1 hour, the liquid is filtered off, and then 5 times the amount of dichloromethane is added for ultrasonic extraction 3 times, the dichloromethane extract is used to recover the reagent and concentrated to 100ml. Take n-hexane, ethyl acetate, methanol, and water in a ratio of 3:5:2:6, mix and layer in a separatory funnel, remove the phase and adjust the pH to 7.5 with triethylamine, make it a stationary phase, and inject it into a high-speed countercurrent In the chromatographic column, make it full, turn on the host, rotate at 800rpm, pump into the upper phase, after dynamic equilibrium, adjust the flow rate to 1ml / min, and inject the concentrated solution from the injection valve at the same time, and the ultraviolet detector will monitor online to collect the target components. Refrigerate and crystallize, filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com