Main structure

A main structure, concrete structure technology, applied in the direction of structural elements, building components, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

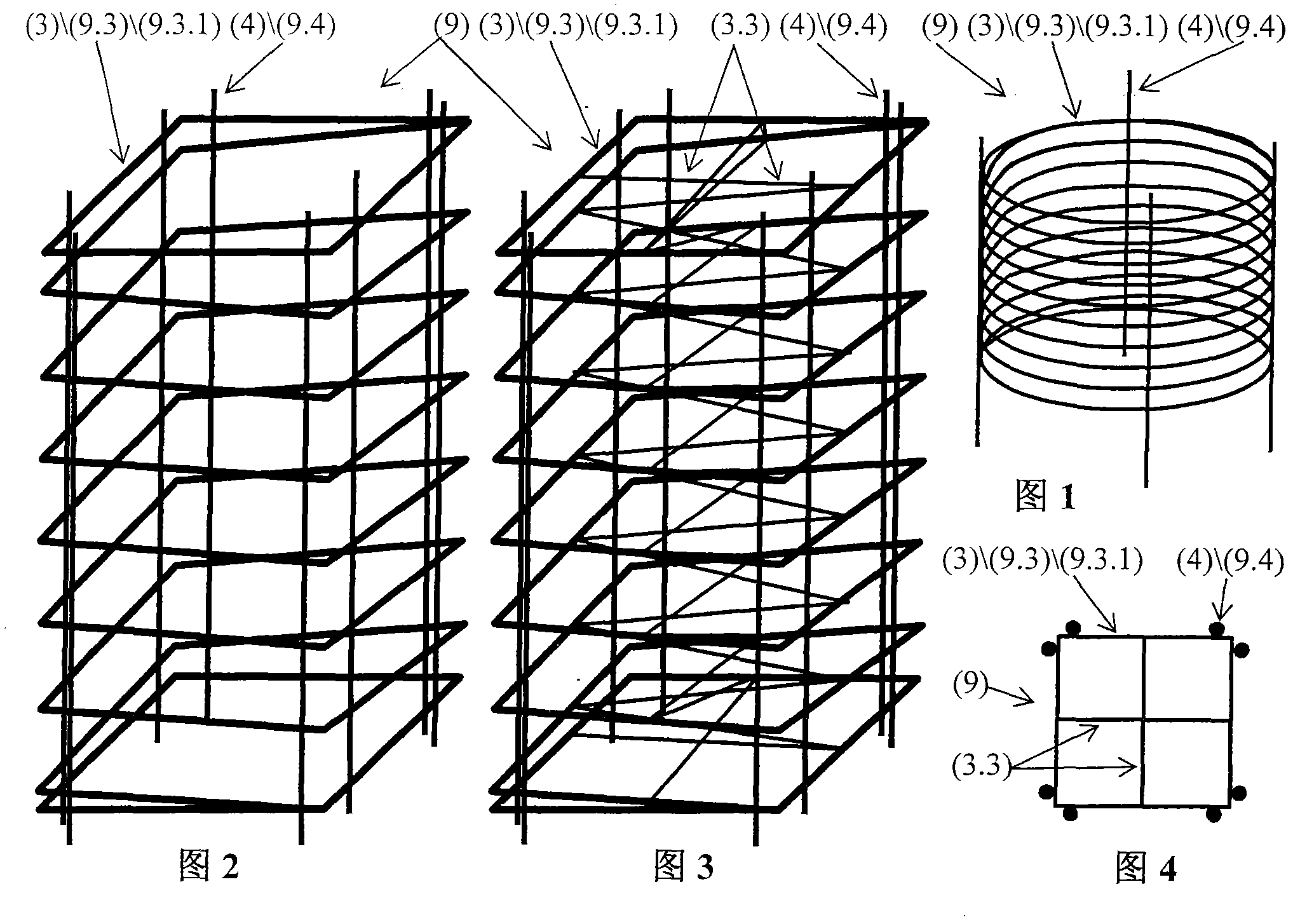

[0199] Example 1. from figure 1 , figure 2 , image 3 with Figure 4 It can be seen that it is a circular or rectangular prefabricated overall stirrup cage frame (9) with node segments of spiral stirrups. It is characterized in that it includes cage spiral stirrups (9.3.1), cage vertical bars (9.4), and the cage stirrups (9.3) and cage vertical bars (9.4) are connected by welding. The diameter of the cage spiral stirrup (9.3.1) is between 1-32 mm; the spacing between the stirrups is between 40-60 mm; Less than 250mm. Steel materials for cage spiral stirrups (9.3.1) and cage vertical bars (9.4) include one of the following combinations: HPB235, HRB335, HRB400, RRB400. The "minimum reinforcement ratio eigenvalue λv" or "volume reinforcement ratio ρv" of the stirrup (3) is greater than the "Code for Design of Concrete Structures" GB50010-2002 or "Code for Seismic Design of Buildings" GB 50010-2002 or "High-Rise Building Structure More than 1.8 times the specified value of...

Embodiment 2

[0200] Example 2. from figure 1 , figure 2 , image 3 with Figure 4 It can be seen that it is a circular or rectangular prefabricated overall stirrup cage frame (9) with node segments of spiral stirrups. It is characterized in that: the cage spiral stirrup (9.3.1) adopts inorganic non-metallic fiber or fiber reinforced composite material (FRP) or advanced composite material (ACM); wherein the inorganic non-metallic fiber includes one of the following materials: basalt fiber , carbon fiber, glass fiber, ceramic fiber. All the other features are the same as in Example 1.

Embodiment 3

[0201] Example 3. from figure 1 , figure 2 , image 3 with Figure 4 It can be seen that it is a circular or rectangular prefabricated overall stirrup cage frame (9) with node segments of spiral stirrups. It is characterized in that: the cage spiral stirrup (9.3.1) adopts a reinforcing material composed of metal material and non-metal fiber material, that is, metal and non-metal fiber composite material (11). All the other features are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com