New preparation method of housefly larva chitosan

A technology of fly maggot chitosan and a new method, applied in the field of biochemistry, can solve the problems of low separation efficiency and achieve the effect of low energy consumption and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 Fly maggot chitosan prepares new method

[0025] Include the following steps:

[0026] 1) The pretreatment of halogenated fly maggots is to remove large debris such as sawdust, flies, and mud, leaving clean fly maggot shells, which are placed in an oven and dried to constant weight.

[0027] 2) Take a certain amount of fly maggot shells, stir and soak with 3% hydrochloric acid for 10 hours, wash with water, then replace with 3% hydrochloric acid solution, repeat stirring and soaking once, and wash with water. .

[0028] 3) Stir and soak the fly maggot shells with 5% sodium hydroxide solution for 15 hours to remove internal organs and other wastes.

[0029] 4) The fly maggot shells are soaked in a 2% potassium permanganate solution, placed in a dark place, stirred and reacted for 4 hours, washed with water, stirred and soaked with a 2% oxalic acid solution for 1 hour, washed with water, and then Be that the oxalic acid solution of 2% is soaked 3 hours aga...

experiment example

[0061] Experimental example Effect of microwave heating method and ordinary heating method on chitin deacetylation of fly maggots

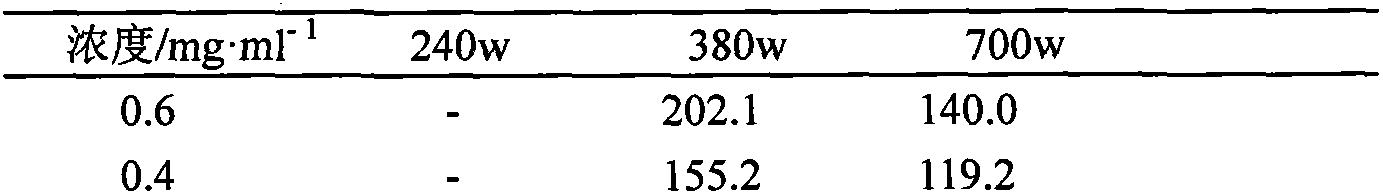

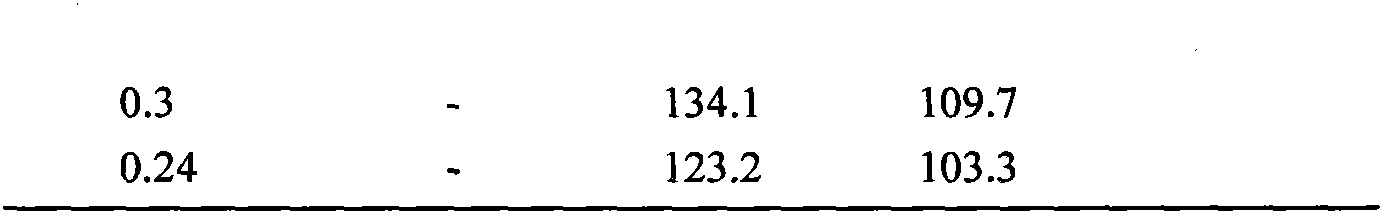

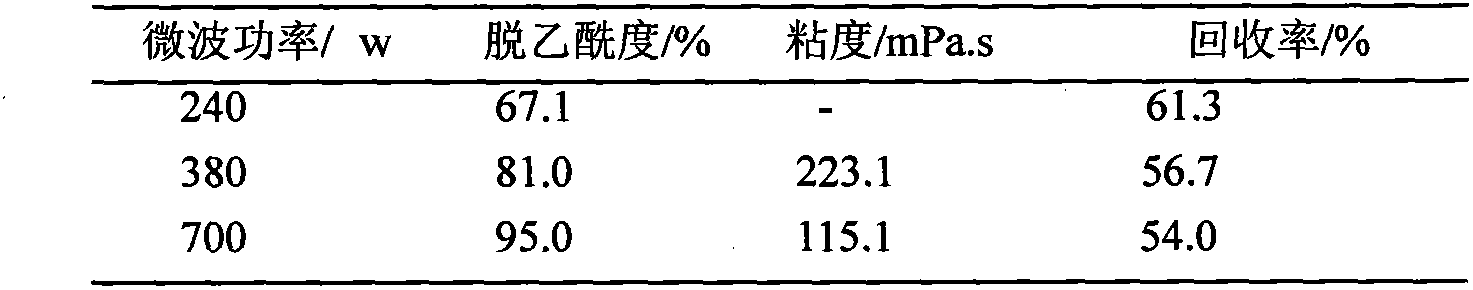

[0062] Weigh 2 parts of 1.50g crude fly maggot chitin and put them into beakers respectively, add 100ml of 50% sodium hydroxide solution, put it on the electric furnace and heat it directly, adjust the power to 1800w, and keep stirring to prevent uneven heating And make concentrated lye splash. After washing, dry and measure the degree of deacetylation and viscosity. The following data are obtained, as shown in Table 6:

[0063] The degree of deacetylation, viscosity, recovery rate of table 6 electric furnace direct heating preparation fly maggot chitosan

[0064]

[0065] Comparing Table 6 and Table 4, it can be seen that the degree of deacetylation of chitosan prepared by common heating method is much lower than that of microwave heating method with much smaller heating time and heating power. Microwave method is heated at 380w The degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com